15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

155 |

Published by VMT at Oct 10 2023

155 |

Published by VMT at Oct 10 2023

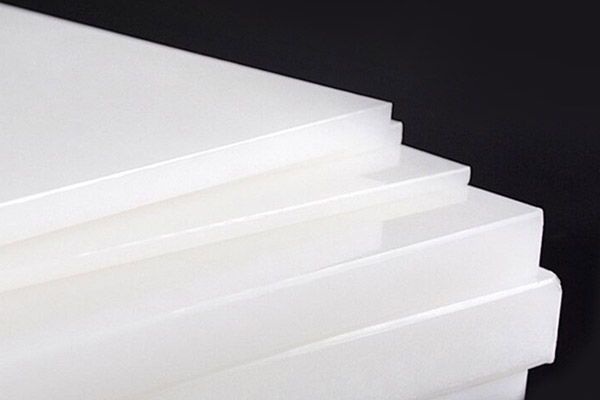

There are many methods to reduce product costs through design, with one of the most effective being the selection of the most suitable materials, CNC machining manufacturing processes, and assembly methods during product design. One highly impactful approach is to replace steel with plastic.

Why Can Replacing Metal with Plastic Reduce Costs?

Replacing metal with plastic means using high-performance engineering plastic components instead of traditional metal parts without compromising product quality and performance. This simplifies product structures, reduces production costs, and achieves lightweighting.

From a purely cost perspective, substituting plastic for metal typically reduces product costs by 25% to 50% due to the following reasons:

1. Complex Shape and Design Freedom:

Injection molding can produce plastic parts with far more complex shapes than metal. Plastic parts can have intricate curved surfaces, internal structures, and various features like thin walls, holes, undercuts, threads, bosses, ribs, and tabs, which are challenging or expensive to achieve with metal manufacturing processes. This allows plastic parts to consolidate surrounding metal or other components, reducing material and CNC machining costs.

Several metal CNC parts are removed, thus saving raw material costs and CNC machining costs for metal parts.

The product structure is simple, reducing and eliminating fasteners required for assembly.

Avoid complex assembly processes such as welding and riveting, shorten assembly time, and reduce component assembly costs.

2. Lower Assembly Costs:

Plastic parts often use fastening methods like snaps, clips, and ultrasonic welding, reducing the need for mechanical fasteners commonly used with metal parts, such as welding, riveting, or threaded fasteners. This simplifies assembly, shortens assembly time, and lowers component assembly costs.

3. Avoiding Secondary Machining:

Many metal CNC manufacturing processes, such as sand casting and die casting, often require secondary processing like CNC machining, painting, and plating to meet quality, appearance, and corrosion resistance requirements. Plastic parts typically have higher dimensional accuracy, better surface quality, and a variety of color options, reducing or eliminating the need for secondary processing and associated costs.

4. High Production Efficiency and Low Machining Costs:

Even complex plastic shapes are relatively easy to manufacture once the injection mold is made. Injection molding can produce the required parts in a single step, resulting in high production efficiency and low processing costs. Furthermore, multi-cavity molds can produce multiple identical parts in a single injection cycle, further increasing production efficiency.

5. Long Mold Life:

Compared to metal die-casting molds, plastic injection molds have a longer service life. Proper mold material selection and design can extend the life of injection molds to over 500,000 to 1 million cycles or more, reducing mold manufacturing, maintenance, and repair costs.

6. Lower Plastic Material Costs:

Plastic materials, being a byproduct of the petroleum industry, are readily available and cost less per unit volume compared to metal materials of similar volume.

7. Recyclability:

Plastic parts often generate minimal waste during production, and any excess material can be reground and reused. This minimizes plastic material costs.

8. Reduced Packaging and Transportation Costs:

Plastics are lighter than metals, resulting in reduced packaging material costs and lower transportation expenses due to lower weight.

9. Lower Energy Consumption and Operating Costs:

Plastic's lower density means products consume less energy during operation, leading to reduced operating costs. For example, lighter vehicles have lower fuel consumption.

In addition to cost advantages, plastics offer other benefits:

Plastic has a low density, which provides functionality for lightweighting the product. The density of plastic materials is generally between 0.9~1.8kg/dm3; while the density of metal is generally between 3~8 kg/dm3.

Lightweighting: Plastic materials contribute to lightweighting, enhancing product functionality.

Corrosion Resistance: Plastics are suitable for various chemical and corrosive environments, unlike metals that are susceptible to corrosion.

Mechanical Properties: High-performance plastics can even surpass metals in mechanical properties like tensile strength.

Lubrication-Free: Some plastics, such as POM, exhibit excellent wear resistance, reducing the need for expensive lubricants, especially in food applications.

Energy Efficiency: Plastics consume less energy during operation, resulting in faster equipment in many cases.

Acoustic Insulation: Plastics can be used for sound insulation due to their non-conductive nature.

Electrical Insulation: Plastics are excellent insulators, making them suitable for electrical applications.

Low Thermal Conductivity: Plastics feel comfortable to the touch due to their low thermal conductivity.

In summary, replacing metal with plastic offers significant cost advantages while providing a wide range of functional benefits.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!