15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

274 |

Published by VMT at Jan 28 2025 | Reading Time:About 2 minutes

274 |

Published by VMT at Jan 28 2025 | Reading Time:About 2 minutes

When it comes to selecting materials for engineering, manufacturing, or CNC machining, understanding the difference between stiffness and strength is crucial. These two properties are often confused but serve very different functions. Both are key to ensuring the performance and durability of parts, but knowing when to prioritize one over the other can impact the design process. In this article, we’ll explore the distinctions between stiffness and strength, how they influence material selection, and why getting the balance right is essential for optimal performance in CNC machining and beyond.

At first glance, stiffness and strength might seem like similar concepts. However, they are fundamentally different characteristics of a material that play crucial roles in its overall performance. Strength refers to a material's ability to withstand an applied force without breaking, while stiffness describes how much a material resists deformation under that force. Understanding both can help determine how materials will behave in different environments or applications, ensuring that the right choice is made for each specific requirement.

Strength is the ability of a material to withstand an external force without failing. A material that is considered strong can endure high stress before it begins to deform or break. However, this doesn't necessarily mean the material won't bend or stretch under pressure; it simply means it can endure more force without failing.

Types of Strength

1. Tensile Strength

Tensile strength refers to a material’s ability to resist pulling or stretching forces. There are three main types of tensile strength:

2. Impact Strength

Impact strength is a measure of how well a material can absorb energy during an impact. This is particularly important for materials that need to withstand sudden forces, like those found in automotive parts or structural components.

3. Compressive Strength

Compressive strength measures how well a material resists being squashed or compressed. It’s particularly relevant for materials used in construction, such as concrete or metals like stainless steel and titanium.

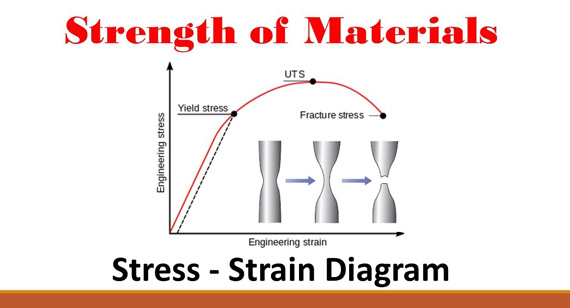

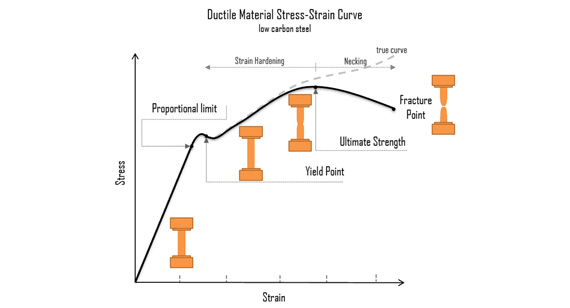

Yield Strength vs. Ultimate Strength

Yield strength and ultimate strength are often confused, but they refer to different points in a material’s stress-strain curve. Yield strength is where the material begins to plastically deform, while ultimate tensile strength is the maximum stress the material can endure before breaking. Both are essential in selecting materials for CNC machining and other applications.

