15 years one-stop China custom CNC machining parts factory

217 |

Published by VMT at Sep 19 2023

217 |

Published by VMT at Sep 19 2023

What is Powder Coated Stainless Steel/Steel?

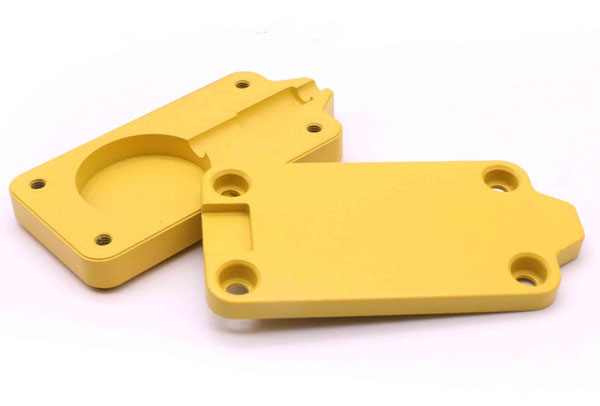

Powder coating stainless steel or steel is a surface treatment method that involves the even application of powder coating onto the surface of stainless steel or ordinary steel (typically carbon steel). Subsequently, through a baking or curing process, the powder coating is transformed into a robust protective layer. This method aims to provide corrosion resistance, aesthetics, and protection.

Can Stainless Steel/Steel be Powder Coated?

Yes, both stainless steel and regular carbon steel can be powder coated. Powder coating is a versatile surface finishing process that can be applied to a variety of metals, including stainless steel, carbon steel, aluminum, and more. It is a highly effective method for providing a durable and aesthetically appealing finish to metal surfaces.

Here's a brief overview of how powder coating is applied to stainless steel and steel:

Surface Preparation: The steel surface is cleaned and prepared to remove any oil, grease, rust, or other contaminants. This step ensures good adhesion of the powder coating.

Application of Powder: The powder coating material, which is a dry powder composed of finely ground particles of pigment and resin, is electrostatically charged and then sprayed onto the prepped steel surface. The charged particles adhere to the grounded metal surface.

Curing Process: The coated steel is then placed in an oven or heated chamber where the powder particles melt, flow, and chemically bond to form a continuous and durable coating. The curing process typically involves heating the steel to a specific temperature for a set duration.

Cooling and Solidification: After the curing process, the coated steel is allowed to cool and solidify, resulting in a smooth and uniform powder coating finish.

Powder coating offers several advantages, including excellent corrosion resistance, a wide range of color options, high durability, and an environmentally friendly application process. It's commonly used in various industries for decorative and protective finishes on steel and other metal substrates.

Why Choose Stainless Steel/Steel Powder Coating?

Choosing powder coating for stainless steel or regular steel surfaces offers a range of benefits that make it a preferred finishing method in various industries. Here are some compelling reasons to choose stainless steel/steel powder coating:

Corrosion Resistance:

Powder coating provides a robust and durable protective layer that enhances the steel's resistance to corrosion and rust. This is crucial for extending the lifespan of the metal, especially in harsh environments.

Aesthetically Pleasing:

Powder coating offers a smooth and attractive finish to the steel surface. The process provides a wide variety of color options and gloss levels, allowing for customization to match design requirements and enhance visual appeal.

Durable Finish:

The cured powder coating forms a hard finish that is more resistant to chipping, scratching, and fading compared to traditional liquid coatings. It ensures a long-lasting, resilient surface.

Environmental Friendliness:

Powder coating is an eco-friendly finishing method as it produces little to no volatile organic compounds (VOCs) or hazardous air pollutants. It aligns with sustainability goals and complies with environmental regulations.

Cost-Effectiveness:

Powder coating is cost-effective due to its efficiency in material usage, reduced waste, and shorter processing times. It often requires minimal touch-ups or reworks, saving on overall costs.

Uniform Coating Thickness:

Powder coating provides an even coating thickness across the entire surface, ensuring consistent appearance and protection. It eliminates the risk of uneven application, which can occur with traditional liquid coatings.

Resistance to Chemicals and Solvents:

The cured powder coating is highly resistant to various chemicals and solvents, making it suitable for applications where exposure to these substances is expected.

Versatility in Applications:

Powder coating can be applied to a wide range of steel products and components, from automotive parts and appliances to architectural elements and industrial equipment. It is versatile and adaptable to diverse application needs.

