15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

134 |

Published by VMT at May 13 2024

134 |

Published by VMT at May 13 2024

This article delves into the applications and advantages of two CNC machining technologies, etching, and laser engraving, in part manufacturing. It compares and analyzes their differences, providing guidance on selecting the appropriate method. Additionally, the article explores the application areas of etching and laser engraving, showcases VMT CNC Machining Factory's manufacturing capabilities, and addresses common questions. Readers will gain comprehensive knowledge of etching and laser engraving CNC machined parts, offering valuable guidance for practical applications.

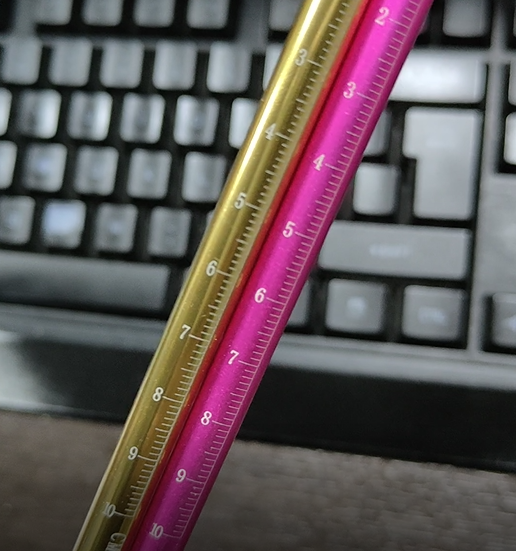

Overview of Etching

Etching is a machining technique that utilizes chemical or physical methods to create patterns or text on the surface of metals or non-metals. In the CNC machining field, etching technology, known for its high precision and efficiency, is widely used for surface processing of various materials. CNC machined parts produced through etching exhibit clear patterns, delicate lines, and strong corrosion resistance, making them widely used in electronics, medical equipment, automotive components, and other fields.

Overview of Laser Engraving

Laser engraving, also known as laser marking or laser etching, is a machining method that uses a high-energy laser beam to etch the surface of materials. CNC machined parts produced through laser engraving feature fast processing speed, non-contact processing, and suitability for various materials. Laser engraving technology enables the creation of various forms of markings such as text, patterns, and QR codes, widely applied in electronics, communications, hardware, and other industries.

Differences Between Etching and Laser Engraving

Processing Principle: Etching relies on chemical or physical reactions to form patterns on the material surface, while laser engraving directly applies a laser beam to the material surface for etching.

Applicable Materials: Etching is suitable for a wide range of materials including metals, glass, and plastics, whereas laser engraving is more suitable for hard materials such as metals and non-metals.

Processing Precision: Laser engraving offers high processing precision, capable of achieving finer patterns and text. However, under certain material and process conditions, etching can also achieve high precision.

Cost: Etching typically requires special chemical reagents and equipment, resulting in relatively higher costs, whereas laser engraving equipment is relatively simple, leading to lower costs.

Considerations for Surface Manufacturing of Etched and Laser Engraved CNC Machined Parts

Material Selection: Choose appropriate materials based on the functionality and operating environment of the parts for etching or laser engraving.

Processing Parameters: Set reasonable processing parameters such as etchant concentration, temperature, laser power, and scanning speed to ensure processing quality and efficiency.

Pre-treatment and Post-treatment: Conduct necessary pre-treatment and post-treatment on the processed surface, such as cleaning, polishing, and rust prevention, to improve the appearance and performance of the parts.

Applications of Etching and Laser Engraving

Etching and laser engraving have extensive applications in the CNC machining field. Etching is commonly used to produce high-precision, high-demand metal plaques, nameplates, and decorative parts, while laser engraving is widely applied in the identification, traceability, and anti-counterfeiting of electronic products, medical equipment, automotive components, and other fields.

How to Choose Between Etching and Laser Engraving?

When selecting CNC machined parts for etching or laser engraving, consider the following factors:

Functionality and Operating Environment of the Parts: Choose the appropriate machining technology based on the specific requirements of the parts.

Material Characteristics: Consider the hardness, corrosion resistance, and wear resistance of the material to select the suitable machining method.

