15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

143 |

Published by VMT at Mar 04 2024

143 |

Published by VMT at Mar 04 2024

Factors Influencing Lead Time for CNC Machined Parts

In the realm of CNC machined parts manufacturing, the lead time for these components is influenced by a myriad of factors. The accuracy of lead times is crucial for CNC machining factories and customers with custom CNC machining requirements, directly impacting production plan execution, cost control, and the enhancement of customer satisfaction. This article explores various perspectives on the influencing factors of lead time for CNC machined parts, aiming to provide valuable insights for CNC machining factories and customers.

I. Order Volume and Production Capacity

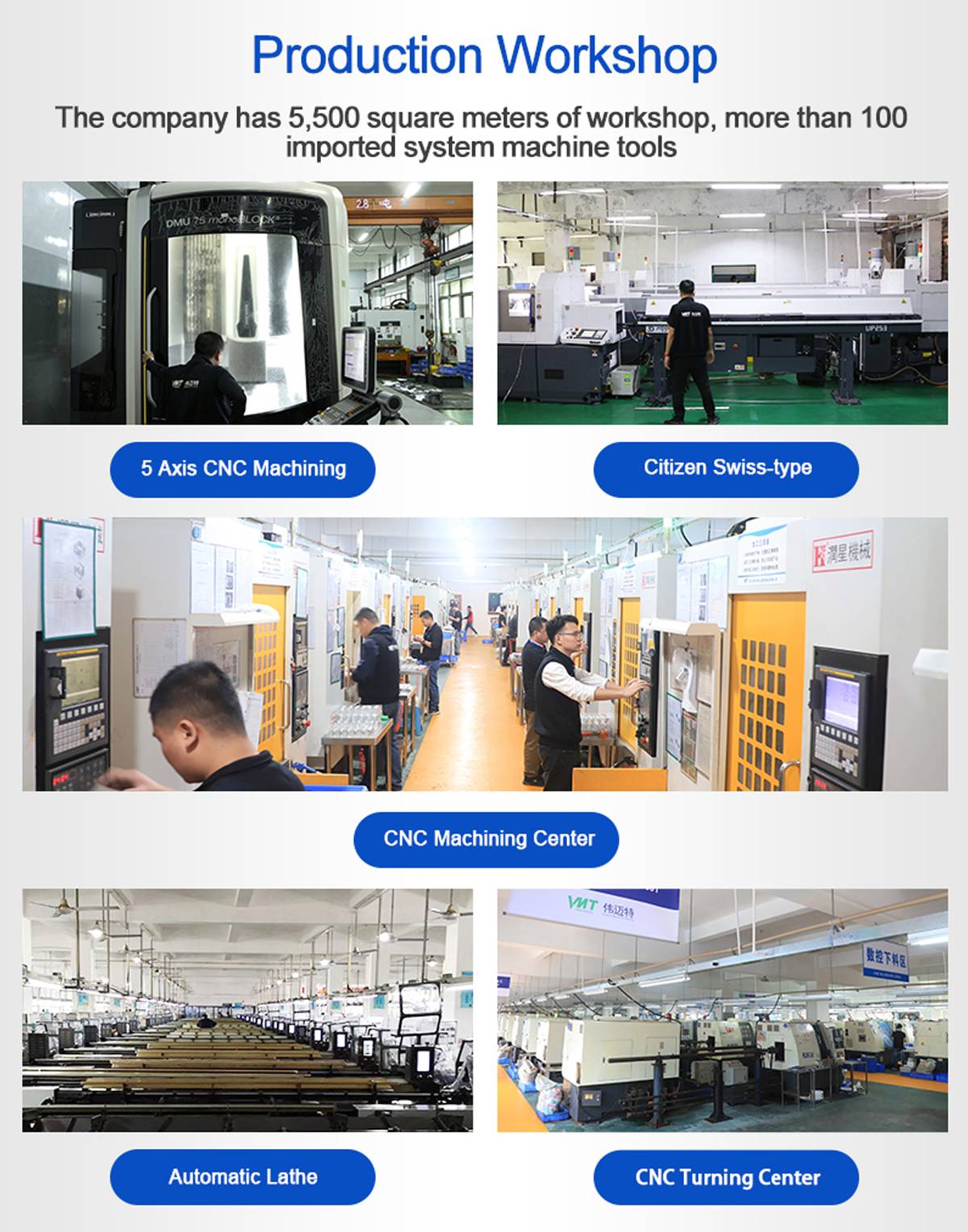

The production capacity of CNC machining factories is a key determinant of lead time. When the order volume exceeds the factory's production capacity, it inevitably leads to an extended lead time. Therefore, before accepting orders, factories should conduct a reasonable assessment of their production capacity to ensure timely product delivery. Additionally, factors such as the condition of production equipment, the number and skill level of technical personnel also impact production capacity, consequently affecting lead time.

The manufacturing of CNC machined parts is contingent on the support of raw materials. The supply, quality, and pricing of raw materials can impact lead time. Issues such as insufficient supply, quality problems, or price fluctuations from raw material suppliers can hinder production, leading to an extended lead time. Hence, CNC machining factories should establish stable partnerships with suppliers to ensure a consistent supply of raw materials.

III. Production Process and Management Level

The optimization of the production process and the level of management directly influence the lead time for CNC machined parts. An efficient production process reduces production steps, enhances efficiency, and consequently shortens lead time. The level of management is reflected in aspects such as the formulation, execution, and monitoring of production plans. A scientifically rational production plan ensures orderly production, avoiding production delays and extended lead times.

IV. Technical Difficulty and Complexity

The technical difficulty and complexity of CNC machined parts also influence lead time. Parts with high technical requirements and complex structures may require more technical resources and time for machining. This could lead to an extended production cycle and subsequently affect the accuracy of lead times. Therefore, factories should thoroughly assess the technical difficulty and complexity of parts before accepting orders, ensuring they possess the corresponding machining capabilities.

V. Quality Control Requirements

Quality control is an integral part of the manufacturing process for CNC machined parts. Strict quality control requirements ensure stable and reliable product quality but may increase production time and costs, influencing lead time. For instance, parts requiring multiple machining processes and inspections may experience a prolonged production cycle. Therefore, factories should consider customer requirements and production realities when formulating quality control requirements, ensuring a balance between quality and minimized production cycles.

VI. External Factors and Force Majeure

In addition to the aforementioned factors, external factors and force majeure can also impact the lead time for CNC machined parts. Natural disasters, policy adjustments, market changes, and other unforeseeable events may disrupt production or lead to delays in lead times. While these factors are challenging to predict and control, factories should be prepared to address potential lead time delays by devising contingency plans, strengthening market research, and other measures.

In conclusion, lead time for CNC machined parts is influenced by a multitude of factors. CNC machining factories should comprehensively consider these factors, formulate scientifically rational production plans and quality control requirements, enhance communication and coordination with suppliers and customers, and improve lead time accuracy and customer satisfaction. Additionally, factories should stay attuned to market changes and evolving customer demands, continually optimizing production processes and management levels to enhance competitiveness and adaptability.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!