15 years one-stop China custom CNC machining parts factory

500 |

Published by VMT at May 31 2023

500 |

Published by VMT at May 31 2023

Micro hole machining plays a pivotal role in various industries, meeting the demand for highly precise and miniaturized components. With the growing need for smaller, complex parts, it becomes crucial to understand the requirements and challenges associated with micro hole machining. This article explores the significance of micro hole machining, the considerations for successful implementation, the emerging technologies, and best practices.

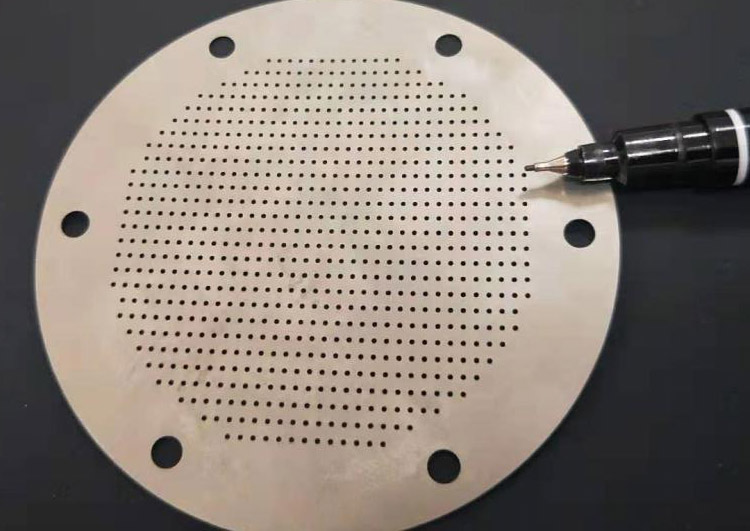

Micro hole machining refers to the process of creating small-diameter holes, typically ranging from a few micrometers to a few millimeters, in various materials. These intricate holes find applications in a wide range of industries, including medical, electronics, and automotive sectors. As technology advances and components become smaller, the demand for precision engineering grows, making micro hole machining an indispensable process.

Micro hole machining, also known as micro drilling or micro machining, refers to the process of creating small-diameter holes in materials with high precision and accuracy. It involves using specialized tools and techniques to drill or cut tiny holes, typically ranging from a few micrometers to a few millimeters in diameter. Micro hole machining is essential in industries where miniaturized components and precise engineering are required, such as the medical, electronics, and automotive sectors. The process involves careful consideration of factors like material selection, tooling, cutting parameters, and addressing challenges like tool breakage, chip evacuation, and achieving the desired surface finish. By optimizing the process and adopting best practices, manufacturers can produce intricate and high-quality micro holes to meet the demands of various applications.

0.2 micropore refers to a small hole with a diameter of about 0.2 mm, which is equivalent to about 1/3 of a human hair. Because of its very small size, it requires very high-precision processing technology to realize.

And numerical control machining is a kind of processing technology that can meet this high-precision requirement. CNC machining uses computer programs to control the movement of tools and workpieces, resulting in precise part machining. Compared with traditional manual processing methods, CNC machining has higher precision, faster production speed and better repeatability.

For the processing of 0.2 micro-hole parts, CNC lathes and CNC milling machines are common processing equipment. During the processing, it is necessary to select appropriate tools and process parameters, and use high-precision measuring instruments to inspect the parts to ensure that the processing quality meets the requirements.

In addition to the requirements of processing technology, the choice of materials is also very important. For 0.2 micro-hole parts, the material must have sufficient hardness and wear resistance to ensure that the hole wall will not be damaged by the tool and maintain sufficient precision.

In conclusion, CNC machining is an efficient, precise and reliable method of manufacturing 0.2 microporous parts. Through reasonable processing technology and material selection, high-quality parts that meet the requirements can be produced.

In the world of precision engineering, the demand for machining ultra-small holes has grown significantly. One particular challenge involves the CNC machining of 0.2 micron-sized holes, which requires specialized techniques and considerations. In this blog article, we will explore the key requirements that customers should be aware of when it comes to CNC machining of such tiny holes.

1. Understanding the Importance of Precision

When machining 0.2 micron-sized holes, precision is of utmost importance. Even the slightest deviation can significantly impact the functionality and performance of the final product. Customers should emphasize the need for precision machining, ensuring that the finished holes meet the required dimensions and tolerances.

