15 years one-stop China custom CNC machining parts factory

423 |

Published by VMT at Sep 05 2024

423 |

Published by VMT at Sep 05 2024

Tapping and threading are fundamental processes in the world of CNC machining, each essential for creating threaded holes used in assembling components with screws, bolts, or other fasteners. While they may seem similar, tapping and threading differ significantly in technique, tools, and applications. This article provides a detailed comparison between tapping and threading, exploring their differences, similarities, advantages, and limitations. By understanding these processes, manufacturers and engineers can make informed decisions to achieve optimal results in CNC machining, whether in mass production or custom CNC machining projects.

Tapping and threading are both methods used to create threads in a hole, allowing for the insertion of a screw or bolt. These processes are critical in manufacturing, particularly in industries that require precision CNC machining parts, such as automotive, aerospace, and electronics.

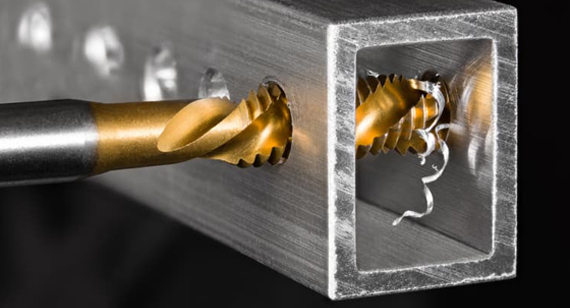

Tapping is the process of cutting internal threads in a pre-drilled hole using a tool known as a tap. The tap is rotated into the hole, removing material to form the threads that will accommodate a corresponding screw or bolt. Tapping is a straightforward and widely used method in CNC machining services, suitable for creating threads in various materials, including metals and plastics. Taps come in different forms, including taper taps, plug taps, and bottoming taps, each designed for specific applications and thread depths. Tapping is particularly useful in scenarios where quick, reliable threading is required, especially in smaller holes or when dealing with materials that are easy to machine.

Formula for Tap Size for ANSI Threads

To determine the appropriate tap size for ANSI threads, machinists use a specific formula:

Tap Drill Size = Major Diameter −1 / Number of Threads per Inch (TPI)

For instance, if you have a ¼”-20 UNC thread, the major diameter is 0.250 inches, and the TPI is 20. Plugging these values into the formula:

Tap Drill Size = 0.250 −1/20 = 0.250 − 0.050 = 0.200 inches

This calculation is essential for ensuring that the hole is the correct size for tapping, providing enough material to form strong threads while avoiding excessive force during tapping, which could lead to tool breakage.

A threaded hole is a hole that has internal threads, allowing it to accommodate a threaded fastener, such as a screw or bolt. These holes are crucial in the assembly of CNC machining parts, providing secure and removable connections. Threaded holes can be created through tapping or other threading processes, and they are designed to meet specific standards, such as metric or imperial thread sizes, depending on the application. In precision CNC machining, threaded holes must be made with high accuracy to ensure that the fasteners fit correctly and maintain the structural integrity of the assembled parts.

While tapping and threading both create threads in a material, they differ in their approach, tools, and applications. Understanding these differences is key to selecting the appropriate method for a given project.

Differences

The primary difference between tapping and threading lies in the method of creating the threads. Tapping uses a tap, which is a tool specifically designed to cut internal threads directly into a pre-drilled hole. Threading, on the other hand, often refers to creating external threads on a rod or bolt using a die or threading lathe, although it can also refer to internal threading in some contexts using a thread mill or lathe. Tapping is generally faster and more straightforward, making it ideal for mass production in a CNC machining factory. Threading, particularly when done with a thread mill, allows for greater flexibility and precision, making it suitable for custom CNC machining where unique or complex thread profiles are required.

Similarities

Despite their differences, tapping and threading share several similarities, particularly in their application and purpose.

Thread Types

Both tapping and threading are used to create various thread types, including standard metric threads, UNC/UNF threads, and specialized threads like Acme or square threads. The choice of thread type depends on the specific requirements of the application, such as the need for strength, precision, or specific fastening capabilities.

