15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

148 |

Published by VMT at May 12 2024

148 |

Published by VMT at May 12 2024

This article aims to delve into the application and advantages of copper materials in automotive radiators, and elucidate the pivotal role of CNC machining processes in copper material machining. Through this article, readers will gain insights into the unique position of copper materials in automotive radiator design, as well as how CNC machining factories utilize their professional expertise to provide high-quality copper CNC machining parts and CNC machining services for the automotive industry.

Introduction

With the rapid development of the automotive industry, there is an increasing demand for high-performance automotive radiators. Copper materials, with their excellent thermal conductivity, corrosion resistance, and machinability, have found widespread applications in automotive radiators. Simultaneously, the development of CNC machining processes has provided strong support for the precise machining of copper materials. This article will discuss in detail the application, advantages, and CNC machining processes of copper materials in automotive radiators.

Application and Advantages of Copper Materials in Automotive Radiators

Application:

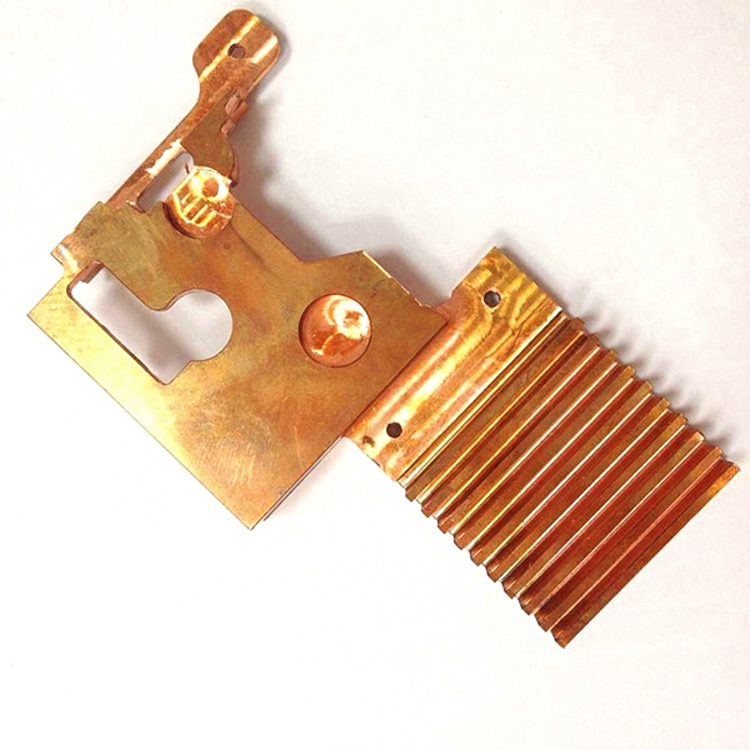

Copper materials are primarily used in the manufacturing of radiator fins in automotive radiators. Radiator fins are crucial components responsible for rapidly dissipating heat generated by the engine. The high thermal conductivity of copper enables radiator fins to quickly transfer heat to the radiator's surface, thereby enhancing heat dissipation efficiency.

Advantages:

The advantages of copper materials in automotive radiators are mainly reflected in the following aspects:

(1) High Thermal Conductivity: Copper has a much higher thermal conductivity coefficient compared to other metal materials, enabling it to rapidly transfer heat from the engine to the radiator, thereby improving heat dissipation efficiency and ensuring the normal operation of the engine.

(2) Corrosion Resistance: Copper materials exhibit excellent corrosion resistance, capable of resisting the corrosion of various corrosive substances in the automotive operating environment, thus extending the service life of radiators.

(3) Machinability: Copper materials are easy to process into various shapes and sizes, meeting the diverse design requirements of automotive radiators.

Application of CNC Machining Processes in Copper Material Processing

CNC machining processes are high-precision and high-efficiency machining methods widely used in the processing of copper materials. CNC machining factories, through advanced CNC machining equipment and technology, can achieve precise cutting, drilling, milling, and other machining operations on copper materials, thereby producing copper CNC machining parts that meet the required specifications.

In the manufacturing process of copper material automotive radiators, CNC machining processes play a crucial role. Through precise CNC machining, the shape, dimensions, and surface quality of radiator fins can meet design requirements, thereby improving the overall performance of radiators. Furthermore, CNC machining processes can achieve automated production, enhancing production efficiency and product quality while reducing manufacturing costs.

CNC Machining Factories and CNC Machining Services

As professional machining service providers, CNC machining factories possess extensive experience and advanced technical equipment, enabling them to provide high-quality copper CNC machining parts and CNC machining services for the automotive industry. These factories typically have a variety of CNC machining equipment models to meet the diverse machining needs of different customers. Additionally, they have professional technical teams capable of providing customized machining services according to specific customer requirements, offering personalized solutions.

CNC machining services encompass not only part machining but also mold manufacturing, customized design, and technical consultation, among other aspects. CNC machining factories can provide comprehensive services ranging from product design to finished product manufacturing according to customer needs, facilitating rapid product development and production for customers.

Conclusion

The application and advantages of copper materials in automotive radiators, along with the development of CNC machining processes, have collectively driven the performance enhancement and industrial upgrading of automotive radiators. With the continuous advancement of technology and changes in the market, we believe that copper materials and CNC machining processes will continue to play important roles in the future, making greater contributions to the sustainable development of the automotive industry.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!