15 years one-stop China custom CNC machining parts factory

1010 |

Published by VMT at Aug 04 2024

1010 |

Published by VMT at Aug 04 2024

Titanium, known for its high strength, low density, and corrosion resistance, is extensively used across industries such as aerospace, medical, automotive, marine engineering, and jewelry. However, due to its high hardness and silver-gray appearance, machining and polishing titanium becomes a challenging task. This article will delve into the steps, types, benefits, applications, and surface treatment methods of titanium polishing, providing comprehensive guidance for experts and practitioners in the field of CNC machined parts manufacturing.

Titanium metal can indeed be polished, requiring appropriate polishing processes and equipment. Polishing titanium not only enhances its aesthetics but also improves its surface properties, such as conductivity, corrosion resistance, and wear resistance. Polished titanium is widely used in high-end manufacturing fields, becoming an important means to enhance product quality and added value.

Polishing titanium alloy is a specialized process that requires special attention due to its different physical properties compared to many other metals. Here are some key points about polishing titanium alloy:

Thermal Conductivity: Titanium alloy has relatively low thermal conductivity, meaning that coolant is needed during cutting or polishing to prevent localized overheating.

Hardness: The high hardness of titanium alloy may require greater force and more durable polishing tools in the polishing process.

Polishing Methods: Mechanical polishing methods are commonly used for titanium alloy samples, requiring control over pressure and speed. For high-purity titanium, electrolytic polishing may be necessary to avoid the generation of defective layers.

Chemical Polishing: Chemical polishing is a method of flattening and polishing through the oxidation-reduction reaction of metal in a chemical medium, suitable for complex structural titanium alloy polishing, but the process parameters are difficult to control.

Polishing Wheel Speed: When polishing titanium alloy, the speed of the polishing wheel is generally 900-1800 m/min to avoid burnishing and micro-cracks on the titanium surface.

Polishing Effects: Polishing can improve the surface quality and aesthetics of titanium alloy, as well as its corrosion resistance and biocompatibility.

Polishing Materials: For polishing titanium alloy, it is best to use ultra-hard abrasives with good thermal conductivity, such as diamond and cubic boron nitride.

Polishing Process: Includes steps such as surface pretreatment, grinding, polishing, sandblasting, cleaning, and surface treatment.

Polishing Difficulty: Due to the low elastic modulus of titanium alloy, poor rigidity, and susceptibility to deformation, there is a certain difficulty in polishing.

Purpose of Polishing: Polishing titanium alloy can not only enhance the appearance of products but also improve corrosion resistance, improve cleanability and sterility, reduce friction, and increase electrical conductivity.

In general, titanium alloy can be polished, but it requires professional technology, tools, and materials to achieve high-quality polishing effects.

The tools and equipment required for polishing titanium are diverse, including but not limited to polishing pads, grinding wheels, brushes, sisal, polishing wheels, etc. These tools and equipment play an important role in different stages of titanium polishing to ensure the smooth progress of the polishing process and the achievement of the polishing effect.

Polishing Pads

Polishing pads are a common tool in mechanical polishing, typically made from soft and durable materials. They work in conjunction with polishing compounds to smooth the surface of titanium by removing burrs and oxide layers through rotation and friction.

Grinding Wheels

Grinding wheels are more frequently used in the rough processing stage, using the high-speed rotation of abrasive grains to grind the titanium surface and remove larger defects and unevenness. The choice of grinding wheel depends on the hardness of the material being processed and the required processing accuracy.

Brushes

Brushes are used in the cleaning and deburring stage to remove tiny particles and dirt from the titanium surface, preparing it for subsequent polishing processes. The material and hardness of the brush should be selected based on processing requirements.

Polishing Wheels

Polishing wheels are an indispensable tool in the polishing process, usually made from soft and delicate materials. They combine with polishing compounds to finely polish the titanium surface through rotation and friction, achieving a mirror-like effect.

Titanium polishing refers to the process of removing rough layers, oxide skins, and scratches from the surface of titanium metal through a series of physical or chemical methods, making the surface smooth, flat, and bright. Polished titanium not only looks beautiful but also has better surface properties and corrosion resistance.

