15 years one-stop China custom CNC machining parts factory

792 |

Published by VMT at Aug 09 2024

792 |

Published by VMT at Aug 09 2024

Screen printing, also known as silk screen printing, is a widely used printing technique that employs a mesh screen as a stencil. Ink is forced through the mesh by a squeegee onto various surfaces. Due to its flexibility, cost-effectiveness, and high-quality print results, screen printing is extensively applied across numerous industries. This article will delve into the screen printing process, types, advantages, and applications, and will compare it to other printing methods, aiming to provide CNC machining professionals and industry experts with a comprehensive understanding.

The screen printing process involves several meticulous steps from design to finished product, each impacting the final quality.

Step 1: Design Sketch

Before starting screen printing, a design sketch must be completed. Designers use professional design software to create the desired pattern, ensuring it meets client needs and expected outcomes. This stage is crucial as it lays the foundation for the subsequent printing work.

Step 2: Select and Prepare the Mesh Screen

Based on the design, select the appropriate mesh screen material (e.g., nylon, polyester) and mesh count. The quality of the mesh screen directly affects the print's fineness and clarity. The preparation process also involves cleaning and coating the screen with a photosensitive emulsion for later exposure and stencil creation.

Step 3: Expose the Screen

Place the designed film on the mesh screen and expose it to UV light or another light source. During exposure, the pattern on the film projects onto the photosensitive emulsion, creating corresponding shadow areas.

Step 4: Wash Out Emulsion and Create the Stencil

After exposure, place the screen in a developer solution to wash away the unexposed emulsion, leaving a clear outline of the pattern. After this step, the stencil on the screen is ready.

Step 5: Prepare for Screen Printing

Install the prepared mesh screen on the printing machine, adjusting the distance and angle between the screen and the substrate. Choose suitable ink and a squeegee based on the substrate material and pattern requirements.

Step 6: Print the Design

Activate the printing machine, using the squeegee to evenly spread the ink across the screen surface. The ink passes through the pattern areas of the screen and transfers onto the substrate, forming the desired pattern and text.

Step 7: Transfer Ink onto the Item

During printing, maintain consistent pressure and speed on the squeegee to ensure uniform ink distribution and pattern clarity. Adjust the ink's viscosity and drying properties to avoid printing defects.

Step 8: Product Drying and Inspection

After printing, move the substrate to a drying area for natural drying or curing. During drying, regularly inspect the product surface to ensure the ink is fully cured and not peeling off.

Step 9: Heat Curing and Finalization

For certain substrates like PET and PP, additional heat curing may be necessary to enhance ink adhesion and durability. After heat curing, the screen printing process is complete.

Screen printing requires a series of specialized equipment to support efficient and high-quality printing.

Printer and Film: Output design patterns on film for use as exposure templates.

Mesh Screens: Key components that carry the photosensitive emulsion and stencil pattern.

Inks: Selected based on substrate material and printing requirements to ensure optimal print quality and adhesion.

Squeegees: Used to evenly spread ink across the screen, with hardness and shape adjusted according to printing needs.

Printing Machines: Hold the screen and substrate, providing a stable printing environment and precise control.

Conveyor Dryers: Accelerate substrate drying, improving production efficiency.

Screen printing can be categorized into several types based on printing methods and requirements.

Grayscale Printing: Achieves grayscale variation by adjusting ink concentration and screen exposure time, suitable for prints requiring gradation and delicacy.

Spot Color Printing: Uses specific ink colors for printing, suitable for prints needing specific color effects or brand image.

CMYK (Four-Color Printing): Mixes cyan, magenta, yellow, and black inks to achieve full-color printing, widely used for various color prints.

Duotone Printing: Uses two ink colors to create unique visual effects through color overlay and contrast.

Halftone Printing: Achieves halftone effects by adjusting screen exposure time and ink concentration, presenting varying depths of color within the pattern.

Simulated Process Printing: Uses special inks and techniques to simulate complex visual effects like metallic textures, patterns, or special gloss, often used in packaging, advertising, and art.

Screen printing has distinctive advantages and some limitations.

Advantages:

Streamlined Process: Can print directly on various materials without complex pre-treatment, simplifying production.

Versatility: Suitable for paper, plastic, metal, glass, and more, providing rich decoration and labeling solutions.

