15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

240 |

Published by VMT at Dec 25 2023

240 |

Published by VMT at Dec 25 2023

Scale and Challenge: Why 40 Precision Machined Parts Challenge Small CNC Machining Shops

In the manufacturing industry, CNC machining has become a key technology for precision parts manufacturing. However, for small CNC machining factories, when a set of products contains 40 precision machined parts, they will face a series of technical and resource challenges. This article will explore this problem in depth, analyze the reasons and propose corresponding solution strategies.

1. Technical Challenges

Complexity and precision requirements: As the number of precision machined parts in a product increases, so does the complexity of the overall manufacturing process. Each part needs to meet high-precision and high-consistency requirements, which is a huge technical challenge for small processing plants.

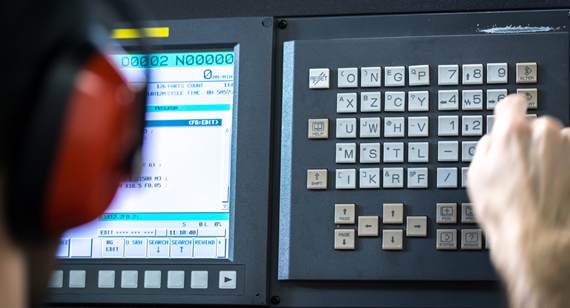

Equipment Capabilities and Limitations: CNC machine tools in small job shops may have limitations in size, accuracy, and functionality. When faced with a large number of parts requiring high precision, these machine tools may not be able to meet the processing needs, resulting in low production efficiency or unstable quality.

Process flow and programming: A set of 40 precision-machined parts requires meticulous process design and complex CNC programming. This requires the CNC machining factory to have a highly qualified technical team and rich experience to ensure that the manufacturing process of each part is accurate.

2. Resource Challenges

Human resources: As the number of parts increases, the number of operators, technical guidance and quality inspection personnel required will also increase accordingly. For small processing plants, there may be a shortage of human resources.

Capital resources: Purchasing and maintaining high-performance CNC machine tools, cutting tools and other production resources requires significant capital investment. Small processing plants may not be financially able to do so, limiting their production capabilities.

Supply chain management: Multiple precision parts in a set of products may require multiple raw materials and complex supply chain management. This requires processing plants to have efficient supply chain management capabilities to ensure the supply and quality of raw materials.

3. Solution strategy

Technology upgrading and R&D: In order to cope with technological challenges, small processing plants should focus on technology upgrading and R&D. Invest in high-performance CNC machine tools to improve equipment accuracy and functionality. At the same time, we will strengthen technical team building and improve employee skill levels to adapt to more complex manufacturing needs.

Process optimization and standardization: Reduce the complexity of the manufacturing process through process optimization. Promote standardized operations to ensure that the manufacturing process of each part is stable and controllable. In addition, an advanced production management system is adopted to improve production efficiency and quality control levels.

Resource integration and cooperation: Facing resource challenges, small processing plants should actively seek external cooperation and resource integration. Establish long-term cooperative relationships with suppliers to ensure stable supply and quality of raw materials. At the same time, we cooperate with other small processing plants or enterprises in professional fields to achieve resource sharing and technical exchanges to jointly enhance competitiveness.

Focus on core competencies: In order to avoid diverting resources and energy due to the pursuit of diversification, small processing plants should clarify their core competencies and focus on developing areas of expertise. By focusing on a specific field or product type, we can improve technical depth and processing precision to better meet market demand.

Continuous training and talent cultivation: Talent is an important driving force for enterprise development. Small processing plants should focus on employee training and talent development, improve the skill level of existing talents, and attract more high-quality talents to join. By continuously enriching the talent pool, we provide a strong talent guarantee for enterprise development.

4. Conclusion

Faced with the challenge of a set of products containing 40 precision-machined parts, small CNC processing factories need to comprehensively optimize and upgrade technology, resources, and processes. Through continuous improvement and innovation, we will improve our competitiveness and adaptability to cope with the increasingly fierce market competition environment. Only in this way can small processing plants find room for survival and development amidst scale and challenges, and contribute to the development of the manufacturing industry.

Looking for the right precision CNC machining factory VMT

VMT is a 14-year factory specializing in precision CNC machining parts, located in Shenzhen, China. It has passed ISO9001 and 16949 certification and obtained 11 patents.

VMT also has imported 5-axis CNC machines, CNC turning machines, automatic lathes, a total of 100 CNC machines. The precision can reach 0.005mm, and has built its own reliability laboratory, with 3D projector, 2D projector, CCD inspection, height, hardness tester and other testing equipment.

In addition, there are 2 SQE engineers and 6 engineers with 20 years of experience, free of charge to assist customers with design and structural optimization, using a variety of processes, and costs can be reduced by up to 30%.

The company has set up 12 inspection processes to strictly control quality from DFM review, pre-production, IQC, first piece inspection, process inspection to final inspection to ensure that the yield rate reaches 99.98%, and the cost is also reduced. And VMT have a self-built material warehouse, stocking 40+ types of materials, with stable prices, and can provide material reports.

The business has now grown to cover 62 countries and various fields around the world, and has long-term cooperation with GE, Haas, Volkswagen, Allegionp and other companies. Successfully completed 10000+ projects. Our products cover different fields such as medical, automotive, agriculture, 3C electronics, control systems, petroleum and industry.

Welcome your visit and looking forward to manufacturing CNC machining parts for you.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!