Methods for polishing titanium are diverse, including mechanical polishing, electrolytic polishing, vibration polishing, precision polishing, diamond polishing, plasma polishing, titanium alloy rough/medium/fine cutting polishing, and magnetorheological finishing technology. Each method has its unique advantages and scope of application, and choosing the right polishing method is crucial for achieving the desired polishing effect.

Mechanical Polishing

Overview: Mechanical polishing is one of the most common methods for titanium polishing. It uses mechanical equipment and abrasives to rub and grind the titanium metal surface, removing burrs and oxide layers.

Process: Mechanical polishing typically includes three stages: rough grinding, medium grinding, and fine grinding. In the rough grinding stage, coarse grinding wheels or sandpapers are used to remove larger defects and unevenness; in the medium grinding stage, finer grinding wheels or sandpapers further refine the surface; in the fine grinding stage, polishing pads and polishing compounds are used for detailed polishing until the required surface finish is achieved.

Electrolytic Polishing

Electrolytic polishing is a method that uses electrochemical reactions to remove the oxide skin and scratches from the surface of titanium metal. During the electrolysis process, the titanium metal acts as the anode and undergoes an oxidation reaction in the electrolyte, forming a uniform oxide film on the surface. This oxide film is then removed through dissolution to achieve a polishing effect. Electrolytic polishing has the advantages of fast polishing speed and high surface finish, but it is important to control the concentration of the electrolyte and the current density to avoid corrosion and damage.

Process:

Electrolytic polishing utilizes the principles of electrolysis to create chemical reactions on the metal surface, thereby achieving a smoothing and polishing effect. Before electrolytic polishing, prepare the electrolyte, anode, and cathode, and clean the workpiece. Then, place the workpiece in the electrolysis tank, connect the power supply, and adjust parameters such as current density, electrolysis time, and temperature. During electrolysis, a current is generated between the anode and cathode, dissolving the metal surface oxides, thus achieving polishing. After polishing, clean the workpiece to remove residual electrolyte and metal powder.

Vibration Polishing

Vibration polishing involves placing workpieces in a vibration polishing machine, where the combined action of abrasives and polishing liquid polishes the workpiece surface through vibration. During the polishing process, it is necessary to select the appropriate abrasives and polishing liquid and control the vibration time and intensity. Vibration polishing is suitable for batch processing of small parts or workpieces with complex shapes and can effectively remove surface burrs and oxide layers.

Precision Polishing

Precision polishing is usually a further refinement process based on mechanical polishing. It uses finer polishing materials and lower polishing pressures to achieve a higher surface finish. Precision polishing is often used for workpieces that require extremely high surface quality, such as precision instrument parts.

Diamond Polishing

Diamond polishing uses diamond particles as abrasives for polishing. Due to the extreme hardness of diamonds, they are suitable for polishing high-hardness materials. Diamond polishing can be divided into mechanical and chemical-mechanical types; the former mainly uses diamond grinding wheels or grinding powder for grinding, while the latter combines chemical corrosion to improve polishing efficiency.

Plasma Polishing

Plasma polishing is a method that utilizes active free radicals in a plasma to react chemically with the surface atoms of the workpiece, achieving material removal and surface polishing. This method has the advantages of being pollution-free, causing no mechanical deformation or damage, and can achieve extremely high surface quality. Plasma polishing is usually carried out in a vacuum chamber and requires precise control of various process parameters.

The rough, medium, and fine cutting polishing of titanium alloy correspond to the rough grinding, medium grinding, and fine grinding stages of mechanical polishing. Rough cutting is mainly used to remove a large amount of burrs and uneven parts on the workpiece surface; medium cutting further refines the surface roughness; fine cutting achieves a mirror-like effect. Each stage requires the selection of appropriate polishing materials and process parameters.

Magnetorheological finishing technology is a method that uses the rheological effect of magnetorheological fluid under the action of a magnetic field to polish the workpiece surface. This technology has the advantages of high polishing accuracy and good surface quality, especially suitable for polishing complex shapes and precision workpieces. During the polishing process, the magnetorheological fluid forms a flexible polishing mold under the action of a magnetic field, contacts and polishes the workpiece surface through grinding action.