The choice of material plays a crucial role in CNC machining of micro-sized holes. Certain materials, such as high-strength alloys or brittle materials, may pose challenges due to their hardness or tendency to deform. It is essential for customers to communicate their material requirements to the CNC machining service provider, ensuring that they have the expertise and capabilities to work with the desired material.

3. Specialized Tooling and Equipment

Machining such small holes requires specialized tooling and equipment. Customers should inquire about the CNC machine's capabilities and the availability of micro-drills and cutting tools suitable for 0.2 micron-sized holes. The CNC machining service provider should possess high-precision machines with minimal runout and the ability to maintain stability during the machining process.

4. Cutting Parameters and Techniques

Determining the appropriate cutting parameters and techniques is crucial for successful CNC machining of 0.2 micron-sized holes. Factors such as cutting speed, feed rate, and depth of cut need to be optimized to achieve the desired results. Customers should discuss these parameters with the machining service provider to ensure that they have the expertise to optimize the machining process for such tiny holes.

5. Chip Evacuation

Proper chip evacuation is essential when machining micro-sized holes. Due to their small size, chips can easily accumulate and affect the machining process. Customers should inquire about the chip evacuation methods employed by the CNC machining service provider. Techniques such as through-spindle coolant or air blasts can help ensure efficient chip removal and prevent chip-induced tool breakage.

6. Quality Control and Inspection

Customers should emphasize the importance of quality control and inspection throughout the CNC machining process. Inspecting the finished holes for dimensional accuracy, surface finish, and overall quality is crucial. The CNC machining service provider should have robust quality control measures in place, such as precision measurement tools and inspection techniques, to ensure that the finished holes meet the required specifications.

7. Collaboration and Communication

Effective collaboration and communication between the customer and the CNC machining service provider are key to successful machining of 0.2 micron-sized holes. Customers should clearly communicate their requirements, expectations, and any specific challenges they anticipate. Regular communication throughout the machining process allows for adjustments, feedback, and addressing any concerns that may arise.

Conclusion

Machining 0.2 micron-sized holes through CNC machining requires attention to detail, specialized tooling, precision equipment, and optimized cutting parameters. By understanding and communicating the key requirements outlined above, customers can ensure a successful CNC machining process for these ultra-small holes. Choosing a reliable and experienced CNC machining service provider who specializes in micro-machining is crucial for achieving the desired results.

Precision Engineering

In industries where accuracy and precision are paramount, micro hole machining offers the ability to create tiny holes with high repeatability and dimensional accuracy. This precision is crucial for applications where even the slightest deviation can impact performance, such as medical implants or electronic components.

Miniaturization Trends

The trend towards miniaturization, driven by the need for compact and lightweight devices, necessitates the production of smaller components. Micro hole machining enables the creation of intricate designs and complex features, allowing manufacturers to keep up with the demands of miniaturization.

Successful micro hole machining requires careful consideration of several factors. These include:

Material Selection

Different materials have varying properties and respond differently to machining processes. Choosing the right material is essential to ensure optimal hole quality, tool life, and process stability. Factors like hardness, thermal conductivity, and machinability need to be taken into account.

Micro hole machining demands specialized tooling and equipment designed for small-scale operations. Micro drills, end mills, and other cutting tools with diameters in the micrometer range are required. The CNC machine itself should have high rigidity and precision to achieve accurate results.

Cutting Parameters

Determining the appropriate cutting parameters, such as cutting speed, feed rate, and depth of cut, is critical for successful micro hole machining. These parameters directly affect tool life, chip evacuation, and surface finish. Careful optimization and adjustment are necessary for each specific application.

Micro hole machining poses several challenges that need to be addressed to achieve optimal results. Some common challenges include:

Tool Breakage

Due to the small size of the tools used in micro hole machining, tool breakage is a common issue. Proper tool selection, tool material, and minimizing tool runout can help mitigate this problem. Regular inspection and replacement of worn tools are necessary to maintain process stability.

Chip Evacuation

Removing chips from micro holes can be challenging due to their small size. Inadequate chip evacuation can lead to poor hole quality and tool damage. Using proper cutting techniques, coolant, and chip evacuation strategies, such as through-spindle coolant or peck drilling, can help ensure efficient chip removal.

Micro hole machining requires excellent surface finish to meet the precision requirements. Factors such as tool runout, cutting parameters, and tool wear can affect surface roughness. Fine-tuning the machining parameters and employing appropriate finishing operations, like reaming or honing, can improve surface quality.

Micro hole machining finds widespread applications in various industries, including:

In the medical field, micro hole machining is used to create tiny holes in medical implants, catheters, and surgical instruments. These holes enable precise drug delivery, fluid flow, or implant integration, contributing to advancements in medical technology.

