15 years one-stop China custom CNC machining parts factory

148 |

Published by VMT at Jan 27 2025 | Reading Time:About 2 minutes

148 |

Published by VMT at Jan 27 2025 | Reading Time:About 2 minutes

Imagine you’re in the middle of a CNC machining project, and suddenly, a tap breaks off in the workpiece. This is a nightmare scenario for machinists, but it doesn’t have to bring your project to a halt. Taps are essential for creating internal threads, but they can sometimes break, causing significant delays and frustration. Understanding how to remove broken taps quickly and efficiently can save time and prevent costly mistakes. In this article, we’ll explore the main causes of tap breakage, the tools and techniques available to remove them, and best practices to avoid future breakages.

Removing a broken tap requires the right tools and techniques, such as using tap extractors, drilling, or even utilizing EDM machines. It's critical to understand why taps break and how to prevent it from happening. This guide covers the most effective methods and tips for removing broken taps, making it essential reading for CNC machining professionals.

Now that we’ve discussed the importance of removing broken taps, let’s explore the key reasons why taps break in the first place. Understanding the causes of tap failure can help you prevent these issues in the future and ensure smoother machining operations.

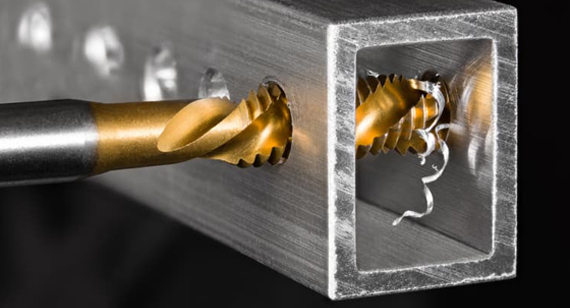

Taps are cutting tools used in machining processes to create internal threads, allowing bolts, screws, and other fasteners to fit securely into a hole. They play a critical role in manufacturing, especially in CNC machining, where precision is paramount. Tapping involves rotating the tap into the material, which creates the desired thread profile. While taps are durable tools, they can break under certain conditions, leading to costly delays and damage to the workpiece.

Tap breakage can be a frustrating and costly issue in CNC machining. Several factors contribute to the failure of taps, and understanding these reasons can help prevent them from occurring in the future. Let’s break down the primary causes of tap breakage:

1. Poor Tap Quality

One of the most common reasons taps break is poor-quality material or craftsmanship. Low-quality taps may be more prone to wear, breakage, or failure under the stress of repeated use. Opting for high-quality taps from reputable manufacturers can help reduce the likelihood of tap failure.

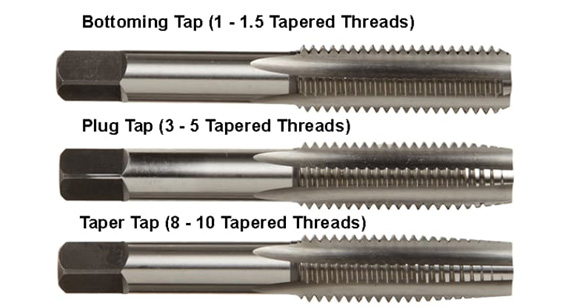

2. Improper Tap Selection

Choosing the wrong type of tap for the material or application can significantly increase the risk of breakage. For example, using a general-purpose tap for hard metals or a coarse-thread tap for fine threads can cause the tool to wear out more quickly or even snap.

3. Incompatibility with the Raw Material

Some materials, such as certain alloys or hardened metals, can be difficult to tap without the proper tool. Using a tap that is not suited for the material can result in excessive wear and eventual breakage. Always ensure the tap is compatible with the material you’re working with.

4. Excessive Tap Wear and Tear

Over time, taps experience wear from repeated use. This wear can lead to reduced cutting efficiency, heat buildup, and eventual breakage. Regularly inspecting and replacing worn taps is crucial to maintaining the quality and longevity of your tools.

5. Axis Synchronization Error

Improper alignment of the tapping tool on the CNC machine can cause unnecessary strain on the tap, increasing the likelihood of breakage. Ensuring precise synchronization between the tool and machine axes can prevent such errors.

6. Difficult Chip Breaking and Chip Evacuation

If chips are not cleared efficiently during the tapping process, they can clog the cutting area, putting additional pressure on the tap. This can lead to jamming and eventual breakage. Proper chip evacuation techniques, including the use of high-pressure coolant, are essential to prevent this issue.

7. Diameter of Bottom Hole Too Small

Tapping requires a specific hole diameter, and using a hole that is too small can place excessive strain on the tap, causing it to break. Always double-check the hole size before starting the tapping process to ensure it is within the recommended tolerance.

8. Poor Cutting Fluid and Lubricant Quality

Cutting fluids are essential for reducing friction and heat during the tapping process. If the fluid is of poor quality or insufficient, it can cause the tap to overheat and fail. Using the right type and quantity of cutting fluid can help preserve the life of your taps.

When a tap breaks during machining, it can halt progress and cause frustration. Fortunately, several solutions exist to help remove broken taps effectively. Below are the most common methods used in the industry:

1. Using Tap Extractors

Tap extractors are specially designed tools to grip and remove broken taps from a workpiece. They are ideal for smaller taps that have broken off just below the surface. Tap extractors work by applying a slight reverse rotation to extract the broken piece from the hole.

