15 years one-stop China custom CNC machining parts factory

276 |

Published by VMT at Aug 10 2024

276 |

Published by VMT at Aug 10 2024

Taps are essential tools in the field of CNC machining for producing internal threads. This article aims to provide a comprehensive overview of tap types, features, applications, and selection methods, serving as a detailed reference for experts and operators in CNC machining. Readers will gain insights into the basic structure of taps, suitable scenarios for different types of taps, standard tap markings, usage precautions, and common troubleshooting tips. This knowledge will help users master tap usage techniques, improve machining efficiency, and enhance product quality.

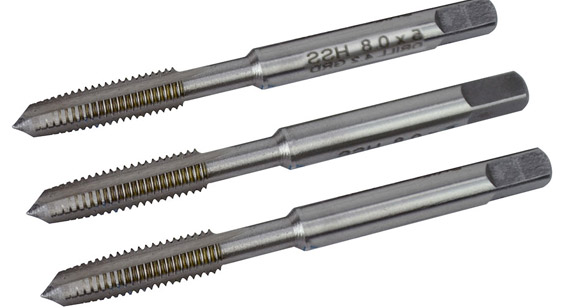

A thread tap is a specialized tool used for creating internal threads by cutting into a workpiece through rotational and feeding movements. A tap typically consists of a shank, flutes, lands, cutting face, and other components, with its design and material selection directly influencing the machining performance and tap longevity.

Main Body

Cutting Section: The primary part of the tap, including the cutting edges and cutting face, which performs the cutting operation. The cutting section is usually tapered to distribute the cutting load across multiple teeth. This section often contains incomplete thread portions for cutting the thread.

Guide Section: Located just after the cutting section, featuring complete threads that refine the thread and guide the tap axially to ensure thread accuracy and shape.

Shank

Shank: The gripping and driving part of the tap, typically paired with a tap wrench to transmit torque and control rotation. The shank is often designed in a square or hexagonal shape for easy gripping and stability.

Other Components

Flutes: Grooves along the tap’s axis that hold and remove chips generated during cutting, preventing clogging and ensuring effective cutting. The number and shape of flutes affect cutting efficiency and chip evacuation.

Lands: The area behind the cutting edge that provides strength and rigidity, supporting the cutting edge and preventing vibration and deflection during cutting.

In summary, the primary components of a tap include the cutting section (with the cutting face and edges), guide section, shank, and flutes. These parts work together to complete the task of internal thread machining. While different types of taps (such as hand taps and machine taps) may vary in specific structure and parameters, the basic principles remain similar.

Taps can be classified based on various criteria, including shape, usage environment, and specifications. Each tap type has specific application scenarios and advantages, making the selection of the right tap crucial for improving machining efficiency and product quality.

Hand Taps: Suitable for manual threading operations, typically used for small-batch, low-precision threading. Simple in structure and easy to operate but relatively low in efficiency.

Taper Taps: Primarily used for measuring parameters such as hole diameter, thread profile, and taper to ensure machining accuracy. Common types include Morse taper taps and Jarno taper taps.

Automatic and Semi-Automatic Machine Taps: Designed for CNC machining centers and automated production lines, enabling efficient and precise threading. Fully automatic machine taps can operate unattended, further enhancing productivity.

Thread Taps: One of the most common tap types, widely used in CNC centers for drilling blind holes. They offer fast processing speeds, high accuracy, and good chip evacuation, suitable for threading various materials.

Other Tap Types:

Extended Taps: Used for deep-hole machining, allowing for deeper cuts.

Bent Shank Taps: Suitable for threading at special angles, such as on inclined planes or angled holes.

Fixed Bolt Taps: Designed for threading in specific situations where bolts are used.

Spiral Flute Taps: Improve chip evacuation through spiral flute design, enhancing machining quality and efficiency.

Bottoming Taps: Designed for blind holes, suitable for threading to the bottom of the hole.

Combination Drill and Tap: Combines drilling and threading functions to increase processing efficiency.

Solid Carbide Taps: Made of carbide, offering high hardness and wear resistance, suitable for threading difficult-to-machine materials.

Spiral Point Taps: The pointed design aids in cutting into the workpiece, ideal for precision machining.

Interrupted Thread Taps: Used for threading where intermittent threads are required.

Pipe Taps: Specifically for pipe threads, ensuring connection tightness.

Forming or Roll Taps: Create threads through cold forming, improving thread surface quality and strength.

Standard tap markings indicate key information such as the tap’s specifications, material, and accuracy, helping users select the appropriate tap for machining.

Nominal Size: The basic size parameter of the tap, indicating the nominal diameter or pitch of the thread it can produce.

Thread Form Symbol: Indicates the type of thread the tap produces, such as metric, inch, or unified threads.

Tap Material: The material of the tap, which directly affects its machining performance and life. Common materials include HSS (High-Speed Steel), HSS-E (Cobalt-Added High-Speed Steel), and carbide.

