15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

187 |

Published by VMT at Oct 12 2022

187 |

Published by VMT at Oct 12 2022

First of all, CNC machining is suitable for most precision parts CNC machining in robotics, aviation, navigation, automotive, medical, industrial and other fields. CNC machining has high precision, fast efficiency and stable quality. As the saying goes, anything that flies in the sky, runs on the ground, or swims in the water can be created!

The CNC machining center is controlled by numerical control programming, and the machining program is programmed in advance and put into the CNC operating system. It is processed by the operator according to the process. Machine tools are further divided into ordinary CNC machining centers, 3-axis, 4-axis, 5-axis and compound machining centers.

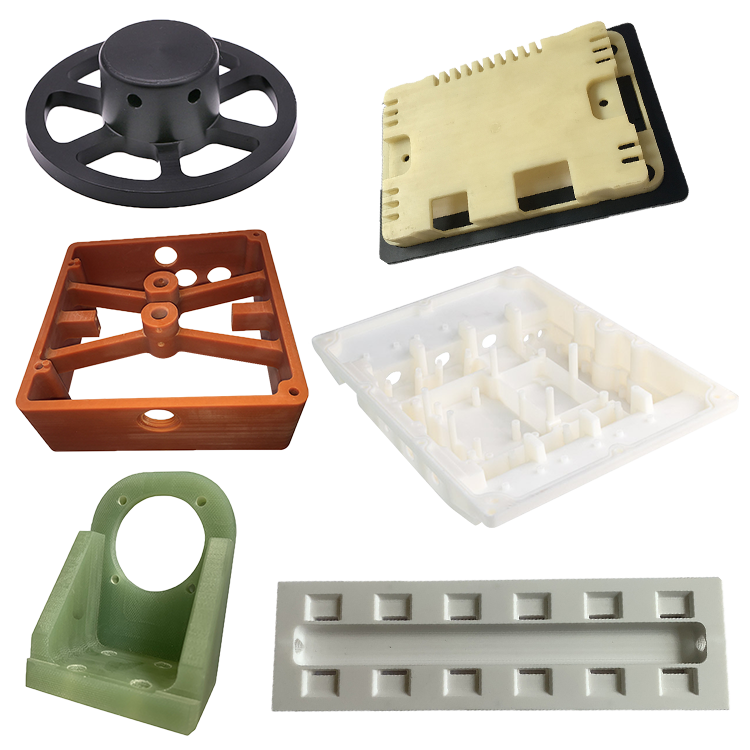

The CNC machining center can perform multi-axis linkage machining of precision parts with complex structures, and can also make metal prototypes or plastic prototypes for R&D companies for new products in the R&D stage for reference.

The CNC machining center can process aluminum profiles, stainless steel, magnesium alloys, acrylic, ABS and various plastic raw materials. High compatibility. The process can be divided into fine turning, fine boring, fine milling, fine grinding, grinding and post-machining.

Fine turning and fine boring: Many precision light alloy parts use this method to CNC process the parts (aluminum alloy or magnesium alloy), and the coordinate accuracy can reach ±2 microns.

Fine milling: used for CNC machining of complex-shaped aluminum or beryllium alloy structural parts, relying on the precision of the guide rail and spindle of the machine tool to obtain high mutual position accuracy, using a carefully ground diamond cutter head for high-speed milling to obtain precise precision. mirror.

Fine grinding: used for CNC machining of shaft or hole parts. Most of these parts are made of hardened steel with high hardness.

Grinding: Use the principle of mutual grinding of mating parts to selectively process the irregular convex parts on the machined surface, and the accuracy can be as high as ±0.01mm.

VMT is a professional CNC machining manufacturer with 13 years of experience in precision custom CNC machining production. With professional CNC machining and production equipment, through a complete quality control system, CNC machining factories that provide one-stop services such as CNC machining, CNC milling, CNC turning, die casting, extrusion, surface treatment, etc.

The above is just a summary of the VMT CNC machining factory. If you want to know more about CNC machining, you can contact us: inquiry@vimetal.com.cn to negotiate with us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!