Processing Precision and Cost: Evaluate the advantages and disadvantages of etching and laser engraving in terms of processing precision and cost, and make a rational choice.

Manufacturing Capabilities of VMT

VMT CNC Machining Factory possesses advanced etching and laser engraving equipment, along with rich machining experience and technical strength. We are committed to providing customers with high-quality etched and laser engraved CNC machined parts, as well as comprehensive CNC machining services. Whether it's precision part machining or complex pattern design, we can meet the needs of our customers.

FAQs About Etching and Laser Engraving CNC Machined Parts

Q: Which is more suitable for machining metal parts, etching, or laser engraving?

A: It depends on the specific application requirements and material characteristics. For some metal materials, etching may be more suitable, while for others, laser engraving may have advantages.

Q: How to ensure the processing quality of etching and laser engraving?

A: Key to ensuring processing quality is selecting appropriate materials, setting reasonable processing parameters, and conducting necessary pre-treatment and post-treatment.

Q: How do the costs of etching and laser engraving compare?

A: The costs of etching and laser engraving vary depending on factors such as materials, equipment, and processes. Generally, laser engraving equipment is relatively simple, resulting in lower costs, while etching requires special chemical reagents and equipment, leading to higher costs.

Conclusion

Etching and laser engraving, as crucial technologies in the CNC machining field, each have their unique advantages and applications. When choosing between etching and laser engraving CNC machined parts, consider factors such as part functionality, material characteristics, processing precision, and cost. With advanced equipment and rich experience, VMT CNC Machining Factory can provide customers with high-quality etched and laser engraved CNC machined parts and CNC machining services. Through this article's introduction and guidance, readers will gain a deeper understanding of etching and laser engraving CNC machined parts, enabling them to make the right choices for practical applications.

In the CNC machining field, the applications of etching and laser engraving technologies are becoming increasingly widespread, providing efficient and precise solutions for part manufacturing. However, each technology has its unique scope and limitations, making it crucial to choose the right machining method. Through this discussion, we hope to provide valuable insights to readers, helping them achieve better results in CNC machined part manufacturing.

With the continuous advancement of technology, etching and laser engraving technologies will continue to develop and improve. We look forward to seeing more innovative application cases driving the CNC machining field to higher levels. Meanwhile, VMT CNC Machining Factory will continue to invest in research and development, enhance manufacturing capabilities, and provide customers with better services.

In future development, we believe that etching and laser engraving CNC machined parts will play increasingly important roles in more fields, offering more efficient and environmentally friendly solutions for industrial manufacturing. We look forward to cooperating with customers to promote the development of CNC machining technology and contribute to the prosperity and progress of society.

In summary, etching and laser engraving, as two important technologies in the CNC machining field, have broad application prospects and market demand. We should fully understand their characteristics and advantages, combine them with practical needs for selection and application, to achieve optimal machining results and economic benefits. Meanwhile, we should also pay attention to the development and application of new technologies, continuously improve our technical capabilities and competitiveness, and contribute to the development of the industrial manufacturing field.

It is worth noting that the etching and laser engraving technologies mentioned in this article are only a part of the CNC machining field, and actual applications may involve other various technologies and methods. Therefore, in practical applications, comprehensive analysis and selection should be conducted based on specific requirements and conditions.

Furthermore, with the continuous development of technology, new machining technologies and methods will emerge. Therefore, we need to maintain keen insight, continuously learn and master new technologies to adapt to the ever-changing market demands.

Finally, regardless of the chosen machining technology, attention should be paid to processing quality and safety. During the machining process, strict adherence to operating procedures is necessary to ensure the safety of equipment and personnel. At the same time, strict quality control of processing should be conducted to ensure that the performance and reliability of parts meet the expected requirements.

In conclusion, etching and laser engraving, as two important technologies in the CNC machining field, have broad prospects and market demand. We should fully understand their characteristics and advantages, combine them with practical needs for selection and application, to achieve optimal machining results and economic benefits. At the same time, we should pay attention to the development and application of new technologies, continuously improve our technical capabilities and competitiveness, and contribute to the development of the industrial manufacturing field.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!