15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

155 |

Published by VMT at Dec 03 2023

155 |

Published by VMT at Dec 03 2023

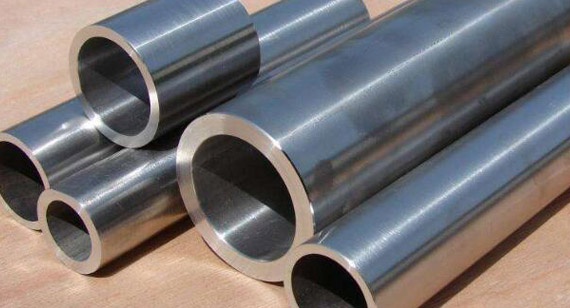

Advanced Titanium CNC Machining Materials for Aerospace and Defense Applications

In the realm of aerospace and defense, where precision and durability are paramount, the choice of materials for CNC machining plays a crucial role. Titanium, with its exceptional properties, stands out as a high-performance material for these industries. Here are some advanced titanium alloys commonly used in CNC machining for aerospace and defense applications:

Ti-6Al-4V (Grade 5 Titanium):

Known for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility, Ti-6Al-4V is a widely used titanium alloy in aerospace components such as aircraft structures, engine components, and missile systems.

Ti-6Al-2Sn-4Zr-2Mo (Beta-C Titanium):

Beta-C titanium alloy exhibits a good balance of strength and toughness. It is employed in aerospace applications, including landing gear components, due to its ability to withstand high stress and fatigue.

Ti-3Al-2.5V (Grade 9 Titanium):

Grade 9 titanium strikes a balance between strength, formability, and weldability. It finds application in aircraft hydraulic systems, airframe components, and other aerospace structures.

Ti-15V-3Cr-3Al-3Sn (Beta-21S):

Beta-21S is a beta titanium alloy known for its high strength and excellent creep resistance at elevated temperatures. It is utilized in aerospace components subjected to high-stress conditions.

Ti-10V-2Fe-3Al (Beta-C Alloy):

Beta-C alloy offers a combination of high strength, toughness, and corrosion resistance. It is employed in aerospace applications where a lightweight yet robust material is essential.

Ti-5Al-5Mo-5V-1Cr-1Fe (IMI 550):

IMI 550 is a high-strength titanium alloy suitable for critical aerospace components, including landing gear, due to its excellent fatigue resistance and fracture toughness.

Ti-6Al-2Sn-4Zr-6Mo (Ti 6246):

Ti 6246 exhibits superior high-temperature strength and is used in aerospace engine components, such as compressor blades and discs.

Ti-6Al-2Sn-4Zr-2Mo-0.1Si (Ti 6242):

Ti 6242 offers improved fracture toughness and is utilized in aerospace applications requiring enhanced damage tolerance.

These advanced titanium alloys undergo CNC machining processes to create intricate and precise components for aircraft, spacecraft, defense systems, and other critical applications. The combination of titanium's unique properties and CNC machining precision makes these materials integral to the success of aerospace and defense technologies.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!