Pitch Diameter Limits: The range of pitch diameters the tap can produce, used to control the machining tolerance and thread accuracy.

Pitch Diameter Limits (Thread Diameter < 1")

L1 = Basic to Basic Minus .0005

H1 = Basic to Basic Plus .0005

H2 = Basic Plus .0005 to Basic Plus .0010

H3 = Basic Plus .0010 to Basic Plus .0015

H4 = Basic Plus .0015 to Basic Plus .0020

H5 = Basic Plus .0020 to Basic Plus .0025

H6 = Basic Plus .0025 to Basic Plus .0030

Different types of taps are required in machining to address varying needs. Different taps offer varying efficiency, precision, and material adaptability. For example, extended taps are needed for deep-hole machining; carbide taps might be selected for difficult-to-machine materials; and forming or roll taps might be preferred in situations demanding high precision and surface quality. Additionally, different industries and applications have unique thread requirements, such as precision, strength, and corrosion resistance, making the choice of the right tap type crucial.

Using a tap for threading requires precise control and careful operation, involving several steps such as clamping the workpiece, selecting appropriate cutting parameters, drilling, and performing the tapping operation.

Clamping Process:

Before machining, ensure the workpiece is securely clamped on the machine to prevent movement or vibration during machining. This helps maintain machining accuracy and tap longevity.

Precautions:

Lubrication: Apply an appropriate lubricant to the tap and workpiece surface before tapping to reduce friction and heat generation, extend tap life, and improve machining quality.

Cutting Speed: Select an appropriate cutting speed based on the tap type and material properties to avoid poor cutting performance or tap damage.

Feed Rate: Control the feed rate to ensure a smooth cutting process, avoiding overload or insufficient cutting force.

Drilling Process:

Before tapping, drilling is usually required to ensure the hole’s depth and diameter meet the threading requirements. Choose a suitable drill bit and control drilling speed and feed rate.

Tapping Operation:

Starting: Gently rotate the tap into the workpiece until the cutting edge contacts the workpiece surface.

Stable Feed: Maintain a stable feed rate and evenly rotate the tap until the desired thread depth is achieved.

Retracting: After reaching the preset depth, slowly reverse the tap and retract it from the workpiece to avoid damaging the thread.

Choosing the right tap type involves multiple factors, including workpiece type, tap material, hole type, and cutting speed.

Workpiece Type: Select the appropriate tap type based on the material, shape, and size of the workpiece. For example, use carbide taps for difficult-to-machine materials, or extended taps for deep-hole machining.

Tap Material: The tap material directly affects its machining performance and longevity. Choose the appropriate tap material based on the hardness and toughness of the machining material.

Hole Type: Different types of holes (such as through holes, blind holes, inclined holes, etc.) require different types of taps. For example, blind hole machining may require taps with a relief groove for easier retraction.

Cutting Speed: Choose the appropriate cutting speed based on machine performance and machining requirements. Too fast a speed may lead to excessive cutting forces and increased tap wear, while too slow a speed may reduce machining efficiency.

Using charts to find tap sizes is a quick and effective method that helps users quickly select the appropriate tap size based on the workpiece’s thread specifications.

Standard Formula for Calculating Drill Sizes:

Standard formulas can be used to calculate the required drill size based on the thread specifications and machining requirements. These formulas typically consider the nominal diameter, pitch, and cutting allowance of the thread.

Tap Size Charts:

Many manufacturers and suppliers provide tap size charts that allow users to find the corresponding tap size based on the workpiece’s thread specifications. These charts typically include parameters such as nominal diameter, pitch, pitch diameter limits, and more.