Easy Maintenance:

Maintaining powder-coated steel surfaces is simple and often requires only regular cleaning with mild detergents and water. The finish retains its appearance and performance for an extended period with minimal maintenance efforts.

In conclusion, selecting stainless steel/steel powder coating enhances the durability, aesthetics, and protective properties of the metal, making it an excellent choice for a variety of applications across different industries.

Can Plastic be Powder Coated?

Yes, plastic can be powder coated, but the process differs from powder coating metal surfaces. Powder coating plastic involves a unique set of considerations and techniques. Here's an overview of how plastic can be powder coated:

Type of Plastic:

Not all plastics are suitable for powder coating. Thermosetting plastics, which can withstand the high temperatures of the curing process without melting or deforming, are typically used. Common thermosetting plastics include certain types of thermosetting polyester and epoxy-based plastics.

Surface Preparation:

The plastic surface must be properly cleaned and prepared. This involves removing any contaminants, oils, or residues that could interfere with adhesion.

Powder Application:

The powder coating material used for plastic is designed to adhere to the specific type of plastic being coated. The powder is electrostatically charged and sprayed onto the plastic surface. The charged particles are attracted to the grounded plastic substrate.

Curing Process:

The plastic, now coated with the powder, is placed in an oven or heated chamber. The curing process involves heating the plastic to a temperature that allows the powder to melt and bond to the surface without causing damage to the plastic. The exact temperature and duration vary depending on the plastic type and powder coating material.

Cooling and Solidification:

After curing, the plastic is allowed to cool and solidify, resulting in a durable and attractive powder coating finish.

It's important to note that the success of powder coating plastic depends on selecting the appropriate type of plastic, powder coating material, and curing process. Not all plastics are suitable for this method, and it's essential to work with experienced professionals who understand the specific requirements of powder coating plastic.

Powder coating plastic can provide benefits such as improved durability, corrosion resistance (for certain types of plastics), and enhanced aesthetics, making it a viable option for various plastic products and components.

Which Metal Parts are Suitable for Powder Coat Finish?

Powder coating is a versatile and effective finishing method for various metal parts. The suitability of metal parts for a powder coat finish depends on factors such as the type of metal, the application, and the desired outcome. Here are common metals material that are suitable for powder coating:

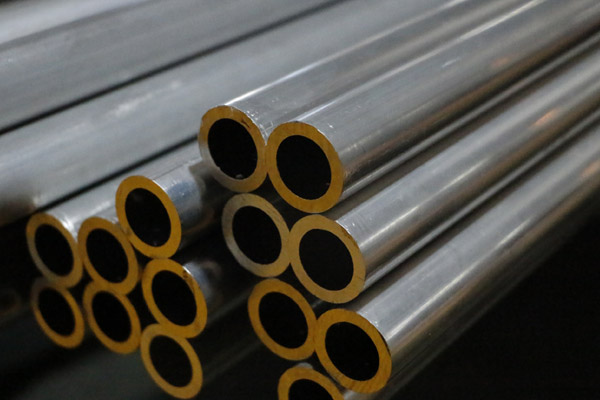

Steel: Carbon steel, including mild steel and stainless steel, is highly suitable for powder coating. It provides excellent adhesion and durability. Powder-coated steel is widely used in industries such as automotive, construction, furniture, and appliances.

Aluminum: Aluminum is another metal that can be effectively powder coated. It offers good corrosion resistance and is commonly used in architectural applications, outdoor equipment, and automotive components.

Cast Iron: Cast iron parts can be powder coated to enhance their appearance and protect them from corrosion. Common applications include ornamental cast iron pieces, cookware, and machinery components.

Brass: While less common than steel or aluminum, brass can also be powder coated. This is often done for decorative purposes or to provide a specific color or finish to brass components.

Copper: Like brass, copper is not as frequently powder coated as other metals, but it is possible to apply a powder coat finish for certain applications where color or protection is desired.

Galvanized Steel: Galvanized steel is sometimes powder coated to enhance its appearance and provide additional corrosion resistance. The powder coat can be applied directly to galvanized steel after proper surface preparation.

Wrought Iron: Wrought iron is commonly powder coated for outdoor furniture, railings, and decorative items. Powder coating helps protect wrought iron from rust and provides various color options.

Magnesium: Magnesium parts used in automotive and aerospace industries can be powder coated for protection and appearance.

Zinc: Zinc surfaces can be powder coated to enhance their appearance and add a layer of protection. This is often seen in architectural applications.

