15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

129 |

Published by VMT at Aug 19 2022

129 |

Published by VMT at Aug 19 2022

The production and processing process of the CNC machining factory is an important document to guide the manufacturing. It plays a great role in ensuring the CNC machining quality of the parts and meeting the requirements specified in the design drawings. At the same time, it can improve efficiency and reduce costs on the basis of ensuring the quality of CNC machining.

CNC machining itself has high CNC machining accuracy, and metal CNC machining has distinctive advantages for high precision, complex, and small batch CNC machining production; general shaft, rod, round type small batch CNC machining production, special precision requirements or Small batch CNC machining production has relatively advantages.

The basic principles and specific measures to improve the strength of CNC machined parts are: select high-strength raw materials, carry out heat treatment for raw materials to increase strength and reduce internal stress, control the CNC machining process to reduce or remove microscopic defects, etc.; Loads; properly related to the structure of CNC machined parts to reduce stress concentrations, etc.

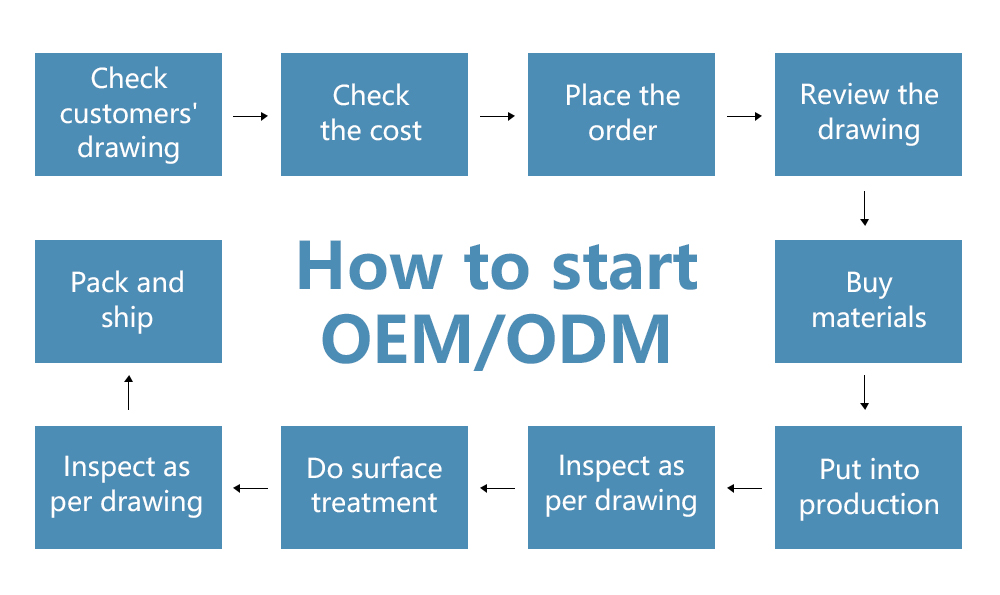

What are the production steps of the CNC machining factory:

1. Analyze the design drawings and assembly of CNC machined parts, and understand the use and performance of the finished product.

2. Review the process, which is the process arrangement to review the precision and quality of the CNC machining of the later products, whether it is scientific and reasonable.

3. Determine the blank material and CNC machining method, according to the role of CNC machining parts in the product, the size of the parts, the process characteristics of the parts material and the number of CNC machining parts.

4. Formulate the process route, including: CNC machining method, CNC machining sequence, etc.

5. Determine the cutting allowance for each process.

The above is just a summary of the production and machining process of CNC machined parts by VMT CNC machining factory. If you have detailed information, you can contact us: inquiry@vimetal.com.cn to discuss with us.

VMT13 years custom precision CNC machining parts, metal, plastic prototype CNC machining factory. Its business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields. 40+ materials and 15+ surface finish options available with free service design, project reviews and DFM analysis. To ensure the quality of parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save 15% of time cost and communication cost for you!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!