15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

109 |

Published by VMT at Mar 05 2024

109 |

Published by VMT at Mar 05 2024

Predicting Lead Time for CNC Machined Parts: Strategies and Considerations

In the realm of CNC machined parts manufacturing, accurately predicting lead time is a crucial task. Precise lead time predictions assist CNC machining factories in effectively managing production schedules, meeting customized customer demands, and enhancing operational efficiency and customer satisfaction. This article explores how to predict lead time for CNC machined parts, providing valuable insights for CNC machining factories and customers.

I. Understand the Production Process of CNC Machined Parts

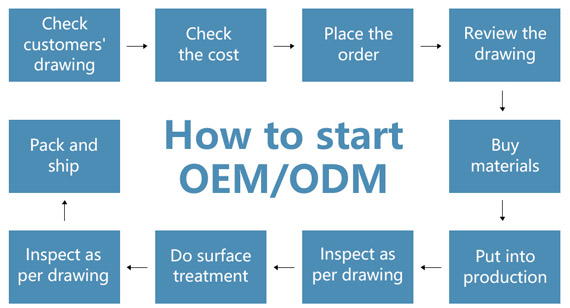

To predict lead time for CNC machined parts, a profound understanding of the production process is essential. This includes comprehending various stages such as order reception, raw material preparation, process planning, part machining, quality inspection, and final delivery. The time and workload required for each stage influence the ultimate lead time.

II. Consider Key Factors Influencing Lead Time

When predicting lead time, various influencing factors must be comprehensively considered. These factors include:

Order Complexity: More complex parts may require additional time and processing steps.

Equipment Condition: The performance, availability, and maintenance of equipment impact production progress.

Raw Material Supply: The quality and stability of raw material supply directly affect production cycles.

Production Planning: The rationality of the factory's production plan and its capacity to meet order demands.

Quality Control: Stringent quality control requirements may extend inspection time and steps.

III. Establish a Lead Time Prediction Model

To achieve more accurate lead time predictions, establishing a lead time prediction model is crucial. This model should integrate various influencing factors, adjusting and optimizing based on historical data and experience. Time series analysis, regression analysis, and machine learning methods can be employed to construct the model.

IV. Real-Time Updates and Adjustments

Lead time prediction is an ongoing task that requires real-time updates and adjustments. As production progresses and actual conditions change, prediction results may alter. Therefore, CNC machining factories need to establish effective feedback mechanisms, collect and analyze production data promptly, and adjust prediction results accordingly.

V. Enhance Communication and Coordination with Other Departments

Predicting lead time for CNC machined parts is not solely the responsibility of the production department. Close communication and coordination with other departments such as sales, procurement, and quality are essential. Regular meetings, information sharing, and collaborative production planning ensure better cooperation, guaranteeing the accuracy and feasibility of lead time predictions.

VI. Utilize Advanced Technology and Tools to Improve Prediction Capability

With the continuous development of information technology and artificial intelligence, CNC machining factories can leverage advanced technologies to enhance lead time prediction capabilities. Implementing IoT technology for real-time monitoring of production equipment, optimizing prediction models with big data and machine learning, and improving data processing and storage capabilities through cloud computing are some examples.

VII. Case Analysis and Practical Implementation

Taking a specific CNC machining factory as an example, the factory considered factors like order complexity, equipment condition, and raw material supply to establish a lead time prediction model. Simultaneously, enhanced communication with other departments, coupled with real-time monitoring and data analysis using IoT and big data technologies, contributed to increased lead time prediction accuracy and customer satisfaction.

VIII. Conclusion and Outlook

Predicting lead time for CNC machined parts is a complex and vital task. CNC machining factories need an in-depth understanding of the production process, consideration of various influencing factors, the establishment of effective lead time prediction models, and continuous updates and adjustments based on real-time data. Strengthening communication with other departments and utilizing advanced technologies are indispensable. In the future, with the continual advancement of CNC machining technology and information technology, lead time prediction will become more precise and efficient. CNC machining factories need to innovate continually and improve to meet growing customer demands and enhance their competitiveness.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!