It's important to note that the success of powder coating depends on proper surface preparation, choosing the right powder coating material, and following the correct curing process. Additionally, certain metals may require specific pre-treatment processes to ensure proper adhesion and durability of the powder coat.

In summary, powder coating is a versatile method suitable for a wide range of metal parts, and it offers durability, aesthetics, and protection for various applications. The choice of metal and the specific requirements of the application will determine which metal is the most suitable for powder coating.

Stainless Steel/Steel Parts Powder Coating Process Flow

The powder coating process for stainless steel/steel parts involves several steps to ensure a durable and high-quality finish. Here's an overview of the typical process flow for powder coating metal parts:

Preparation:

Cleaning: The first step is thorough cleaning of the metal parts to remove any contaminants, oils, rust, or other impurities. This cleaning process ensures that the powder adheres to the surface properly.

Surface Pre-Treatment: Depending on the material and specific requirements, surface pre-treatment may be necessary. This can involve processes like chemical etching, phosphating, or sandblasting to improve adhesion and corrosion resistance.

Powder Application:

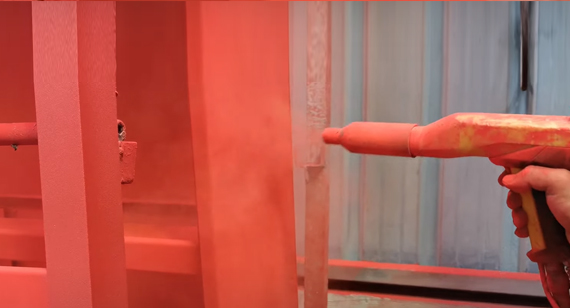

Powder Coating Booth: The cleaned and pre-treated metal parts are placed in a specially designed powder coating booth.

Powder Coating Application: A specialized powder coating gun electrostatically charges the powder particles and sprays them onto the metal parts. The charged particles adhere to the grounded metal surface, creating an even and uniform coat.

Curing:

After the powder coating is applied, the metal parts are moved to a curing oven or chamber. The curing process involves heating the parts to a specific temperature, typically ranging from 350°F to 450°F (177°C to 232°C), for a set duration. During curing, the powder melts and chemically reacts to form a solid and durable coating. The curing time depends on the powder type and thickness.

Cooling:

Once the curing process is complete, the metal parts are allowed to cool down to room temperature. This cooling period helps solidify the powder coating.

The coated parts undergo a thorough inspection to ensure that the coating is uniform, adheres properly, and meets quality standards. Any defects or imperfections are addressed at this stage.

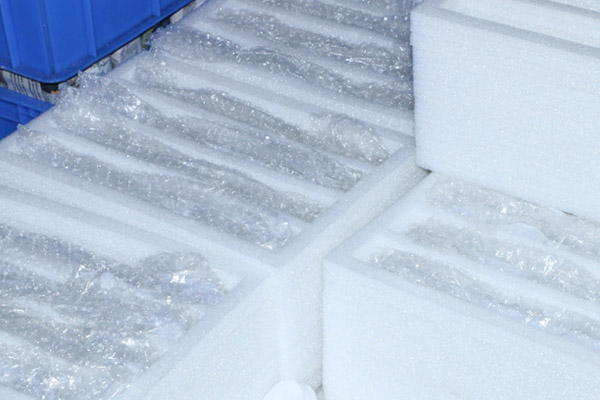

After passing inspection, the finished metal parts are packaged and prepared for shipment to their intended destination.

The powder coating process offers several advantages, including excellent corrosion resistance, a wide range of color options, and a durable finish. It is commonly used in various industries for both functional and decorative purposes.

It's important to note that the specific details of the process can vary depending on factors such as the type of metal, the powder coating material, and the equipment used. Proper surface preparation, precise curing temperatures, and adherence to safety and environmental guidelines are crucial for achieving high-quality powder-coated stainless steel/steel parts.

Stainless Steel/Steel Parts Powder Coating Thickness

The thickness of a powder coating on stainless steel or steel parts can vary depending on several factors, including the application requirements, industry standards, and the specific type of coating being used. However, in general, powder coating thickness is typically measured in terms of mils (1 mil = 0.001 inches) or micrometers (1 micrometer = 0.001 millimeters).

Here are some common guidelines for powder coating thickness:

Standard Thickness: A typical powder coating thickness for most applications falls within the range of 2 to 4 mils (50 to 100 micrometers). This thickness provides a balance between durability and cost-effectiveness.