Durable Design: Cured screen printing inks adhere well and are durable, resisting daily use and environmental factors.

Efficiency: Capable of fast, efficient printing for large-scale production.

Vivid Ink Colors: Produces vibrant, high-quality visuals, enhancing product appeal.

Disadvantages:

High Setup Cost: Initial investment in equipment, screen preparation, and ink mixing is significant.

Increased Cost with More Colors: Products requiring multiple colors incur higher costs due to additional screens and ink preparation.

Screen printing's versatility and advantages make it applicable across various industries.

Electronics: Marking and labeling on circuit boards and electronic components for traceability and safety.

Textiles: Printing patterns and text on clothing and fabrics, enhancing design elements and visual appeal.

Glass and Ceramics: Decorative printing on glassware and ceramic items, increasing artistic value and market competitiveness.

Window Decals and Displays: Printing advertisements and promotional materials on glass windows and display boards to attract customer attention.

Apparel Design: Printing patterns, text, or brand logos on apparel fabrics to meet consumer demand for personalization and fashion.

Medical Devices: Printing warning labels and usage instructions on medical equipment and packaging for safe usage.

Decals and Stickers: Producing decorative decals and stickers for stationery, toys, household items, and more.

Balloons: Printing patterns and text on balloons for festive and celebratory events.

Product Labels: Printing product labels, barcodes, and information for easier management and traceability.

Signage: Creating various signs and safety markers for public guidance and warnings.

Displays: Printing protective and decorative layers on display screens and touch screens for protection and aesthetics.

Consumer Goods: Printing on packaging to enhance product image and market appeal.

Textile Fabric Design: Complex pattern and texture printing on fabrics for unique designs and textures in the fashion industry.

Sports Products: Printing brand logos and patterns on sports shoes and clothing to enhance brand recognition and market attractiveness.

Screen printing and digital printing are distinct techniques with differences in setup time, cost, color output, print quantity, ink adhesion, and durability.

Setup Time and Cost: Screen printing requires screen preparation and ink mixing, taking longer and being costlier initially. Digital printing, on the other hand, can print directly from computer files, with shorter setup time and lower cost.

Color Output: Screen printing delivers high saturation and vibrant colors, while digital printing offers precise color matching and reproduction through color management systems.

Quantity: Screen printing is suitable for large-scale production, while digital printing is ideal for small batches and diverse production.

Ink Adhesion and Durability: Screen printing inks adhere well and are durable. Digital printing's ink adhesion and durability vary based on ink types and substrate materials.

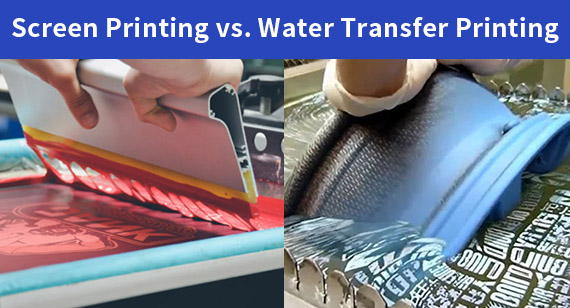

Screen printing and water transfer printing differ in printing principles, material application, and cost-effectiveness. Water transfer printing uses water pressure to transfer patterns onto substrates, suitable for complex surfaces and materials difficult to print directly. Screen printing uses a squeegee to press ink onto substrates, with broader material compatibility and higher print precision.

Screen printing and water transfer printing are two common printing technologies with significant differences in various aspects. Below is a detailed comparison of both:

Process Principles

Screen Printing: This method utilizes a mesh screen as a stencil, with a photosensitive emulsion to create a pattern on the screen. During printing, ink is poured at one end of the screen, and a squeegee applies pressure to the inked areas while moving across the screen. The ink is pushed through the mesh openings onto the substrate, creating the printed image. Screen printing is known for its vibrant colors, clear patterns, waterproof, lightfast, and abrasion-resistant properties.

Water Transfer Printing: This technique uses water as a medium to transfer patterns onto the surface of objects through an intermediary carrier (special paper or plastic film). There are two types of water transfer printing: water decal transfer and water immersion transfer. The former is mainly used for transferring text and photo patterns, while the latter is used for complete surface transfers on products. Water immersion transfer printing employs a water-soluble film to carry the pattern, which is then uniformly transferred onto the product surface through water pressure.

