15 years one-stop China custom CNC machining parts factory

1452 |

Published by VMT at Sep 15 2024

1452 |

Published by VMT at Sep 15 2024

Automotive sheet metal manufacturing is a vital part of the automotive industry, playing a crucial role in creating everything from the car's frame to intricate components used in the engine bay and interior. The use of sheet metal in automotive manufacturing is essential for producing lightweight, strong, and durable parts that ensure vehicle safety, fuel efficiency, and aesthetic appeal. This comprehensive guide explores the different types of sheet metal used in the automotive sector, the various fabrication techniques employed, and the specific challenges and tips for ensuring high-quality results in automotive sheet metal manufacturing. Whether you are dealing with automotive CNC machining parts or custom CNC machining services, understanding the nuances of sheet metal fabrication is key to producing efficient, cost-effective automotive components.

Sheet metal manufacturing has become a cornerstone of the automotive industry for several reasons. The ability to shape, form, and customize metal sheets into a variety of shapes makes it an invaluable process for creating vehicle components that are lightweight, durable, and cost-effective. Let’s dive deeper into why sheet metal manufacturing is preferred in the automotive industry.

Design Flexibility: One of the most significant advantages of sheet metal manufacturing is its design flexibility. Modern automotive design demands sleek lines, aerodynamic shapes, and complex geometries, all of which can be achieved through sheet metal forming processes. Manufacturers can produce body panels, hoods, doors, and chassis components with precision, thanks to advanced fabrication techniques like CNC machining and laser cutting. This flexibility allows for design customization and innovation, helping automakers stand out in a competitive market.

Material Versatility: Sheet metal manufacturing offers the flexibility to work with a wide range of metals, each with its specific properties that cater to different automotive requirements. Aluminum, stainless steel, and galvanized sheets are just a few of the common materials used in the automotive industry. Each of these materials brings its own set of benefits—aluminum for lightweighting, stainless steel for corrosion resistance, and galvanized sheets for additional protection against the elements.

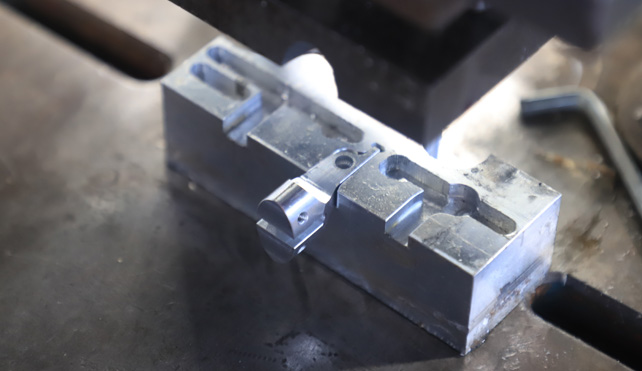

Precision and Accuracy: CNC machining and advanced fabrication techniques offer unmatched precision and accuracy in shaping and cutting sheet metal. This precision is critical in the automotive sector, where even minor deviations in dimensions can lead to fitting issues, inefficiencies, or compromised safety. With automated systems and CNC machining, manufacturers can achieve tight tolerances, ensuring that all parts meet the required specifications without the need for extensive post-processing.

Lightweight Components: With the push towards electric vehicles (EVs) and more fuel-efficient traditional vehicles, automotive manufacturers are increasingly focused on lightweighting. Sheet metal manufacturing, especially using materials like aluminum and magnesium, enables the production of lighter components without sacrificing structural integrity. Lighter parts reduce the overall weight of the vehicle, improving fuel efficiency and performance, which is particularly important for achieving stringent environmental standards.

Cost-Effective Production: Automotive sheet metal manufacturing processes, such as stamping, cutting, and bending, can be highly automated, leading to faster production times and reduced labor costs. The use of advanced machinery like CNC machines minimizes material waste, further reducing costs. Additionally, the scalability of these processes allows manufacturers to produce both small prototype runs and large-scale production efficiently, making it an economical choice for automakers.