Functional Coatings: In applications where corrosion resistance, impact resistance, or other functional properties are crucial, a thicker coating may be applied, ranging from 4 to 10 mils (100 to 250 micrometers) or more.

Decorative Coatings: For decorative or architectural applications, a thinner coating of around 1 to 2 mils (25 to 50 micrometers) may be sufficient to achieve the desired appearance without sacrificing the quality of the finish.

Industry Standards: Some industries and applications may have specific standards and requirements for powder coating thickness. It's essential to adhere to these standards to ensure performance and compliance.

Part Geometry: The shape and geometry of the metal part can influence the thickness of the powder coating. Recessed areas and corners may receive a thicker coating to ensure full coverage and protection.

Powder Type: Different types of powder coatings, such as epoxy, polyester, or polyurethane, may have varying recommended thicknesses. It's important to follow the manufacturer's guidelines for the specific powder being used.

Application Method: The method of powder application, such as electrostatic spray, fluidized bed, or dip coating, can also affect the thickness of the coating. Proper application techniques are essential to achieve the desired thickness.

It's important to note that achieving the correct powder coating thickness is critical to the performance and durability of the finish. Too thin a coating may not provide adequate protection, while an excessively thick coating may lead to issues like poor adhesion or surface defects.

Quality control measures, such as regular thickness measurements and adherence to industry standards, can help ensure that the powder coating thickness meets the desired specifications for stainless steel or steel parts.

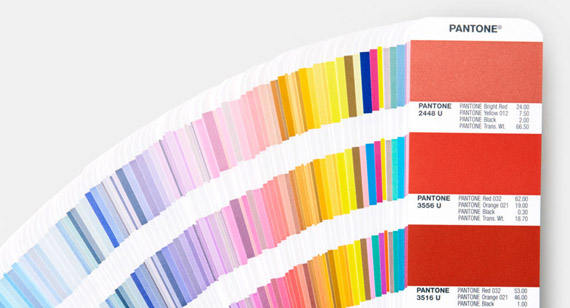

What Colors can be Powder Coated on Stainless Steel/Steel Parts?

Powder coating offers a wide range of color options for stainless steel and steel parts. The available colors are diverse and can be customized to meet specific design and application requirements. Here are some of the common colors that can be powder coated on stainless steel and steel parts:

Standard Colors:

White

Black

Gray

Silver

Red

Blue

Green

Yellow

Brown

Custom colors can be achieved by mixing different powder coating pigments to create unique shades and hues. This allows for a high degree of color customization to match branding or design preferences.

Metallic Finishes:

Powder coatings with metallic effects are available to mimic the appearance of metals like gold, bronze, copper, or aluminum. These finishes can add a luxurious or decorative touch to parts.

Textures and Special Effects:

Powder coatings are not limited to solid colors. They can also create textured or special effects finishes such as hammertone, wrinkle, and sandpaper-like textures.

Clear Coats:

Clear powder coatings are used to protect the natural appearance of stainless steel while providing a durable and transparent protective layer.

Gloss Levels:

The gloss level of a powder coating can be adjusted to achieve different surface finishes, including high gloss, semi-gloss, satin, and matte.

Custom Branding Colors:

Companies often choose powder coating colors that match their branding or corporate identity, allowing for consistency across product lines.

Color Matching:

Powder coating suppliers and manufacturers can provide color matching services to ensure that the chosen color matches a specific sample or swatch.

It's important to note that the availability of colors may vary depending on the specific powder coating manufacturer and the type of powder coating material used. Some manufacturers may offer a comprehensive color catalog, while others can create custom colors upon request.

When selecting a color for powder coating stainless steel or steel parts, it's essential to consider factors such as aesthetics, branding, application environment, and color durability. Powder coating not only provides a vibrant and long-lasting finish but also offers protection against corrosion and wear.

What Effect does Powder Coating have on Stainless Steel/Steel Parts? Size, Accuracy

Powder coating can have several effects on stainless steel and steel parts, including size and accuracy considerations. Here are the primary effects to consider:

Coating Thickness: Powder coating adds a protective layer to the surface of stainless steel or steel parts. The thickness of this coating can vary based on application requirements but is generally measured in mils (thousandths of an inch) or micrometers (microns). The coating thickness should be factored into size and tolerance considerations.