Electronics and Semiconductors

Micro holes are essential in the production of electronic components, such as printed circuit boards (PCBs), microelectromechanical systems (MEMS), and semiconductor devices. They facilitate electrical connections, thermal management, and sensor integration in compact devices.

In the automotive industry, micro hole machining is employed for fuel injectors, turbochargers, and engine components. These small holes enable efficient fuel delivery, precise airflow control, and enhanced engine performance.

Laser Micro machining

Laser technology offers precise and non-contact machining capabilities, making it ideal for micro hole drilling. It allows for high aspect ratios, intricate geometries, and the ability to work with a wide range of materials.

Electrochemical Machining

Electrochemical machining (ECM) is a non-traditional machining process that uses an electrolyte to dissolve material from the workpiece. It offers excellent precision, burr-free results, and the ability to machine complex profiles.

Micro EDM

Micro electrical discharge machining (EDM) employs electrical discharges to erode the workpiece material. It enables the creation of intricate micro features with high accuracy, making it suitable for micro hole machining.

Use micro-CNC mill or milling head for micro-scale milling, which can produce high-precision, high-quality surface cavities.

No need to use any kind of advanced processing, choose the appropriate tool material for the city's needs, and combine the appropriate processing factors and processing technology to ensure the feasibility and precision of the processing plant. At the same time, the quality control of the progress of the demand, the size, the shape, the surface roughness and the degree of surface roughness and other indicators of the comprehensive inspection, ensure that the processing quality conforms to the requirements.

To ensure successful micro hole machining, the following best practices should be considered:

Design Considerations

Designing components with micro hole machining in mind can significantly improve the process. Factors such as hole location, accessibility, and tolerance requirements should be taken into account during the design phase.

Process Optimization

Optimizing the machining process involves fine-tuning cutting parameters, selecting appropriate tooling, and ensuring efficient chip evacuation. Continuous monitoring and adjustment of the process parameters can enhance productivity and hole quality.

Implementing effective quality control measures is essential for micro hole machining. Inspection techniques, such as microscopy, profilometry, and non-destructive testing, should be employed to verify hole dimensions, surface finish, and overall quality.

Micro hole machining is a critical process for meeting the demands of precision engineering and miniaturization in various industries. By understanding the importance of micro hole machining, considering key factors, addressing challenges, and adopting best practices, manufacturers can achieve high-quality results. With advancements in technology and a focus on continuous improvement, micro hole machining will continue to play a vital role in producing intricate and high-precision components.

1. What is micro hole machining?

Micro hole machining refers to the process of creating small-diameter holes in materials with high precision and accuracy, typically ranging from a few micrometers to a few millimeters.

2. What are the applications of micro hole machining?

Micro hole machining is widely used in industries such as medical, electronics, and automotive. It finds applications in medical implants, PCBs, fuel injectors, and more.

3. What are the challenges in micro hole machining?

Challenges in micro hole machining include tool breakage, chip evacuation, and achieving the desired surface finish due to the small scale of the process.

4. How can I optimize the micro hole machining process?

Optimizing the process involves selecting the right cutting parameters, tools, and ensuring efficient chip evacuation. Continuous process monitoring and adjustment are key.

5. What are the emerging technologies in micro machining?

Emerging technologies in micro machining include laser micromachining, electrochemical machining (ECM), and micro electrical discharge machining (EDM).

6. What are the challenges in CNC machining of 0.2 micron-sized holes?

Machining such small holes poses challenges in terms of precision, material selection, chip evacuation, and optimizing cutting parameters to achieve the desired results.

7. How important is precision in machining 0.2 micron-sized holes?

Precision is crucial as even the slightest deviation can significantly impact the functionality and performance of the final product. Machining must meet the required dimensions and tolerances.

8. What should customers consider when selecting a CNC machining service provider for micro-sized holes?

Customers should consider the provider's expertise, specialized tooling and equipment, chip evacuation methods, and quality control measures to ensure successful machining of micro-sized holes.

9. How can customers ensure effective communication with the CNC machining service provider?

Customers should clearly communicate their requirements, expectations, and any anticipated challenges. Regular communication throughout the process allows for adjustments and addressing concerns.

10. What role does material selection play in CNC machining of 0.2 micron-sized holes?

Material selection is crucial as different materials may pose challenges due to their hardness or tendency to deform. It is important to work with a provider experienced in machining the desired material.