Material Application

Screen Printing: This method is highly adaptable and can print on various materials, including paper, fabric, leather, glass, ceramics, metal, and plastic.

Water Transfer Printing: Suitable for printing on the surfaces of items with different shapes and materials, such as automotive interiors, rims, wood, helmets, and mobile phone cases. It is characterized by its good stereoscopic effect, clear and realistic patterns, rich colors, and resistance to fading, especially suitable for curved surfaces.

Cost-Effectiveness

Screen Printing: Costs vary depending on materials and process complexity, but overall, screen printing offers good cost-effectiveness for large-scale production.

Water Transfer Printing: The production cost is relatively low, especially for small, fashionable handicrafts and products requiring high-temperature and long-lasting images. The effect achieved by water transfer printing equipment is unparalleled by other simple printing methods. However, specific costs depend on product size, complexity, and market pricing.

Color

Screen Printing: Produces vibrant colors and clear patterns, capable of printing a wide range of colors.

Water Transfer Printing: Delivers rich colors and realistic patterns with a strong stereoscopic effect, capable of presenting various visual effects.

Time

Screen Printing: Offers a relatively fast printing speed, dependent on the machine and process complexity. Automated screen printing can achieve 1-30 cycles per minute.

Water Transfer Printing: Also has a relatively fast speed, generally not exceeding 10 minutes per cycle, with no mold costs. However, jigs may be needed to process multiple products simultaneously to reduce time costs.

Quantity

Screen Printing: Suitable for small to large batch production needs.

Water Transfer Printing: Also applicable to various production quantities but may have an advantage in small batch or customized production.

Durability

Screen Printing: The ink bonds tightly to the substrate surface, providing high durability, abrasion resistance, lightfastness, and waterproof properties.

Water Transfer Printing: After transfer and protective coating application, it also offers good durability, with patterns resistant to fading or peeling.

Conclusion

Screen printing and water transfer printing exhibit clear differences in process principles, material applications, cost-effectiveness, color, time, quantity, and durability. The choice of printing method should be based on specific needs and product characteristics.

While screen printing has many benefits, other processes like laser engraving and etching can achieve similar logo effects with different characteristics and display effects.

Laser Engraving:

Laser engraving or laser marking uses a high-energy laser beam to engrave or mark the surface of materials. Unlike screen printing, laser engraving directly ablates the material surface to form patterns or text. Its advantages include high precision, permanent marking, and environmental friendliness.

Etching:

Etching uses chemical or electrochemical methods to create patterns or text on the material surface. Wet etching uses chemical solutions to corrode the material surface, while dry etching uses plasma or laser. Etching offers depth control and detail precision, suitable for materials like metals, glass, and ceramics.

Screen printing, a mature and widely applied printing technology, offers unique advantages and value across various fields. However, for specific applications requiring high precision, durability, or special material handling, processes like laser engraving and etching also provide effective alternatives. Understanding and mastering these different techniques help CNC machining professionals meet client needs and enhance product quality and market competitiveness.

What are the differences between laser engraved logos, etched logos, and screen printed logos?

Laser engraved logos are created by ablating the material surface with a laser, offering high precision and durability. Etched logos use chemical or electrochemical methods to corrode the material surface, achieving depth and detail. Screen printed logos use ink pressed onto the material surface, providing vibrant colors and versatility.

What are some possible drawbacks to using screen printing?

Screen printing can have high setup costs, especially for multi-color prints, and may not be as cost-effective for small production runs. The process can also be time-consuming due to the need for screen preparation and ink mixing.

How does a screen printing press work?

A screen printing press holds the mesh screen and substrate in place. The squeegee spreads ink across the screen, pressing it through the stencil areas to transfer the design onto the substrate. Adjustments can be made to the press to control print quality and consistency.

What are some alternatives to screen printing?

Alternatives to screen printing include digital printing, laser engraving, and etching. Each method offers different advantages in terms of setup time, cost, color output, precision, and material compatibility.

What are some things that can be screen printed?

Screen printing can be applied to a wide range of materials, including textiles, paper, plastic, metal, glass, ceramics, and more. Common items include clothing, promotional products, packaging, electronics, and signage.