Dimensional Changes: Powder coating can introduce slight dimensional changes to parts due to the added thickness of the coating. While the impact is typically minimal, it's essential to account for this in the design and manufacturing process, especially for parts with tight tolerances.

Surface Smoothness: The quality of the powder coating application can affect the surface smoothness of parts. High-quality powder coating processes produce smooth and even finishes. However, textured or specialty finishes may introduce surface irregularities, which should be considered in design.

Color Uniformity: Powder coating provides an even and uniform color across the entire surface of a part, enhancing its appearance. Variations in color uniformity can be controlled through proper powder coating techniques and quality control measures.

Corrosion Resistance: One of the significant benefits of powder coating is its ability to enhance corrosion resistance. Coated stainless steel or steel parts are better protected against environmental factors, which can extend their lifespan and maintain dimensional stability over time.

Electrical Properties: Powder coating may affect the electrical conductivity of metal parts, particularly if the coating is insulating. For applications where electrical conductivity is essential, special consideration is needed.

Thermal Properties: Powder coating can impact the thermal properties of metal parts, affecting heat transfer or insulation characteristics. This is especially relevant in applications involving heat-sensitive components.

Adherence and Bond Strength: Proper surface preparation and powder coating application are critical to ensure that the coating adheres well to the metal surface. A strong bond between the coating and the metal is essential for durability.

To mitigate potential size and accuracy issues when powder coating stainless steel or steel parts, manufacturers should follow best practices, including:

Precise Surface Preparation: Thoroughly clean and prepare the metal surface to ensure proper adhesion and uniform coating thickness.

Tolerance Consideration: When designing parts, account for the expected coating thickness and its impact on dimensions and tolerances.

Quality Control: Implement quality control measures to inspect and verify the coating thickness, color uniformity, and overall finish quality.

Coating Selection: Choose the appropriate powder coating material, taking into account its properties and how they may affect the part's function.

By addressing these considerations, manufacturers can achieve the desired powder coating results while maintaining the size and accuracy of stainless steel or steel parts.

Advantages and Disadvantages of Stainless Steel/Steel Powder Coating

Stainless steel/steel powder coating offers several advantages and disadvantages, which are important to consider when choosing this surface treatment for metal parts. Here are the key advantages and disadvantages:

Advantages:

Corrosion Resistance: Powder coating provides excellent corrosion protection for stainless steel and steel parts. It forms a durable barrier against moisture, chemicals, and environmental factors, extending the lifespan of the parts.

Aesthetics: Powder coating offers a wide range of color options and finishes, allowing for customization to achieve desired aesthetics. This makes it suitable for decorative and architectural applications.

Durability: Powder coatings are highly durable and resistant to chipping, peeling, fading, and scratching. This makes them ideal for parts exposed to wear and tear.

Environmental Benefits: Powder coating is an eco-friendly process that produces minimal volatile organic compounds (VOCs) and waste. It is considered a more sustainable alternative to traditional wet painting.

Uniform Finish: Powder coating results in a consistent and uniform finish across the entire surface of a part, enhancing its appearance.

Cost-Effective: Powder coating can be cost-effective, especially for large production runs, as it reduces the need for rework and touch-up compared to other coating methods.

Quick Curing: Powder coatings cure rapidly when exposed to heat, which can speed up production processes.

Disadvantages:

Thickness Variation: Achieving precise and consistent coating thickness can be challenging, and variations may occur, affecting tolerances on critical dimensions.

Initial Investment: Setting up a powder coating facility can require a significant initial investment in equipment and infrastructure.

Complex Geometry: Parts with intricate or complex geometries may be challenging to coat evenly, leading to potential coverage issues.

Surface Preparation: Proper surface preparation is crucial for powder coating success. Failing to remove contaminants or prepare the surface adequately can lead to adhesion problems.

Limited Heat Resistance: Powder coatings may not withstand extremely high temperatures, making them unsuitable for parts exposed to extreme heat conditions.

Color Change: While powder coating is durable, prolonged exposure to UV radiation may cause color fading or change in some cases.

Recoating Difficulty: Recoating or refinishing powder-coated parts can be challenging, as removing the existing coating can be labor-intensive.

Electrical Conductivity: Powder coatings are typically insulating, which can affect the electrical conductivity of parts in certain applications.

Overall, stainless steel/steel powder coating is a versatile and effective surface treatment with numerous advantages, particularly in terms of corrosion resistance and aesthetics. However, careful consideration of design, surface preparation, and quality control is essential to address potential disadvantages and ensure successful powder coating applications.