The automotive industry uses a variety of sheet metals depending on the specific requirements of the part being manufactured. Factors such as weight, corrosion resistance, durability, and cost all play a role in determining which metal to use. Here’s a breakdown of the most commonly used sheet metals in automotive manufacturing:

Aluminum: Aluminum is highly regarded in the automotive industry for its lightweight properties and excellent strength-to-weight ratio. It’s commonly used in body panels, engine components, and structural parts. Aluminum’s ability to be easily formed and its natural corrosion resistance make it ideal for producing fuel-efficient vehicles and reducing emissions. With the rise of electric vehicles, aluminum is becoming even more critical as manufacturers aim to lower the overall weight of battery packs and chassis.

Stainless Steel: Stainless steel is valued for its durability and corrosion resistance, making it an excellent choice for parts exposed to harsh environmental conditions, such as exhaust systems, trim, and structural components. Stainless steel’s strength allows manufacturers to use thinner sheets without compromising on performance, which contributes to lightweight designs. Additionally, stainless steel’s ability to resist rust and maintain its appearance makes it a popular choice for visible components.

Cold Rolled Steel: Cold rolled steel is a widely used material in the automotive industry due to its high strength and smooth surface finish. The cold rolling process increases the steel’s strength by hardening it, making it suitable for high-stress applications such as suspension components, frames, and reinforcement beams. Its ability to be precision-machined and formed makes cold rolled steel a versatile choice for both structural and aesthetic parts.

Galvanized Sheet: Galvanized steel sheets are coated with zinc to provide enhanced protection against corrosion. This is particularly important for parts that are exposed to moisture and road salt, such as undercarriages and body panels. Galvanized sheet metal is often used in car bodies and frames because it offers a longer lifespan while maintaining strength and durability.

Titanium: While not as common due to its high cost, titanium is used in performance-oriented vehicles and in critical components such as exhaust systems, valves, and connecting rods. Titanium’s lightweight nature combined with its exceptional strength and corrosion resistance makes it ideal for applications where performance and longevity are paramount. It is also used in some automotive prototypes where durability under extreme conditions is required.

Copper and Brass: Copper and brass are typically used in electrical components due to their excellent conductivity. In the automotive industry, copper is found in electrical wiring, connectors, and radiators, where efficient heat transfer is necessary. Brass is used in parts like fittings and bearings, providing a good balance between strength, malleability, and resistance to corrosion.

Magnesium: Magnesium is the lightest structural metal and is used in automotive manufacturing to reduce weight while maintaining strength. It’s often alloyed with aluminum to improve its properties and is used in components such as engine blocks, gearboxes, and steering wheels. Magnesium’s lightweight properties contribute to fuel efficiency and performance, but it is more expensive and less commonly used than aluminum or steel.

Sheet metal fabrication involves several techniques to cut, form, and join metal sheets into functional automotive components. The choice of technique depends on the material, the desired geometry, and the production volume. The most common techniques include cutting, forming, and joining, each offering distinct advantages for different applications.

Sheet Metal Cutting Techniques for Automotive

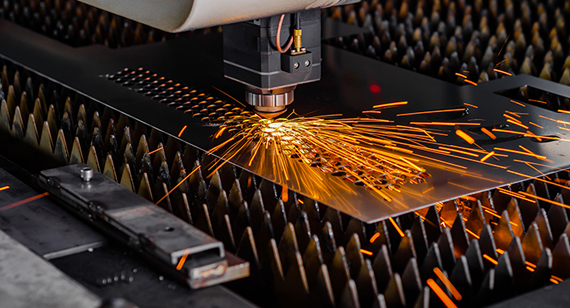

Laser Cutting:

Laser cutting is a highly precise method used to cut sheet metal with extreme accuracy. It uses a high-powered laser beam to vaporize the material along a specified path. Laser cutting is particularly useful for complex shapes and intricate designs, making it ideal for automotive components that require precision and detailed work, such as body panels and custom trim.

Advantages: Laser cutting offers high precision and clean edges with minimal material waste. It can be used on a wide variety of metals, including aluminum, steel, and titanium. Additionally, laser cutting is a non-contact process, meaning the metal isn’t subjected to mechanical stress, reducing the risk of warping or deformation.

Plasma Cutting:

Plasma cutting involves the use of a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials such as steel and aluminum. It’s a fast and efficient method that’s commonly used in automotive manufacturing for cutting thick metal sheets and creating parts with less intricate designs.

