15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

227 |

Published by VMT at May 11 2024

227 |

Published by VMT at May 11 2024

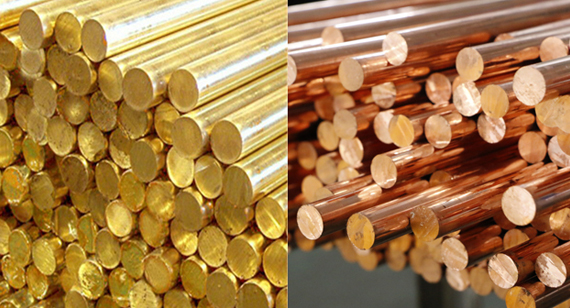

The marine environment imposes high demands on material performance due to its unique physical, chemical, and biological characteristics. Copper materials have been widely used in marine environments due to their excellent corrosion resistance, thermal conductivity, and machinability. This article will discuss the application, advantages, corrosion issues, and protective measures of copper materials in marine environments.

Application and Advantages of Copper Materials in Marine Environments:

Application Areas:

Copper materials have extensive applications in marine environments, including submarine oil pipelines, shipbuilding, marine wind power generation equipment, seawater desalination equipment, and more. These equipment and components need to withstand corrosion from seawater, high temperature and pressure impacts, and wave erosion, for which copper materials are well-suited, making them indispensable in the marine industry.

Advantages:

The advantages of copper materials in marine environments mainly include the following:

Excellent corrosion resistance: Copper materials can form a dense oxide film in seawater, effectively protecting the metal matrix and slowing down the corrosion rate. Additionally, copper materials have antibacterial and antifouling capabilities, helping to maintain the cleanliness and stable operation of marine equipment.

Good thermal conductivity: Copper materials have a high thermal conductivity coefficient, contributing to excellent heat dissipation performance of equipment in marine environments, thus reducing equipment failure rates.

Machinability: Copper materials have good machinability, capable of meeting the machining requirements of various complex shapes and precision parts.

Corrosion Issues of Copper Materials:

Despite the excellent corrosion resistance of copper materials in marine environments, they still face corrosion issues during long-term use. The main causes of corrosion include corrosive substances such as chloride ions and sulfides in seawater, as well as electrochemical corrosion caused by marine organism attachment. Corrosion issues not only affect the service life and performance of equipment but also pose safety hazards.

Protective Measures for Copper Materials:

To effectively address the corrosion issues of copper materials, a series of protective measures need to be taken:

Surface coating: Apply a coating that can block the external environment, such as paint or polymers, on the surface of copper materials to reduce corrosion.

Electrochemical protection: Protect copper materials as cathodes by applying an external electric current. This method is commonly used for corrosion protection of underwater pipelines and ships.

Alloying: Alloy copper with other metals to improve its corrosion resistance. For example, adding elements such as zinc, tin, or aluminum to form brass or bronze alloys can further enhance the corrosion resistance of copper materials.

Antioxidants: Apply chemical substances to the surface of copper materials to form a protective oxide film, blocking the contact of oxygen.

Cleaning and maintenance: Regularly clean and maintain copper materials to remove surface dirt and corrosion products, helping to maintain their excellent corrosion resistance.

The Role of CNC Machining Factories in Copper Material Applications:

As an integral part of the marine industry, CNC machining factories possess professional CNC machining technology and equipment, enabling them to provide high-quality copper CNC machining parts and services for the marine industry. Through precise CNC machining technology, CNC machining factories can produce copper parts with high precision that meet design requirements, satisfying the machining needs of marine equipment for complex shapes and precision requirements. Moreover, CNC machining factories can provide customized copper material solutions according to customer needs, helping customers address corrosion issues in the marine environment.

Conclusion:

Copper materials have extensive applications and advantages in marine environments, making them indispensable in the marine industry. However, their corrosion issues cannot be ignored. By adopting effective corrosion protection measures and leveraging the professional expertise and services of CNC machining factories, the performance and service life of copper materials in marine environments can be ensured. In the future, with the continuous development of the marine industry, the application of copper materials will become more extensive, and their corrosion and protection issues will receive deeper research and attention.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!