15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

178 |

Published by VMT at Sep 16 2024

178 |

Published by VMT at Sep 16 2024

In the world of CNC machining and manufacturing, tapped and threaded holes play a critical role in assembling parts, securing fasteners, and providing mechanical integrity in structures. Whether you're dealing with custom CNC machining parts or large-scale production runs, understanding the differences between tapped holes and threaded holes is crucial for achieving high-quality results. This article explores the distinctions between these two types of holes, their processes, similarities, limitations, and applications. By the end of this guide, you'll have a comprehensive understanding of how both tapped and threaded holes are essential to CNC machining services and how to make the best choice for your specific project.

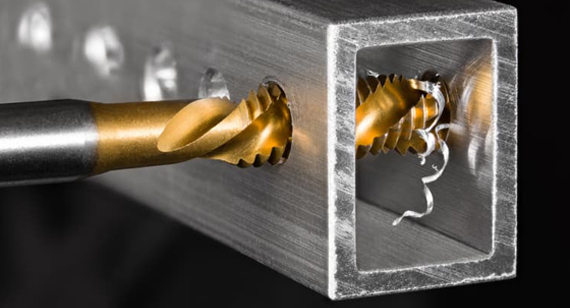

Tapping is the process of cutting internal threads into a pre-drilled hole using a tool called a tap. This tool, which has a series of ridges designed to match the desired thread profile, is inserted into the hole, and as it rotates, it cuts grooves into the interior surface of the hole, creating a thread pattern. Tapping is commonly used in both industrial and custom CNC machining applications for creating threaded holes that will accept screws, bolts, or other threaded fasteners.

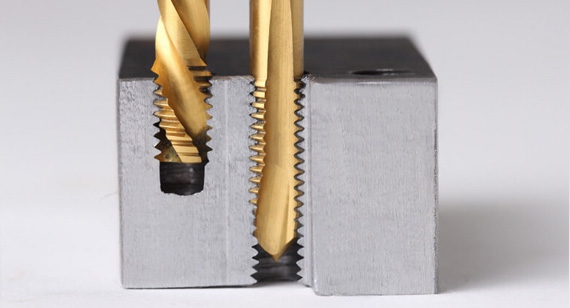

Tapping typically requires a pre-drilled hole (referred to as a "tap drill hole") that is slightly smaller in diameter than the final threaded hole. This ensures that the tap has sufficient material to cut into and form the threads. Once the threads are cut, the hole can securely hold a fastener with matching external threads, creating a strong mechanical connection.

There are different types of taps used in CNC machining, such as:

Tapping is ideal for both blind holes (holes that do not go all the way through a material) and through-holes (holes that pass entirely through a material). However, tapping is more prone to tool breakage, especially when working with hard materials or blind holes where chip removal can be challenging.

Threading, on the other hand, refers to the process of creating both internal (female) and external (male) threads on components. Internal threading is typically what we refer to when discussing tapped holes, but external threading is equally important for components such as screws, bolts, or studs. Threading can be done using various methods, including thread cutting (using a die or lathe), thread rolling, or even thread milling in CNC machining.

In CNC machining, threading can be accomplished by several methods:

Thread Milling: A CNC milling machine is used to create threads through a helical interpolation method. Thread milling allows for the cutting of both internal and external threads and offers more flexibility than tapping. For instance, a single thread mill can create different thread sizes, while tapping requires a specific tap for each thread size.

Thread Cutting: Thread cutting uses a lathe or other manual machine where the cutting tool creates the threads by removing material from the workpiece. This method is more traditional and is still used for larger parts or components that require custom threads.

Thread Rolling: This process involves deforming the material to create threads rather than cutting it. Thread rolling is commonly used for external threads on fasteners and offers excellent strength, as the grain structure of the material is not disrupted as it is with cutting processes.

Threading provides versatility, as it allows for both internal and external threads to be created on various components. This is critical in industries such as automotive, aerospace, and medical devices, where precision CNC machining is required.

Tapping and Threading - Comparison

When comparing tapping and threading, it's important to understand that these processes serve a similar function but differ in execution and application.

Process: Tapping is a specific form of threading used only to create internal threads, usually with a dedicated tapping tool. Threading, in contrast, encompasses a range of techniques that can be used to create both internal and external threads.

Flexibility: Threading offers greater flexibility, particularly when using CNC machines that can handle thread milling. Tapping, however, is more limited because it requires a specific tap for each thread size and type. Thread milling tools, on the other hand, can create different sizes of threads with a single tool, making it a more versatile solution for certain CNC machining jobs.