Advantages: Plasma cutting is faster and more affordable than laser cutting for thicker metals. It’s highly effective for cutting larger, heavier components, making it ideal for frames, chassis, and other structural parts.

Shearing:

Shearing is a mechanical cutting process that involves applying a shear force to cut straight lines across a sheet of metal. It’s an efficient method for creating straight cuts and is often used for cutting metal sheets into smaller sections or preparing them for further forming processes.

Advantages: Shearing is a cost-effective and straightforward method for making straight cuts quickly and accurately. It’s suitable for cutting various thicknesses of sheet metal and doesn’t require any heat, which preserves the metal’s original properties.

Sheet Metal Forming Techniques for Automotive

Forming techniques are essential for shaping flat sheet metal into three-dimensional automotive components. These processes include bending, pressing, and stamping, and they are critical for creating parts such as body panels, fenders, and hoods.

Bending:

Bending is one of the most common forming techniques used to create curves and angles in sheet metal. The metal is placed into a press brake, and a die is used to bend the material to the desired angle. Bending is essential for creating parts like brackets, enclosures, and reinforcement components.

Advantages: Bending is highly versatile, allowing for the creation of both simple and complex shapes. It’s also cost-effective, particularly for large production runs, and can be used with a wide variety of metals, including aluminum, steel, and stainless steel.

Stamping:

Pressing involves using a hydraulic or mechanical press to apply force to the sheet metal, forming it into a specific shape. This technique is commonly used for producing large automotive components such as body panels, doors, and hoods.

Advantages: Pressing is ideal for high-volume production, as it can produce consistent and accurate parts quickly. It’s particularly useful for creating large, complex components that require uniform thickness and precise dimensions.

Sheet Metal Joining Techniques for Automotive

Joining techniques are critical in assembling individual sheet metal components into complete automotive assemblies. Welding and riveting are two of the most common methods used in the automotive industry.

Welding:

Welding involves fusing two or more metal parts together using heat and pressure. In automotive manufacturing, various welding techniques are used, including MIG, TIG, and resistance welding, depending on the material and the specific application.

Advantages: Welding provides strong, permanent bonds that are essential for structural components. It can be used on a variety of metals, including aluminum, steel, and stainless steel. Welding is also versatile, allowing for both spot and seam welds depending on the part’s design.

Riveting:

Riveting is a mechanical joining process where metal fasteners (rivets) are inserted into pre-drilled holes to join two or more pieces of sheet metal together. Riveting is often used in situations where welding is impractical or where disassembly may be required, such as in the assembly of body panels.

Advantages: Riveting offers a quick and reliable way to join parts without the need for heat, making it suitable for materials that may be sensitive to high temperatures. Rivets also provide a clean and aesthetic finish, particularly for visible components like exterior panels.

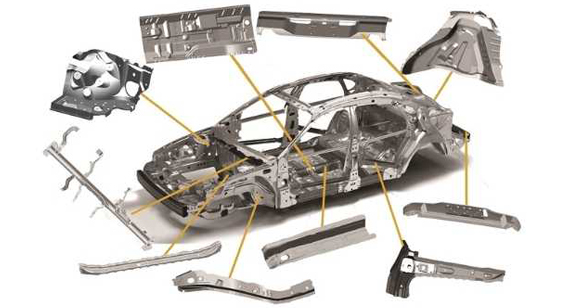

Sheet metal is used to fabricate a wide range of automotive components, from the car’s body to its interior parts. Here are some key applications of sheet metal in automotive manufacturing:

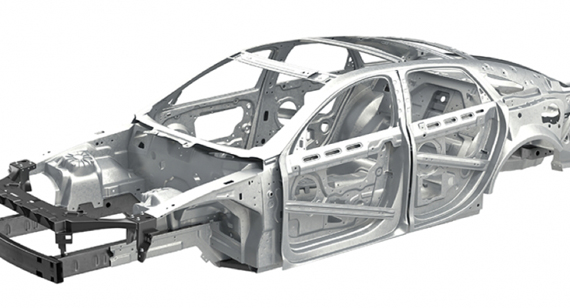

Body and Frame: The car’s body and frame are primarily made from sheet metal. Aluminum, steel, and galvanized sheets are used to create strong, lightweight structures that provide safety and performance. Sheet metal allows manufacturers to create sleek, aerodynamic designs that contribute to the vehicle’s overall efficiency.