These eight methods each have their characteristics and application scope. In practical applications, they should be selected and optimized according to factors such as the material, shape, and surface quality requirements of the workpiece.

Step 1: Degreasing and Cleaning Process

Before polishing, it is essential to degrease and clean the titanium surface to remove oils, dirt, and oxide layers. This step is crucial for achieving a high-quality polish. Degreasing and cleaning can be done chemically or mechanically, depending on the processing requirements and the degree of surface contamination.

Step 2: Grinding Process

Grinding is a key step before polishing, where tools like grinding wheels and sandpaper are used to rough grind and medium grind the titanium surface, removing larger defects and unevenness. During the grinding process, it is important to control the grinding pressure and speed to avoid damaging the titanium surface.

Step 3: Polishing Process

Polishing is the key step to achieving a mirror-like finish. In this stage, tools and equipment such as polishing pads, polishing wheels, and polishing compounds are used to finely polish the titanium surface. The pressure and duration of the polishing process must be controlled, along with the type and concentration of the polishing compound, to ensure an even, delicate, and bright surface. The choice of polishing wheel should be based on the initial state of the titanium surface and the desired level of smoothness.

Step 4: Final Finishing

After polishing, the titanium surface must be thoroughly cleaned to remove any residual polishing compounds and fine particles. Post-cleaning, surface quality checks can be performed, such as observing surface smoothness with a microscope and measuring surface roughness, to ensure the polishing effect meets the requirements. Finally, as needed, apply anti-rust treatment or a protective coating to protect the polished titanium surface from corrosion and damage.

Titanium polishing can be divided into various types of surface treatment, such as rough polishing, medium polishing, fine polishing, and mirror polishing, according to different processing needs and effect requirements. Each type has its unique surface effect and scope of application.

Rough Polishing

Rough polishing is primarily used to remove larger defects and unevenness on the surface of titanium metal, such as casting defects and welding marks. Through rough polishing, the flatness of the titanium metal surface can be significantly improved, laying the foundation for subsequent fine polishing.

Medium Polishing

Medium polishing further refines the surface of the titanium metal on the basis of rough polishing, removing smaller scratches and rough spots. After medium polishing, the surface of the titanium metal is smoother, but still retains a certain level of gloss.

Fine Polishing

Fine polishing is a key step in achieving a high-quality surface finish. In this stage, fine polishing processes and tools can remove minor defects and roughness from the surface of the titanium metal, making it as smooth as a mirror. The surface of titanium metal after fine polishing has excellent visual effects and surface performance.

Mirror Polishing

Mirror polishing represents the highest level in the polishing process, requiring a surface finish and reflective effect like that of a mirror. Mirror polishing necessitates the use of high-precision polishing equipment and techniques, and it takes a long time of fine polishing and repeated inspection to achieve the ideal surface effect. The surface of titanium metal after mirror polishing has extremely high aesthetics and surface performance and is widely used in high-end manufacturing fields.

Benefits of Polishing Titanium Alloy Parts

Enhanced Aesthetics: Polished titanium alloy parts have a smooth and bright surface, which is highly visually appealing.

Improved Electrical Conductivity: Polishing removes surface oxides and contaminants, enhancing the electrical conductivity of the titanium alloy.

Optimized Resistance: The smooth surface reduces fluid or frictional resistance, improving the performance of titanium alloy parts in specific applications.

Extended Service Life: Polishing minimizes microcracks and scratches on the surface of titanium alloy parts, enhancing their corrosion and wear resistance, thereby extending their service life.

Drawbacks of Polishing Titanium Alloy Parts

High Cost: The polishing process requires high-precision equipment and craftsmanship, and the polishing process is time-consuming, making the cost relatively high.

Technical Skill Requirements: Polishing demands proficient operational skills and extensive experience; otherwise, it can easily cause damage to the titanium alloy parts or fail to achieve the desired polishing effect.