What Surface Effect does Powder Coated Stainless Steel/Steel Parts Exhibit?

Powder-coated stainless steel and steel parts can exhibit various surface effects, depending on the type of powder coating material and the specific application process used. Here are some common surface effects that can be achieved with powder-coated metal parts:

Smooth Finish: A smooth and even surface finish is one of the most common effects of powder coating. It provides a sleek and polished appearance, enhancing the aesthetics of the metal parts.

Textured Finishes: Powder coatings can produce textured surface finishes, such as hammertone, wrinkle, and sandpaper-like textures. These textures can add visual interest and uniqueness to the parts.

Gloss Levels: Powder coatings offer flexibility in gloss levels, allowing for customization of the surface appearance. Options include high gloss, semi-gloss, satin, and matte finishes.

Metallic Effects: Some powder coatings are formulated to create metallic effects that mimic the appearance of metals like gold, bronze, copper, or aluminum. These effects can provide a luxurious or decorative look to the parts.

Clear Coats: Clear powder coatings can be used to protect the natural appearance of stainless steel while providing a transparent and protective layer. This maintains the metal's original finish while adding durability.

Color Uniformity: Powder coating provides consistent and uniform color across the entire surface of the part. This ensures that the color appears uniform without streaks or variations.

Custom Colors: Custom colors can be achieved by mixing different powder coating pigments to create unique shades and hues. This allows for high levels of color customization to match specific design requirements.

Patterned Effects: Special masking techniques and stencils can be used during the powder coating process to create patterned or decorative effects on the surface of the parts.

Two-Tone or Multi-Color Finishes: Powder coating can be used to create two-tone or multi-color finishes on parts, enabling creative and eye-catching designs.

Anti-Graffiti Coatings: Some powder coatings are formulated with anti-graffiti properties, making it easier to remove graffiti without damaging the underlying finish.

The specific surface effect achieved depends on the choice of powder coating material, the application method, and any additional techniques used during the coating process. Designers and manufacturers can work with powder coating specialists to select the most suitable coating and finish to meet their desired aesthetic and functional requirements.

Stainless Steel/Steel Powder Coating vs. Other Surface Treatments: Differences, Finishes, and Cost Comparison

Stainless steel/steel powder coating is one of several surface treatment options available for metal parts. Here's a comparison of powder coating with other common surface treatments, highlighting differences, surface finishes, and cost considerations:

1. Powder Coating:

Process: Powder coating involves electrostatically applying dry powder particles to the metal surface and curing it with heat.

Finishes: Powder coating offers a wide range of finishes, including smooth, textured, metallic, and custom colors.

Durability: It provides excellent corrosion resistance, impact resistance, and UV resistance.

Environmental Impact: Powder coating is environmentally friendly, producing minimal waste and VOCs.

Cost: The cost of powder coating can vary but is generally cost-effective, especially for large production runs.

2. Wet Painting (Liquid Coating):

Process: Wet painting involves applying liquid paint to the metal surface, followed by drying and curing.

Finishes: Wet painting can achieve various finishes, including gloss, matte, and custom colors.

Durability: Durability depends on the type of paint used. Specialized coatings can provide good protection.

Environmental Impact: Wet painting can produce hazardous waste and volatile organic compounds (VOCs).

Cost: Costs can vary, with high-quality paints and specialized coatings being more expensive.

3. Anodizing (For Aluminum):

Process: Anodizing is an electrochemical process used primarily for aluminum. It forms a protective oxide layer on the metal's surface.

Finishes: Anodizing provides matte, satin, or bright finishes, depending on the process and dye used.

Durability: It offers excellent corrosion resistance and durability for aluminum parts.

Environmental Impact: Anodizing is more environmentally friendly than some other processes.

Cost: Costs can vary, with anodizing generally being cost-effective for aluminum parts.

4. Galvanizing:

Process: Galvanizing involves applying a layer of zinc to steel or iron to provide corrosion protection.

Finishes: Galvanizing typically results in a shiny or matte gray finish.

Durability: It offers excellent corrosion resistance but may not be suitable for decorative applications.

Environmental Impact: Galvanizing can produce emissions and waste, but it's recyclable.

Cost: The cost of galvanizing is generally moderate.

5. Plating (Chrome, Nickel, etc.):

Process: Plating involves depositing a thin layer of metal (e.g., chrome, nickel) onto the surface of the part.