Automobile Customization: Custom automotive fabrication often involves sheet metal work to create unique body panels, fenders, and trim. Sheet metal is also used to modify existing vehicles, whether for aesthetic purposes or performance upgrades, such as adding custom grilles, spoilers, or exhaust systems.

Antique Car Restoration: Restoring antique or classic cars often involves recreating parts that are no longer in production. Sheet metal fabrication is essential for replicating original body panels, fenders, and other parts, ensuring that the restored vehicle maintains its authenticity and appearance.

Building a Roll Cage: Roll cages are safety structures installed in performance or race cars to protect the occupants in the event of a rollover or crash. Fabricating a roll cage from sheet metal ensures the structure is strong enough to withstand high impacts while maintaining the vehicle’s overall performance.

Sheet metal fabrication in the automotive industry comes with its own set of challenges. Here are some key considerations when choosing sheet metal fabrication processes and materials:

Maintaining Precision: Precision is critical in automotive manufacturing to ensure that all parts fit together seamlessly. CNC machining and laser cutting are essential for achieving the tight tolerances required in automotive sheet metal fabrication. Manufacturers must invest in high-quality equipment and skilled operators to maintain precision and consistency.

Ensuring Material Quality: The quality of the sheet metal used in automotive manufacturing directly impacts the durability, safety, and performance of the final product. It’s essential to source high-grade materials that meet industry standards for strength, corrosion resistance, and formability. Additionally, proper storage and handling of materials are crucial to prevent contamination or damage before fabrication.

Manufacturing Tolerances: Automotive parts must meet strict tolerances to ensure safety and performance. Working with tight tolerances requires careful planning, precise machining, and rigorous quality control processes. Manufacturers must regularly inspect and test parts to ensure they meet the required specifications.

At VMT, we specialize in high-quality sheet metal fabrication for the automotive industry. Our custom CNC machining services and advanced manufacturing technologies ensure that every part we produce meets the highest standards of precision and durability. Whether you need prototype machining or large-scale production, VMT offers reliable and cost-effective solutions for all your automotive sheet metal fabrication needs.

Automotive sheet metal manufacturing is a critical aspect of modern vehicle production, offering versatility, strength, and precision. By understanding the different types of sheet metal, fabrication techniques, and challenges involved, manufacturers can create high-performance automotive components that meet the demands of the industry. Whether for custom CNC machining parts or large-scale production, sheet metal fabrication is key to achieving innovation and efficiency in automotive manufacturing.

What is the thickness of automotive sheet metal?

The thickness of automotive sheet metal typically ranges from 0.5 mm to 2.0 mm, depending on the part and material used. Thicker sheets are generally used for structural components, while thinner sheets are used for body panels and exterior trim.

What metals are used in the automotive industry?

Common metals used in the automotive industry include aluminum, stainless steel, cold rolled steel, galvanized steel, titanium, and magnesium. Each metal is selected based on its properties, such as strength, corrosion resistance, and weight.

What types of sheet metal are used for automotive bodies?

Automotive bodies are typically made from aluminum, cold rolled steel, or galvanized steel due to their strength, formability, and corrosion resistance.

What are the best welding methods for automotive sheet metal?

MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are commonly used for automotive sheet metal. Spot welding is also widely used for joining body panels in high-volume production.

What is the thickness of aluminum for automotive bodies?

The thickness of aluminum used in automotive bodies typically ranges from 0.8 mm to 1.2 mm, depending on the specific application and design requirements.

Which metal is best for making a car body?

Aluminum and steel are the most commonly used metals for car bodies due to their balance of strength, weight, and cost-effectiveness. Aluminum is preferred for lightweight vehicles, while steel offers superior strength and durability.

What is the most commonly used material for car body panels?

Steel, particularly cold rolled and galvanized steel, is the most commonly used material for car body panels due to its strength, formability, and corrosion resistance.

What is the thinnest sheet metal you can get?

Sheet metal can be as thin as 0.2 mm, but the minimum thickness depends on the material and application.