| Tap size | Major Diameter (mm) | mm per thread | Drill Size (mm) |

| M1.6 × 0.35 | 1.6mm | 0.35 | 1.25mm |

| M2 × 0.4 | 2mm | 0.4 | 1.6mm |

| M2.5 × 0.45 | 2.5mm | 0.45 | 2.05mm |

| M3 × 0.5 | 3mm | 0.5 | 2.5mm |

| M3.5 × 0.6 | 3.5mm | 0.6 | 2.9mm |

| M4 × 0.7 | 4mm | 0.7 | 3.3mm |

| M5 × 0.8 | 5mm | 0.8 | 4.2mm |

| M6 × 1 | 6mm | 1 | 5mm |

| M8 × 1.25 | 8mm | 1.25 | 6.8mm |

| M8 × 1 | 8mm | 1 | 7mm |

| M10 × 1.5 | 10mm | 1.5 | 8.5mm |

| M10 × 1.25 | 10mm | 1.25 | 8.8mm |

| M12 × 1.75 | 12mm | 1.75 | 10.2mm |

| M12 × 1.25 | 12mm | 1.25 | 10.8mm |

| M14 × 2 | 14mm | 2 | 12mm |

| M14 × 1.5 | 14mm | 1.5 | 12.5mm |

| M16 × 2 | 16mm | 2 | 14mm |

| M16 × 1.5 | 16mm | 1.5 | 14.5mm |

| M18 × 2.5 | 18mm | 2.5 | 15.5mm |

| M18 × 1.5 | 18mm | 1.5 | 16.5mm |

| M20 × 2.5 | 20mm | 2.5 | 17.5mm |

| M20 × 1.5 | 20mm | 1.5 | 18.5mm |

| M22 × 2.5 | 22mm | 2.5 | 19.5mm |

| M22 × 1.5 | 22mm | 1.5 | 20.5mm |

| M24 × 3 | 24mm | 3 | 21mm |

| M24 × 2 | 24mm | 2 | 22mm |

| M27 × 3 | 27mm | 3 | 24mm |

| M27 × 2 | 27mm | 2 | 25mm |

In summary, taps are vital tools in CNC machining, with various types and wide-ranging applications. Choosing the right tap type and using it correctly is crucial for improving machining efficiency and product quality. By understanding the basic structure, types, standard markings, usage methods, and precautions associated with taps, users can better master tap usage techniques and apply them in actual production. We also recommend professional CNC machining service providers, such as VMT, to offer high-quality services and support for your CNC thread machining projects.

Why Should You Lubricate Taps Before Tapping?

Lubricating taps before tapping reduces friction and heat generation during the cutting process, lowering the risk of tap wear and breakage while improving machining quality and efficiency.

What Are the Most Common Tap Types?

The most common tap types include hand taps, machine taps (including automatic and semi-automatic), thread taps, extended taps, bent shank taps, and more. Each type has its characteristics and application scenarios.

What is the Difference Between Hand Taps and Machine Taps?

Hand taps are generally used for manual threading operations and are simple in structure and operation. Machine taps, on the other hand, are designed for automated machining centers, enabling efficient, precise, and high-volume threading operations.

How Do You Choose the Right Tap Material?

Choosing the right tap material depends on the hardness and toughness of the workpiece material, as well as the machining environment. Common tap materials include high-speed steel (HSS), cobalt-added high-speed steel (HSS-E), and carbide, each offering different levels of wear resistance and machining performance.

What is the Difference Between Taps-3 and Taps 4?

Taps-3 and Taps-4 usually refer to different series of taps, and their differences may lie in material, precision, applicable range, and other aspects. The specific differences need to be determined based on the product manual or information provided by the manufacturer.

What Are the Standard Types of Thread Taps?

The standard types of thread taps include metric thread taps, inch thread taps, and unified thread taps. Each standard type follows the specifications of their respective countries or international organizations, such as ISO (International Organization for Standardization), DIN (German Industrial Standard), ANSI (American National Standards Institute), and others. These standards detail the geometry, tolerances, marking methods, and testing requirements of threads.

What Types of Thread Taps Are Used for Bronze?

For soft metal materials like bronze, commonly used thread taps include general high-speed steel taps (HSS), cobalt-added high-speed steel taps (HSS-E), and some carbide taps. Since bronze is relatively soft, selecting these materials ensures efficient machining while avoiding excessive cutting or damage to the workpiece. Additionally, due to the specific nature of bronze, the cutting angle and edge shape of the tap may need to be considered to ensure the quality of the machined threads.

What Are the Types of Metal Thread Taps?

There are many types of metal thread taps, including but not limited to the following:

High-Speed Steel Taps (HSS): Suitable for machining most metal materials, offering high hardness and wear resistance.

Cobalt-Added High-Speed Steel Taps (HSS-E): Enhanced with cobalt to improve heat and wear resistance, suitable for machining hard-to-cut metals.

Carbide Taps: Made from carbide material, offering extremely high hardness and wear resistance, suitable for machining high-hardness, high-wear metals.

Coated Taps: Feature a coating on the surface to improve wear resistance, lubrication, or corrosion resistance, thereby enhancing machining performance and tap life.

Special-Shaped Taps: Such as extended taps or bent shank taps, suitable for processing holes in specific shapes or positions.

Can Thread Taps Be Used to Re-Tap Existing Holes?

Thread taps can generally be used to re-tap existing holes, but several factors should be considered:

Condition of the Hole: If the original hole is damaged or has burrs, cracks, etc., it may need to be repaired or re-drilled before re-tapping to ensure thread quality.

Selection of the Tap: When re-tapping, choose a tap that matches the thread specifications of the original hole and ensure that the cutting edges of the tap are sharp and undamaged.

Cutting Parameters: Adjust the cutting speed, feed rate, and other cutting parameters when re-tapping to suit different machining conditions and requirements.

Lubrication and Cooling: Ensure adequate lubrication and cooling during the re-tapping process to reduce friction and heat generation, protecting both the tap and the workpiece.

In summary, by selecting the appropriate tap type, adjusting cutting parameters, and paying attention to machining details, it is possible to successfully re-tap existing holes to meet various machining needs.