Tool Breakage

Tool breakage is a common risk in both tapping and threading processes, particularly when working with hard materials or when the cutting tools are not properly aligned or lubricated. Both methods require careful handling and the right choice of cutting speed, feed rate, and lubrication to minimize the risk of breaking taps or threading dies.

Blind Hole Depth

When creating threads in blind holes—holes that do not pass all the way through the material—both tapping and threading require precise control over the depth to avoid damaging the bottom of the hole. Taps designed for blind holes, such as bottoming taps, are used to ensure that threads are cut to the full depth of the hole.

Material Restrictions

Both tapping and threading are affected by the material being machined. Softer materials like aluminum or brass are easier to tap and thread, while harder materials like stainless steel or titanium may require special taps, dies, or thread mills, and possibly pre-treatment of the material to make it more machinable.

Limitations

Tapping and threading each have their own limitations. Tapping is generally limited by the depth of the hole, as the tap must be able to fully penetrate the material to cut the threads. Threading, especially with a thread mill, can handle deeper holes and more complex thread profiles but is typically slower and requires more precise control. Additionally, threading tools can be more expensive and may require specialized equipment, particularly in custom CNC machining.

Interchange

In some cases, tapping and threading can be used interchangeably, especially in situations where the threads are not critical for the application. However, the choice between the two methods often depends on the specific requirements of the project, such as the need for speed, precision, or the type of material being machined.

A quick comparison between tapping and threading highlights the key factors to consider when choosing between these two methods:

Cost

Tapping is generally more cost-effective, especially for high-volume production runs, as it is a faster process and requires less specialized equipment. Threading, particularly with thread mills or lathe threading, can be more expensive due to the cost of tools and the slower machining time.

Speed

Tapping is typically faster than threading, making it ideal for applications where speed is a priority. Threading, while slower, offers greater precision and the ability to create more complex thread profiles.

Volume

For high-volume production, tapping is often the preferred method due to its speed and efficiency. Threading is more suited to lower-volume, high-precision work, such as custom CNC machining or prototype development.

Material

The choice between tapping and threading can also depend on the material being machined. Softer materials are easier to tap, while harder materials may require threading with specialized tools to achieve the desired results without damaging the material or tools.

Choosing between threaded and tapped holes depends on various factors, including the application, material, and required precision. If speed and efficiency are priorities, and the material is relatively easy to machine, tapping may be the best choice. For applications requiring higher precision, complex thread profiles, or when working with harder materials, threading with a thread mill or lathe might be more appropriate. Additionally, consider the load-carrying capacity of the threads, as well as the ease of assembly and disassembly, when making your decision.

Things to Consider When Making Your Selection

Materials

The material being machined plays a significant role in the choice between tapping and threading. Softer materials, such as aluminum or plastic, are easier to tap, while harder materials, like stainless steel or titanium, may be better suited for threading with a thread mill or lathe. The machinability of the material will also influence the choice of cutting tools and the necessary speed and feed rates.

Precision

For applications requiring high precision, such as in aerospace or medical device manufacturing, threading with a thread mill or lathe may be preferred due to the greater control and accuracy it offers. Tapping is still precise but may not achieve the same level of accuracy as threading, especially in critical applications.

Load-Carrying Capacity

The load-carrying capacity of the threads is another important consideration. Threading, particularly with rolled threads, can produce stronger threads with higher load capacity compared to cut threads created by tapping. For high-stress applications, threading may be the better option.

Threaded or Through-Hole Connections

Deciding between a threaded or through-hole connection will also influence the choice between tapping and threading. Tapping is often used for blind holes where the threads need to stop at a specific depth, while threading may be used for through-holes or when a precise thread profile is required throughout the hole.

Safety and Durability

Safety and durability are critical in choosing between tapping and threading. Tapping is quicker but can result in weaker threads if not done correctly, leading to potential failures in high-stress applications. Threading, particularly with rolled threads, offers greater durability and is better suited for applications where safety and long-term reliability are paramount.