2. Manual Removal

For small tap breakages, manual removal may be sufficient. This method involves carefully using pliers or other hand tools to grasp and twist out the broken tap. However, this method can be time-consuming and might not work well for larger, more stubborn breakages.

3. Using a Pneumatic Drill to Remove Broken Taps

A pneumatic drill is another effective option for removing broken taps. This method uses air pressure to drill into the broken tap, gradually removing it without damaging the surrounding material. It’s particularly useful for taps that are deeply embedded in the workpiece.

4. Using a Chisel to Remove Broken Taps

In some cases, using a chisel to carefully chip away at the broken tap can be an effective method. This technique requires precision and patience, as it involves manually breaking apart the tap piece by piece.

5. Using an EDM Machine to Remove Broken Taps

Electrical Discharge Machining (EDM) is one of the most effective ways to remove broken taps. EDM uses electrical sparks to erode the material of the tap without damaging the workpiece. This method is especially useful for hard or deep-set taps.

6. Drilling

For some taps, drilling a small pilot hole into the center of the broken tap can allow you to remove it more easily. After drilling, a tap extractor or other removal method can be used to finish the job.

7. Using a Grinder to Remove Broken Taps

Grinding away the broken tap with a high-precision grinder can be an effective solution for smaller tap pieces. This method requires a steady hand to ensure that the surrounding material isn’t damaged.

8. Using Lubricants to Remove Broken Taps

Lubricants such as penetrating oils or cutting fluids can help loosen a stuck tap. By applying lubricant and allowing it to seep into the broken tap, you can reduce friction and make the extraction process easier.

9. Using Chemicals to Remove Broken Taps

In some cases, specialized chemicals are available to dissolve or loosen the material surrounding a broken tap. This method can be effective but should only be used when other options are not viable.

10. Welding to Remove Broken Taps

For very stubborn taps, welding a small nub to the center of the tap and then using a wrench to turn it may allow you to extract the broken piece. This technique should be used with caution, as it requires skill and careful execution.

Prevention is always better than cure, and knowing how to properly tap a hole can help avoid the need for tap removal. Here are some best practices to ensure that your tap remains operable during hand tapping:

At VMT, we understand the importance of precision in CNC machining. Whether you're dealing with broken taps or looking for high-quality CNC prototype machining services, our experienced team is here to help. Our custom CNC machining capabilities ensure that your parts are manufactured with the highest standards of quality and accuracy. We offer CNC machining services that include tap extraction and more. Contact us today to learn how we can assist with your CNC machining needs.

Dealing with broken taps is a challenging but manageable issue in CNC machining. Understanding the causes of tap failure and using the right techniques for tap removal can save valuable time and prevent costly mistakes. By following best practices, investing in quality tools, and using the proper methods for tap extraction, you can avoid tap breakage and ensure smoother machining operations.

FAQs

How do you remove a snapped tap?

To remove a snapped tap, you can use methods such as tap extractors, drilling a hole into the broken tap to facilitate removal, using an EDM (Electrical Discharge Machining) machine, or using a pneumatic drill. You could also carefully apply penetrating oils or lubricants to ease the removal process.

What is the proper tool for removing a broken tap?

The most common tool for removing a broken tap is a tap extractor, which is specifically designed to grip and remove broken taps from a workpiece. Other methods include using a grinder, pneumatic drill, or EDM machine, depending on the severity of the breakage.

What drill bit will drill out a broken tap?

A left-handed drill bit is commonly used for drilling out a broken tap. The left-handed rotation helps to loosen the broken tap, and in many cases, it can also reverse thread it out of the workpiece. Make sure to start with a small bit and gradually increase the size.

Which of the following is a method of removing a broken tap?

Methods for removing a broken tap include:

What is the method of removing a broken stud?

To remove a broken stud, you can use a stud extractor tool. This tool is designed to grip the stud and allow you to rotate it out of the workpiece. If the stud is deeply embedded, drilling it out or using a left-handed drill bit may also help remove it.

How do you remove a broken self-tapping screw?

A broken self-tapping screw can be removed using a screw extractor. This tool works by gripping the head of the screw and rotating it in reverse to unscrew it. For stubborn screws, drilling out the screw using a left-handed drill bit can also help.

Which tap displaces material instead of cutting it when making threads?

The type of tap that displaces material instead of cutting it is called a form tap. Unlike traditional cutting taps, which remove material, form taps push the material aside to create threads without generating chips.

How do you loosen a tap spindle?

To loosen a tap spindle, ensure the spindle nut is not overly tight. You can use a spindle wrench to apply controlled pressure to loosen the nut. If the spindle is stuck, applying penetrating oil and allowing it to sit can also help.

What is a replacement for a threading tap?

A thread forming tool or rolling die can be used as an alternative to a threading tap. These tools create threads by displacing material rather than cutting it. For large-scale applications, threading dies or rotary threaders can also be used.

How do you tap a damaged thread?

If a thread is damaged, you can repair it using a thread repair kit, which includes a helicoil or thread insert. You will need to clean the damaged threads, install the insert, and then tap the new threads to restore full functionality.

What is a tap thread cutter?

A tap thread cutter is a tool used in machining to cut internal threads in a hole. It works by rotating and cutting into the material to form a spiral groove that can accommodate a matching external thread, such as a bolt or screw.