15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

9455 |

Published by VMT at Aug 14 2023

9455 |

Published by VMT at Aug 14 2023

Copper, a metal widely used for its conductivity and versatility, often undergoes intriguing color changes, from green to black. These transformations can be perplexing, prompting questions about the underlying causes and potential remedies. In this article, we delve into the fascinating world of copper's color changes, exploring the factors responsible for the shift, and providing insights into how to address this phenomenon.

Table of Contents

Introduction

Understanding the Color Changes

Why Copper Turns Green

Factors Leading to Green Patina

Why Copper Turns Black

Factors Contributing to Blackening

Solutions for Green Patina

Preventing Green Patina

Solutions for Blackening

Preventing Blackening

Preserving the Original Appearance

Embracing the Natural Patina

Conclusion

Frequently Asked Questions

Introduction

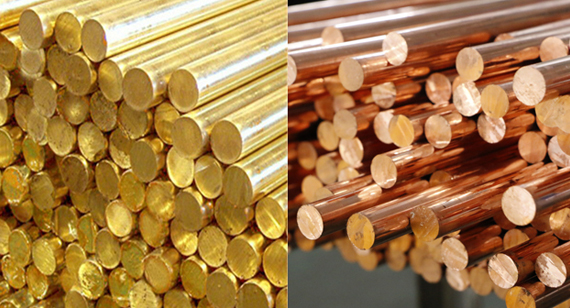

Copper material, known for its distinctive reddish hue, is no stranger to color transformations. It can turn both green and black, leaving many intrigued by the underlying causes and potential solutions. This article aims to shed light on the science behind these color changes, offering insights into why they occur and how to address them effectively.

Understanding the Color Changes

Copper's color changes are primarily due to the formation of various compounds on its surface. These compounds result from the metal's interaction with external factors such as air, moisture, pollutants, and even human touch. Over time, these interactions lead to the development of distinct colors on the copper's surface.

The green color that copper sometimes takes on is a result of the formation of copper carbonate. This compound forms when copper reacts with oxygen, moisture, and carbon dioxide from the air. The resulting green layer, known as patina, not only adds a unique aesthetic but also acts as a protective barrier against further corrosion.

Factors Leading to Green Patina

Several factors contribute to the development of green patina on copper. Humidity, exposure to pollutants, and the presence of acidic substances can accelerate the formation of copper carbonate. Outdoor exposure and the passage of time also play a significant role in the creation of this distinctive green layer.

Why Copper Turns Black?

Copper can also take on a blackened appearance due to the formation of copper sulfide compounds. This blackening process is often observed when copper comes into contact with sulfur-containing substances, such as certain chemicals, gases, or even fingerprints.

Factors Contributing to Blackening

The presence of sulfur compounds in the environment is the primary factor behind copper blackening. Sulfur can originate from various sources, including industrial pollution, vehicle emissions, and even certain cleaning agents. When copper reacts with sulfur, it forms a dark layer of copper sulfide.

Solutions for Green Patina

If you prefer to prevent the development of green patina on your copper items, various solutions are available. Applying protective coatings or using anti-corrosion treatments can slow down the patina process. Regular cleaning and keeping copper objects dry also contribute to prevention.

Preventing Green Patina

To prevent green patina, it's essential to minimize exposure to moisture and airborne pollutants. Storing copper items in controlled environments or using protective coverings can effectively slow down the formation of copper carbonate.

Solutions for Blackening

Addressing blackening involves removing the copper sulfide layer. Mild abrasive cleaners, specialized copper cleaners, or natural cleaning agents like lemon juice and baking soda can help remove the black tarnish. However, prevention is the best approach, as removing blackening without damaging the copper's surface can be challenging.

Preventing Blackening

Preventing blackening requires minimizing exposure to sulfur sources. Store copper items away from areas with high sulfur content, and avoid contact with sulfur-emitting materials. Regular cleaning and gentle handling can also prevent the formation of copper sulfide compounds.

Preserving the Original Appearance

If you wish to maintain the original appearance of your copper items, regular cleaning with gentle methods is essential. Avoid using harsh abrasives that could scratch the surface. Applying a protective wax coating can also help preserve the copper's shine and prevent color changes.

Embracing the Natural Patina

Alternatively, you can choose to embrace the natural evolution of copper's color. The development of patina adds character and uniqueness to objects, contributing to a sense of history and artistry.

Conclusion

The intriguing color changes that copper undergoes, from green to black, add depth to its allure. Understanding the factors behind these transformations and implementing effective solutions can help you preserve or enhance the appearance of your copper CNC machining parts. Whether you choose to prevent, address, or embrace the color changes, the versatility and charm of copper remain timeless.

Frequently Asked Questions

Can I reverse green patina formation?

Reversing green patina is challenging; prevention and maintenance are more effective approaches.

Can I remove black tarnish without damaging the copper?

Removing black tarnish requires caution. Using mild cleaners and gentle methods can help, but prevention is key.

Does copper color change affect its quality?

No, the color changes are primarily superficial and do not significantly affect copper's structural properties.

Can I accelerate patina formation for artistic purposes?

Yes, artists often use controlled environments and chemical treatments to expedite patina formation for creative effects.

Is patina formation on copper harmful?

Patina can actually protect copper from further corrosion, enhancing its durability.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!