Tooling Requirements: Tapping requires specific tools (taps) for each thread type and size, whereas threading can often be accomplished with more general-purpose tools such as thread mills or cutting tools. This makes threading more adaptable in situations where multiple thread sizes are needed in a single part or when dealing with custom threads in prototype machining.

Speed and Efficiency: Tapping is often faster than thread milling because the tap can cut the entire thread in one operation. This makes tapping ideal for high-volume production runs where speed is critical. Thread milling, while more flexible, typically takes longer as it requires more passes to create the threads. However, thread milling provides more control over thread quality and is less likely to break during operation, particularly in difficult materials.

Material Considerations: Tapping is suitable for softer materials like aluminum, brass, and plastics, but can struggle with harder materials such as stainless steel or titanium. Thread milling, with its ability to generate less cutting pressure and heat, is better suited for harder materials, reducing the likelihood of tool breakage.

Thread Depth: One limitation of tapping is that it can be difficult to use in deep or blind holes. Thread milling and other threading techniques can handle deeper threads more effectively because they allow for better chip removal and reduce the risk of tool breakage.

Are Similar

Tapping and threading are similar processes with the core objective of producing functional threads for securely fastening components. In CNC machining, both processes are used to create threaded holes for screws, bolts, or other fasteners. The key difference lies in the tools and techniques used to achieve the final result. While tapping is faster and more efficient for creating internal threads, threading offers greater flexibility and can be applied to both internal and external threads.

Both methods are essential for industries where component precision and durability are critical. From custom CNC machining services to large-scale production at CNC machining factories, tapping and threading are indispensable tools in the manufacturing process.

Limitations

Thread Types: Both tapping and threading can be used to create the same types of threads, including metric, Unified National (UN), British Standard (BS), and Acme threads. However, the specific tool required for tapping must match the thread type exactly. The choice of thread type depends on the application’s requirements, such as load-bearing capacity and compatibility with other components. Tapping is limited to internal threads, while external threads require other threading processes, such as using dies.

Tool Breakage: Both tapping and threading face tool breakage issues, especially when working with harder materials or small, intricate holes. Proper tool selection, cooling, and cutting speeds are crucial to minimize tool wear and breakage.

Blind Hole Depth: Creating threads in blind holes presents challenges for both processes. Tapping requires careful planning, as the tool may jam or break if chips cannot be effectively removed. Thread milling offers better chip control, but it still poses challenges for very deep holes.

Material Limitations: Tapping and threading can encounter difficulties with certain materials. Extremely hard materials, like titanium, may lead to tool wear and breakage during tapping, while materials prone to “gumming,” such as plastics, may result in poor thread quality during threading. Choosing the correct tool and method for the material being processed is crucial for success.

Conclusion

In the comparison between tapped holes and threaded holes, both processes have their distinct advantages and limitations. Tapping is a faster and more efficient method for creating internal threads, particularly in high-volume production runs. Threading, on the other hand, offers greater flexibility and can be applied to both internal and external threads, making it ideal for more complex projects or materials that are difficult to machine.

Understanding the differences between tapping and threading is essential for choosing the right method for your CNC machining project. By considering factors such as material, thread type, and production volume, you can ensure that your threaded hole processing is both efficient and reliable. Whether you're working on custom CNC machining parts or mass-producing components, tapping and threading are vital processes that play a crucial role in the manufacturing of high-quality parts.

What is the difference between a threaded hole and a through hole?

A threaded hole contains internal threads designed to accept a screw or bolt, while a through hole is a hole that passes completely through a material, which may or may not be threaded.

Why is threading called tapping?

Threading is a general term that refers to the process of creating threads, while tapping is a specific form of threading used to create internal threads with a tap.

What is a tap hole?

A tap hole is a hole that has been drilled and then threaded using a tap, allowing a fastener to be screwed into it.

What does a 1420 threaded hole mean?

A 14-20 threaded hole refers to a hole with a 1/4-inch diameter (14 in fractional inches) and 20 threads per inch, using the Unified National thread standard.

How deep should a threaded hole be?

The depth of a threaded hole should generally be 1.5 to 2 times the diameter of the fastener being used to ensure a secure fit.

What is the minimum number of threads for a threaded hole?

The minimum number of threads is typically 1.5 times the diameter of the fastener, but it can vary depending on the application and load requirements.

What size drill should be used to tap a threaded hole?

The size of the drill bit depends on the size of the tap being used. Tap drill charts provide the recommended drill size for each tap size to ensure proper threading.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!