Both tapping and threading have their own advantages and disadvantages, depending on the application:

Advantages of Tapping:

Faster process, making it ideal for high-volume production.

Simpler tooling requirements, reducing overall costs.

Suitable for creating internal threads in small holes.

Disadvantages of Tapping:

Limited to shallower holes due to the need for the tap to fully penetrate the material.

Risk of tap breakage, especially in harder materials.

Less flexible in creating complex or custom thread profiles.

Advantages of Threading:

Greater precision and flexibility, especially with thread milling.

Ability to create stronger threads, particularly with rolled threads.

Suitable for deeper holes and more complex thread profiles.

Disadvantages of Threading:

Slower process, which may not be ideal for high-volume production.

Higher cost due to more specialized tools and equipment.

Requires more skilled operators and precise control.

Blind holes and through holes are used in different scenarios based on the assembly requirements. Blind holes, where the hole does not go through the entire material, are often used when the other side of the workpiece must remain intact or when a flush surface is needed on one side. Through holes, which pass completely through the material, are used when a fastener needs to extend all the way through the workpiece, often secured with a nut on the opposite side. The choice between tapping and threading can also depend on whether the hole is blind or through, with tapping being more common for blind holes and threading for through holes.

Both tapping and threading require specific tools, each suited to the method and material being used:

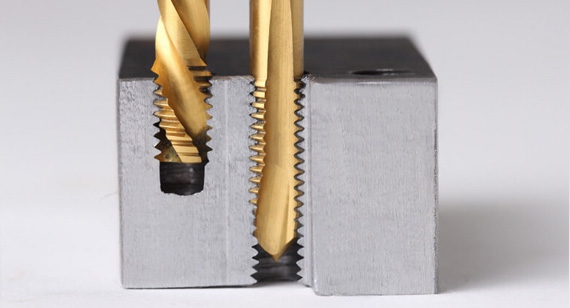

Tapered Taps

Tapered taps have a gradual taper at the end, making them ideal for starting the threading process. They are used to begin cutting threads in a pre-drilled hole, with the tapered design allowing for easier alignment and reducing the risk of tool breakage.

Plug Taps

Plug taps are used to continue the threading process after a tapered tap has started the thread. They have fewer tapered threads and more full-sized cutting edges, making them versatile for threading through holes or finishing the threads in a blind hole.

Bottom Taps

Bottom taps have full-sized cutting edges with minimal taper, designed for cutting threads to the bottom of a blind hole. These taps are essential when the full depth of the hole needs to be threaded, ensuring a strong and secure connection.

Choosing the correct drill size for tapping is critical for achieving accurate threads:

Check Tap Size

Start by determining the tap size needed for your project. The tap size will dictate the diameter of the hole that needs to be drilled.

Reference Drill Chart

Use a tap drill chart to find the correct drill bit size for the tap you are using. The chart provides the recommended drill size for various thread sizes and types, ensuring that the hole is properly sized for the tap.

Pre-Drilling

Pre-drilling the hole to the correct size is essential for successful tapping. Ensure that the hole is drilled straight and to the correct depth, especially when working with blind holes.

Material Considerations

Consider the material being tapped, as harder materials may require slightly larger drill sizes to reduce the force needed to tap the threads, preventing tool breakage and ensuring clean threads.

Understanding the different cutting tools and thread mills available is crucial for selecting the right tools for your threading or tapping project. Thread mills offer greater flexibility and precision, especially for creating custom thread profiles or working with challenging materials. Cutting tools, such as taps, are more straightforward and cost-effective, making them suitable for high-volume production where standard threads are required.

At VMT, we offer comprehensive CNC machining services, including precision threading and tapping. Our CNC machining factory is equipped with state-of-the-art machinery and skilled technicians, ensuring that your parts are manufactured to the highest standards of quality and precision. Whether you need standard tapped holes or custom-threaded components, we can meet your needs with our advanced CNC prototype machining and custom CNC machining capabilities.