Polished titanium parts, known for their excellent performance and aesthetic appeal, are widely used across various industries. Here are some of the main application areas:

Aerospace Industry

In the aerospace field, polished titanium parts are used to manufacture critical components of aircraft and rockets, such as engine blades, landing gear, and fuselage structural parts. These polished titanium parts are not only visually appealing but also possess excellent corrosion resistance and high-strength properties, meeting the demands of extreme working conditions.

In the medical sector, polished titanium parts are extensively used for manufacturing medical devices and implants due to their good biocompatibility and corrosion resistance, such as surgical instruments, artificial joints, and dental implants. The smooth surface of these parts minimizes irritation and injury to the human body, enhancing the success rate of surgeries and patient comfort.

In automotive manufacturing, polished titanium parts are used for engine components, exhaust systems, and body decorative parts. Polished titanium parts not only enhance the luxury and grade perception of vehicles but also offer excellent corrosion resistance and high-temperature performance, contributing to the extended lifespan and improved performance of cars.

Marine Engineering

In the marine engineering sector, polished titanium parts are utilized in the construction of desalination equipment, offshore oil extraction equipment, and ship structural parts. These parts can withstand the corrosive and erosive effects of seawater, ensuring the stable operation of equipment in harsh marine environments.

In the jewelry industry, polished titanium metal is used to craft high-end jewelry items such as rings, necklaces, and bracelets. The mirror-like smooth surface of polished titanium jewelry exhibits a unique metallic luster and texture, making it a symbol of fashion trends.

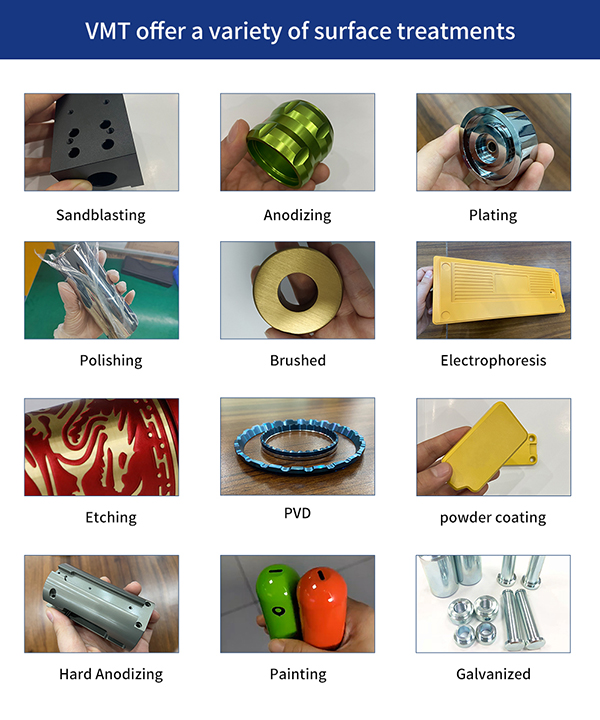

In addition to polishing, titanium alloys can be modified through various other surface treatment methods to meet different usage requirements. Here are some common surface treatment options for titanium alloys:

Anodizing

Anodizing is an electrochemical surface treatment technique that forms an oxide layer on the surface of titanium alloys. This oxide layer offers excellent corrosion and wear resistance, protecting the titanium alloy surface from environmental erosion.

Electroplating

Electroplating is the process of depositing a layer of metal or alloy onto the surface of titanium alloys. It can alter the surface color, glossiness, and hardness of titanium alloys, enhancing their decorative and functional properties.

Brushing

Brushing is a mechanical surface treatment technique that creates straight or crisscross textures on the surface of titanium alloys. This technique endows titanium alloy parts with a unique visual effect, enhances the feel and aesthetics, and also helps improve the surface's wear resistance and fingerprint-preventing performance.

Powder Coating

Powder coating is a dry, solvent-free paint that adheres to the surface of titanium alloys through methods like electrostatic spraying and forms a uniform coating after heating and curing. Powder coatings offer excellent corrosion resistance, wear resistance, and decorative effects, providing a variety of color and texture options for titanium alloy parts while meeting environmental requirements.