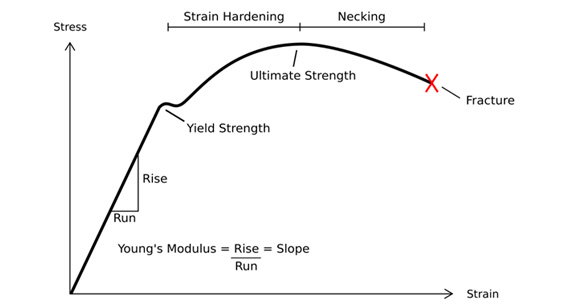

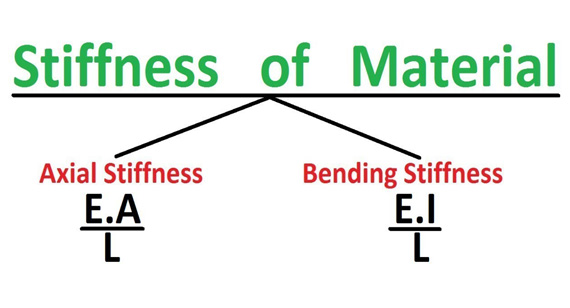

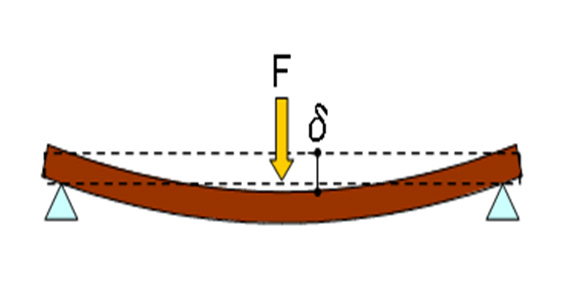

Material stiffness refers to how much a material resists deformation under an applied force. A material with high stiffness will deform less when stress is applied. It is commonly characterized by the modulus of elasticity, which measures the ratio of stress to strain in the elastic (non-deforming) region of a material.

Although stiffness and strength are related, they are distinct properties. A material can be stiff but not strong (like glass), or strong but not stiff (like rubber). The key difference is that stiffness measures how much a material bends or deforms, while strength measures how much it can handle before breaking. In many cases, materials with high strength are also stiff, but this is not always the case. Therefore, engineers must consider both properties when designing parts for CNC machining or other manufacturing processes.

The primary difference between strength and stiffness lies in how a material reacts under stress. Strength is about how much load a material can bear without breaking or failing, whereas stiffness is about how much it resists deformation. For example, a strong material like steel can bear a lot of weight before breaking, but it is also very stiff, meaning it won’t bend easily under a load. On the other hand, a material like rubber may be strong enough to withstand a certain amount of force, but it will deform significantly under even small stresses.

When designing for strength and stiffness, several key practices can help ensure the material chosen will meet both the functional and structural needs of the final product.

Calculate the Expected Stress for Each Material

Understanding the specific forces that will act on the material in its application is critical. Designers must calculate the expected stress and choose materials with the appropriate strength and stiffness to handle those forces.

Test a Range of Materials Before Selecting

It’s always advisable to test different materials under real-world conditions before making a final choice. Different materials behave differently when subjected to stress and strain, and testing ensures the best material is selected for the job.

Identify Important Factors When Starting a Design

Designers must determine the key factors, such as load conditions, environmental factors (temperature, moisture, etc.), and the desired life cycle of the product. This will help guide decisions about material selection and the required balance of strength and stiffness.

Confirm the Functionality of the Design Before Prototyping

Ensuring the design is functional before moving to the prototyping stage can help avoid wasting time and resources. Using simulations and analysis tools can help verify the strength and stiffness of the material before committing to CNC machining or other manufacturing processes.

The distinction between stiffness and strength is crucial in material selection for manufacturing, particularly when designing for CNC machining. While strength determines how much force a material can handle before failure, stiffness dictates how much it resists deformation under stress. Understanding both properties allows engineers and manufacturers to make better choices for materials that will perform optimally in their applications.

Is strength the same as stiffness?

No, strength and stiffness are different properties. Strength refers to a material's ability to withstand stress without breaking, while stiffness refers to how much a material resists deformation under stress.

What is the difference between yield strength and stiffness?

Yield strength is the point at which a material starts to deform plastically, while stiffness refers to a material’s resistance to deformation under load.

How do you calculate stiffness strength?

Stiffness can be calculated using the modulus of elasticity, which is the ratio of stress to strain in the elastic region of a material.

Is stiffness the same as toughness?

No, stiffness refers to a material’s resistance to deformation, while toughness measures how much energy a material can absorb before breaking.

What is the difference between stiff and strong materials?

Stiff materials resist deformation, while strong materials can bear high forces without breaking. Some materials may be stiff but not strong, or strong but not stiff.

How can something be strong but brittle?

A material can be strong but brittle if it can withstand a lot of stress without breaking, but it fractures easily under sudden or sharp impacts.

Is stiffness the same as tensile strength?

No, tensile strength is the ability to resist breaking under tension, while stiffness is the ability to resist deformation under load.

Why is steel so stiff?

Steel is stiff due to its high modulus of elasticity, meaning it resists deformation when subjected to stress.

What is the difference between toughness and firmness?

Toughness measures how much energy a material can absorb before fracturing, while firmness refers to a material’s resistance to deformation.

Is the hardness of a material equal to its strength?

No, hardness refers to a material’s ability to resist indentation or scratching, while strength refers to its ability to resist breaking under stress.

What is the formula for stiffness?

Stiffness can be calculated using the formula  , where F is the force applied, and Δ

, where F is the force applied, and Δ

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!