Finishes: Plating provides shiny and reflective finishes but may require post-treatment for coloring.

Durability: Plating enhances corrosion resistance and can provide decorative effects.

Environmental Impact: Electroplating can have environmental concerns due to chemicals used.

Cost: Costs can vary widely based on the type of plating and part size.

6. Ceramic Coating:

Process: Ceramic coating involves applying a heat-resistant ceramic layer to metal parts.

Finishes: It provides a high-temperature-resistant finish and is often used in automotive and industrial applications.

Durability: Ceramic coatings offer excellent heat resistance and protection against oxidation.

Environmental Impact: Ceramic coatings are generally environmentally friendly.

Cost: Costs can vary based on the type of ceramic coating and application complexity.

The choice between these surface treatments depends on factors such as the metal type, intended application, aesthetics, environmental considerations, and budget. Powder coating is a versatile option known for its durability, wide range of finishes, and cost-effectiveness, making it a preferred choice for many applications. However, each treatment has its unique advantages and limitations, and selecting the right one requires careful consideration of specific project requirements.

Powder Coated Stainless Steel/Steel Parts Applications

Powder-coated stainless steel and steel parts find applications in various industries and settings due to their durability, corrosion resistance, and customizable aesthetics. Here are some common applications of these powder-coated parts:

Architectural and Building Construction:

Handrails and balustrades

Exterior and interior architectural elements

Fencing and gates

Window and door frames

Building facades

Automotive Industry:

Automotive body parts and components

Wheels and rims

Exhaust systems

Engine parts

Suspension components

Furniture and Decorative Items:

Outdoor and indoor furniture

Lighting fixtures

Shelving and storage units

Garden and patio decor

Sculptures and art installations

Industrial Equipment:

Machinery components

Conveyor systems

Metal cabinets and enclosures

Material handling equipment

Safety barriers and bollards

Appliances and Electronics:

Household appliances (e.g., ovens, refrigerators)

Computer server racks

Electronic enclosures

Commercial kitchen equipment

Vending machines

Recreational and Sports Equipment:

Playground equipment

Fitness machines and equipment

Sporting goods (e.g., golf clubs, ski poles)

Camping gear and accessories

Marine and Offshore Applications:

Boat and yacht components

Marine handrails and railings

Offshore platform structures

Underwater equipment

Medical and Healthcare Devices:

Medical equipment frames and housings

Hospital furniture and fixtures

Dental equipment

Laboratory apparatus

Agriculture and Farming:

Agricultural machinery and equipment

Farm gates and fencing

Livestock handling systems

Irrigation components

Retail Displays and Fixtures:

Store shelving and displays

Point-of-sale (POS) equipment

Merchandising fixtures

Commercial signage

Aviation and Aerospace:

Aircraft components and interiors

Ground support equipment

Aerospace hardware and fittings

Oil and Gas Industry:

Oil rig components

Pipeline supports

Drilling equipment

Electrical and Electronics Enclosures:

Control panels

Junction boxes

Server cabinets

Food Processing and Packaging:

Conveyor systems

Food processing equipment

Packaging machinery

These are just some examples of the diverse applications of powder-coated stainless steel and steel parts. The versatility and protective qualities of powder coating make it a popular choice for enhancing both the functionality and aesthetics of various products and structures across multiple industries.

Powder Coated Stainless Steel/Steel Parts Problem Points and Considerations

When dealing with powder-coated stainless steel or steel parts, there are specific problem points and considerations to take into account to ensure the best results and longevity of the coating. Here are some critical points and considerations:

Surface Preparation:

Ensure thorough cleaning and preparation of the surface to remove any oil, dirt, or contaminants that may hinder adhesion or cause defects in the powder coating.

Surface Quality:

Address any surface imperfections, scratches, or dents before applying the powder coating to achieve a smooth and uniform finish.

Proper Coating Thickness:

Apply the powder coating with the appropriate thickness to ensure durability and resistance to wear, chemicals, and corrosion. Inadequate or excessive coating thickness can lead to performance issues.

Curing Process:

Follow the manufacturer's recommendations for the curing process, including time and temperature, to achieve the desired properties of the powder coating and maximize its adhesion and durability.

Temperature and Humidity Control:

Maintain appropriate temperature and humidity levels in the curing oven to avoid issues like orange peel, dry spray, or improper flow and leveling of the powder.