VMT, as a professional CNC machining service provider, is dedicated to offering high-quality custom polishing services for titanium CNC machined parts. Equipped with advanced CNC machining equipment and a team of specialized technicians, we can precisely process and polish according to our clients' specific requirements and blueprints, ensuring each part meets or exceeds the anticipated quality standards. Whether it's a simple polishing task or a complex surface texturing process, VMT provides comprehensive solutions to meet a variety of customer needs.

Titanium polishing, an essential method for enhancing the surface quality and performance of titanium alloy parts, is widely applied across various fields. By selecting the appropriate polishing techniques and process parameters, combined with advanced CNC machining technology, precise control and optimization of the titanium alloy part surfaces can be achieved. This article has provided a detailed introduction to the steps, types, benefits, applications, and surface treatment methods of titanium polishing, offering comprehensive guidance and reference for experts and practitioners in the field of CNC machined parts. Moreover, we recommend choosing a professional CNC machining service provider like VMT to ensure the receipt of high-quality custom polished titanium CNC machined parts services.

How to clean titanium rings?

Cleaning titanium rings is relatively straightforward. You can use mild soapy water or a specialized jewelry cleaner. Soak the ring in the cleaning solution, gently scrub the surface with a soft-bristled brush, then rinse thoroughly with water and dry with a clean cloth.

How to clean titanium jewelry?

The cleaning method for titanium jewelry is similar to that for titanium rings, using mild soapy water or jewelry cleaner. Avoid using harsh chemicals or abrasive items that could scratch the surface and damage the luster of the titanium jewelry.

How to clean titanium alloy exhaust pipes?

Cleaning titanium alloy exhaust pipes is more complex and requires selecting the appropriate cleaning method based on the specific situation. Generally, high-pressure water jets or specialized cleaners can be used for washing. For stubborn stains or carbon buildup, professional cleaning tools or chemical agents may be necessary. However, take care to avoid damaging the surface of the titanium alloy during the cleaning process.

How to polish a titanium metal watch band?

Polishing a titanium metal watch band requires the use of professional polishing equipment and tools. The general steps include degreasing and cleaning, grinding, polishing, and final finishing. During the polishing process, control the polishing pressure and time, and select the appropriate polishing compound to ensure an even, delicate, and bright surface effect.

How to polish a titanium alloy bicycle frame?

Polishing a titanium alloy bicycle frame requires meticulous craftsmanship and professional equipment. Start with degreasing and cleaning, then use grinding wheels or sandpaper for rough and medium grinding to remove surface imperfections. Next, use polishing pads and compounds for fine polishing until the desired surface smoothness is achieved. Throughout the process, control the polishing pressure and speed to avoid damaging the frame.

What is the best polishing compound for titanium?

The best polishing compound for titanium depends on the specific polishing needs and surface condition. Generally, for rough polishing, you can choose coarser compounds such as aluminum oxide or silicon carbide; for fine polishing, finer compounds such as diamond paste or silicone polishing agents are required. Additionally, chemical polishing agents or electrolytic polishing solutions can be used as needed.

Can you polish out scratches on titanium?

Yes, scratches on titanium can be removed through polishing. However, it's important to note that the depth and size of the scratches will affect the difficulty and effectiveness of the polishing. For shallow scratches, fine polishing can remove them; deeper scratches may require localized repair or reprocessing.

Can you electrolytically polish titanium?

Yes, electrolytic polishing is an effective method for polishing titanium. It uses electrochemical reactions to form a uniform oxide layer on the titanium surface and removes this layer along with minor surface imperfections through dissolution, achieving a polished effect. Electrolytic polishing has the advantages of fast polishing speed and high surface smoothness but requires careful control of electrolyte concentration and current density to avoid corrosion and damage.

What is the best method for polishing a titanium bicycle frame?

The best method for polishing a titanium bicycle frame depends on the initial condition of the frame and the desired surface effect. Generally, a combination of mechanical polishing and electrolytic polishing can be used for comprehensive treatment. Start with degreasing and cleaning, then use grinding wheels or sandpaper for rough and medium grinding; follow with electrolytic polishing or fine mechanical polishing as needed; and finally, clean and apply anti-rust treatment. Throughout the process, control the polishing pressure and speed and select the appropriate polishing agents and equipment.