15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

221 |

Published by VMT at Jan 07 2024

221 |

Published by VMT at Jan 07 2024

Common Thread Issues in CNC Machined Aluminum Parts and Solutions

Introduction

In the realm of CNC machining, aluminum alloy parts are widely used due to their lightweight, high strength, and excellent machining properties. However, post-machining, issues with threads can arise, potentially affecting the assembly and performance of the parts. This article delves into common thread problems in CNC-machined aluminum parts and proposes corresponding solutions.

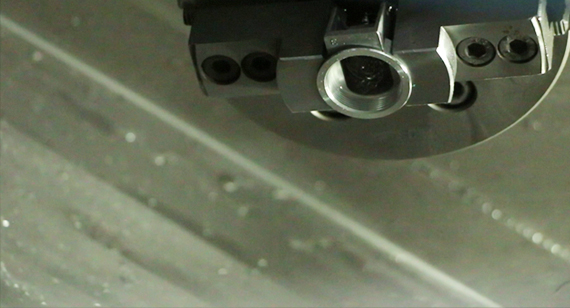

Common Thread Issues in CNC Machined Aluminum Parts

Thread Damage: During the machining process, factors such as tool wear, improper cutting parameters, or inadequate cooling can lead to scratches, tears, or burrs on the surface of threads. These damages not only impact the aesthetics of the part but may also reduce assembly accuracy and lifespan.

Thread Loosening: Due to cutting forces, some threads may experience loosening, affecting their intended fastening capability. In assembly or use, these loose threads may undergo further wear, leading to performance degradation.

Thread Accuracy Problems: Thread accuracy encompasses parameters such as pitch length, major diameter, and thread angle. Design flaws in tools, improper cutting path planning, or inaccurate control of cutting parameters during machining can result in subpar thread accuracy. This affects thread interchangeability, subsequently diminishing part performance.

Heat Treatment Issues: Aluminum alloy materials are prone to thermal deformation during machining. Improper control during heat treatment may cause deformation in the threaded portion, impacting assembly and performance.

Solutions and Optimization Measures

Optimize Tool Selection: Choose suitable tool materials and geometrical parameters based on part material and machining requirements to minimize tool wear and cutting forces. For easily machinable materials like aluminum alloys, consider using hard alloy or diamond tools. Ensure the sharpness of tool edges to reduce friction and heat generation during cutting.

Optimize Cutting Parameters: Precisely control cutting processes by adjusting parameters such as cutting speed, feed rate, and cutting depth. Select appropriate combinations of cutting parameters based on part material and machining requirements to achieve excellent surface quality and higher machining efficiency. Additionally, set up the proper use of coolant to reduce temperature rise during cutting.

Control Machining Processes: Develop rational machining processes to ensure stability and consistency during thread machining. Use suitable tools and cutting parameters for rough and finish machining stages to minimize internal stress and thermal deformation. Strictly control cutting depth and feed rate during semi-finish and finish machining to ensure thread accuracy and surface quality.

Quality Inspection and Control: Strengthen the quality inspection process, rigorously checking thread surface quality, dimensional accuracy, and assembly performance. Utilize high-precision measuring equipment and methods to promptly identify and address quality issues in threads. Establish a robust quality feedback mechanism for traceability and handling of non-conforming products.

Optimize Heat Treatment Processes: Considering the susceptibility of aluminum alloys to deformation, optimize heat treatment parameters such as heating temperature, holding time, and cooling rate. Adjust these parameters to minimize deformation during heat treatment, ensuring the stability of the threaded portion. Employ appropriate post-heat treatment measures, such as artificial aging or natural aging, to eliminate residual internal stresses.

Integrate Advanced Technologies: With the continuous development of CNC machining technology, introducing advanced machining equipment and methods is crucial for improving thread machining quality. For example, using five-axis machining centers for intricate thread machining or employing CAM software for precise toolpath planning and simulation. These advanced technologies enhance machining accuracy and efficiency, reducing the impact of human factors on quality.

Personnel Training and Standardized Operations: Strengthen training and management for operators to ensure proficiency in CNC machine operation skills and adherence to safety standards. Through regular training and assessments, enhance the skill levels and sense of responsibility of operators. Establish and enforce strict machine tool maintenance systems to ensure machines are in good working condition.

Maintenance and Care: Enhance maintenance and care for CNC machines, regularly checking machine accuracy and wear of key components. Timely replace severely worn tools and fixtures, adjust machine geometry parameters and motion parameters to maintain machine stability and accuracy. Through regular maintenance, extend the service life of CNC machines, improving machining quality and efficiency.

Environmental Control: Maintain a clean and suitable temperature and humidity environment for machining, crucial for thread machining quality. Regularly clean the machine and surrounding areas to avoid damage to tools and workpieces caused by dust, iron filings, and other debris. Adjust workshop environmental temperature and humidity based on weather conditions to minimize the influence of thermal expansion and contraction on part accuracy.

Continuous Improvement and Innovation: Encourage enterprises to pursue technological innovation and process improvement continually. Explore new methods, processes, and materials to enhance thread machining quality and efficiency. Through collaboration with research institutions and universities, introduce advanced technologies and achievements, driving ongoing improvement and development. Establish effective incentive mechanisms to encourage employees to propose improvement ideas, fostering active participation in quality improvement.

Conclusion

This article has addressed common thread issues in CNC-machined aluminum parts and provided solutions and optimization measures. By comprehensively focusing on aspects such as tool selection, cutting parameter optimization, machining process control, quality inspection and control, heat treatment process optimization, advanced technology integration, personnel training, maintenance, environmental control, and continuous improvement and innovation, CNC-machined aluminum parts' thread quality and performance can be effectively improved, reducing the probability of issues and enhancing overall production efficiency and product quality. In the future, as CNC machining technology continues to advance and its application areas expand, thread machining technology will become more refined and specialized. Therefore, enterprises need to stay updated on the development trends of new technologies and processes, promptly introducing and applying advanced technologies suitable for their production needs to maintain a competitive edge and meet market demands.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!