Both tapping and threading can encounter issues that affect the quality of the threads or the integrity of the part:

What to Do with a Broken Tap?

A broken tap can be a significant problem, especially in a blind hole. To remove a broken tap, specialized tools like tap extractors or EDM (electrical discharge machining) may be required. Preventing tap breakage through proper lubrication, correct speed, and careful alignment is key to avoiding this issue.

How to Fix Misaligned Threads?

Misaligned threads can compromise the strength and functionality of a threaded hole. If misalignment occurs, re-tapping the hole with a slightly larger tap or using a thread repair insert can correct the issue. In some cases, the hole may need to be re-drilled and tapped to ensure proper alignment.

How to Prevent Thread Damage During Tapping?

To prevent thread damage during tapping, use the correct tap size and type, apply cutting fluid to reduce friction, and avoid excessive force when turning the tap. Ensuring that the tap is properly aligned with the hole is also critical to prevent cross-threading and other forms of damage.

What is the Difference Between a Threaded and Tapped Hole?

A threaded hole refers to any hole with internal threads, while a tapped hole specifically refers to a hole that has been threaded using a tap. Both terms are often used interchangeably, but tapping refers specifically to the process of creating the threads.

Can a Tap Repair a Stripped Thread?

A tap can sometimes be used to clean up or repair slightly damaged threads, but for severely stripped threads, a thread insert or a larger tap may be needed to restore the hole's functionality.

What are the Processes for Tapping and Threading?

Tapping involves cutting threads into a pre-drilled hole using a tap, while threading generally refers to creating threads on a rod or bolt using a die or threading on a lathe. Both processes are essential in CNC machining for creating threaded connections.

How Do You Make a Threaded Hole on a CNC Machine?

To make a threaded hole on a CNC machine, first drill the hole to the appropriate size, then use a tapping tool or thread mill in the CNC machine to cut the threads. The CNC machine will precisely control the depth and pitch of the threads to ensure accuracy.

What are the Common Hole Types Used in Machining?

Common hole types include blind holes, through holes, countersunk holes, and tapped holes. Each type serves a specific purpose in assembly and fastening applications, with tapped holes being the most common for threaded connections.

Why Use Blind Tapped Holes When Machining?

Blind tapped holes are used when the hole must not pass completely through the material, often to maintain the integrity of the opposite side of the workpiece or to ensure a clean, finished appearance.

What is the Tapping Process for Blind Hole Tapping?

Blind hole tapping involves using a bottoming tap to cut threads to the full depth of the hole. Care must be taken to avoid bottoming out the tap, which can cause breakage or damage to the threads.

What is the Difference Between Cutting Taps and Forming Taps?

Cutting taps remove material to create threads, while forming taps create threads by deforming the material. Forming taps are generally stronger and create threads with higher load-carrying capacity.

What is the Minimum Number of Threads for a Threaded Hole?

The minimum number of threads for a threaded hole depends on the application and the material. Generally, 5-7 full threads are considered sufficient for most applications, but more threads may be required for higher load-carrying capacity.

How Deep Can Thread Tapping Be?

Thread tapping depth depends on the tap size and the material being machined. For blind holes, tapping depth is limited by the hole depth, while through holes can be tapped to any depth as long as the tap can pass through the material.

How to Cut Threads with a Tap?

To cut threads with a tap, start by drilling a hole to the appropriate size. Insert the tap into the hole, ensuring it is perpendicular to the surface, and turn it clockwise to cut the threads. Use cutting fluid to reduce friction and back the tap out periodically to clear chips.

This comprehensive guide provides detailed insights into tapping and threading, helping you understand the differences, similarities, and factors to consider when choosing between these two essential CNC machining processes. Whether you are involved in high-volume production or custom CNC machining, mastering tapping and threading will enhance your manufacturing capabilities and the quality of your CNC machining parts.