Storage and Handling:

Store powder coatings in a cool, dry place to prevent clumping and maintain their integrity. Handle powders with clean, dry hands and equipment to avoid contamination.

Masking and Protection:

Use proper masking techniques to protect areas that should not be coated, ensuring a clean and precise finish.

Electrostatic Application:

Optimize the electrostatic application process to ensure even coverage and minimize Faraday cage effects, especially on complex or recessed surfaces.

Inspection and Quality Control:

Implement thorough inspection processes to identify any defects, inconsistencies, or imperfections in the coating. Address and rectify issues promptly.

UV Resistance:

Consider the exposure to UV radiation in the application environment and select powder coatings with suitable UV resistance to prevent fading or degradation over time.

Adhesion and Bonding:

Promote strong adhesion of the powder coating by evaluating surface treatments like sandblasting or chemical etching that enhance bonding with the substrate.

Post-Curing:

Conduct a post-cure process, if necessary, to further enhance the properties of the powder coating, especially for applications that demand exceptional durability and resistance.

Cleaning and Maintenance:

Educate end-users on appropriate cleaning and maintenance procedures to extend the lifespan and appearance of the powder-coated parts.

Environmental Considerations:

Comply with environmental regulations and guidelines concerning the handling, disposal, and recycling of powder coatings and related materials.

By focusing on these problem points and considerations, manufacturers and applicators can ensure a successful powder coating process, resulting in high-quality, durable, and aesthetically pleasing powder-coated stainless steel or steel parts.

Conclusion

Do you know how to choose the right finish for your project? VMT has 15 years of experience in surface treatment experts to choose the appropriate surface treatment for you to improve the surface texture and performance of powder coating stainless steel CNC machined parts.

Learn about the powder coating surface treatment process, benefits and applications in this article. If you want to know more about powder coating surface treatment, please contact us immediately. VMT can provide a wide range of CNC machining and manufacturing capabilities and surface treatment services for stainless steel, aluminum, titanium, copper and other materials. Our team of professional engineers can select the appropriate surface treatment for you to meet all your powder coating stainless steel CNC machined parts production needs. , get the best, competitive price. Why not give VMT a try and contact us now to get a quote.

Powder Coated Stainless Steel/Steel Parts FAQs

ertainly! Here are some frequently asked questions (FAQs) regarding powder-coated stainless steel/steel parts:

How long does powder coating last on steel?

Powder coating on steel can last anywhere from 15 to 20 years or more, depending on the quality of the coating, the environment, and the application. Proper surface preparation and curing significantly contribute to its longevity.

Will steel rust after being powder coated?

Properly applied powder coating provides excellent corrosion resistance. However, if the coating is damaged or chipped, exposing the steel, it can be susceptible to rusting over time. Regular maintenance and repair of any damage are essential to prevent rusting.

Can powder-coated steel be repainted?

Yes, powder-coated steel can be repainted. The old coating needs to be stripped and the surface properly prepared before applying a new coat of powder. It's important to follow appropriate procedures for adhesion and durability.

Is powder coating environmentally friendly?

Yes, powder coating is considered environmentally friendly. It produces little to no volatile organic compounds (VOCs), and oversprayed powder can be collected and reused, minimizing waste.

Can powder coating be applied to intricate parts?

Yes, powder coating can be applied to intricate and complex parts using specialized techniques such as electrostatic guns and powder booths, ensuring even coverage on complex surfaces.

Can powder coating be applied to both stainless steel and regular steel?

Yes, powder coating is suitable for both stainless steel and regular steel. However, proper surface preparation is crucial to achieve good adhesion and durability, particularly for stainless steel.

Is powder coating scratch-resistant?

Powder coating provides good scratch resistance, but it's not entirely scratch-proof. The degree of resistance depends on the type of powder used and the coating thickness.

Can powder-coated steel withstand extreme temperatures?

Powder coating can withstand a wide range of temperatures, making it suitable for both indoor and outdoor applications. Special formulations are available for high-temperature environments.

Can powder coating be applied to small parts effectively?

Yes, powder coating can be applied to small parts effectively using appropriate equipment and techniques to ensure uniform and precise coating application.

Can powder-coated steel be used for food-related applications?

Yes, powder-coated steel can be used for certain food-related applications, provided the powder coating is FDA-approved and certified as food-safe.

These FAQs address common inquiries about powder-coated stainless steel and steel parts, covering aspects related to durability, appearance, environmental impact, and applicability in different scenarios.