15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

377 |

Published by VMT at May 15 2024

377 |

Published by VMT at May 15 2024

Introduction

In the field of CNC machining parts manufacturing, titanium and steel, as two common metal materials, are widely used in various industrial projects due to their unique physical and chemical properties. This article provides a comprehensive overview of titanium and steel, and delves into a detailed comparison of their differences in terms of elemental composition, weight, hardness, elasticity, durability, tensile yield strength, common applications, and pricing, aiming to assist readers in making the right choice for their projects.

Overview of Titanium

Titanium is a lightweight, high-strength metal with excellent corrosion resistance and biocompatibility. It belongs to the transition metal elements, with an atomic number of 22 and a relative atomic mass of 47.867. Titanium is widely distributed in nature, mainly in the forms of ilmenite, rutile, and titanite. Due to its unique properties, titanium has extensive applications in aerospace, medical devices, chemical industry, and other fields.

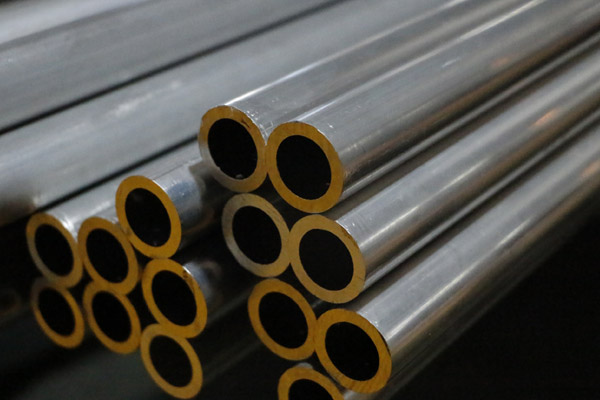

Overview of Steel

Steel is an iron-carbon alloy with a carbon content ranging from 0.02% to 2.11%. It is one of the most widely used metal materials in human history. The chemical composition of steel can be adjusted according to the requirements to meet the performance requirements in different fields. Steel, with its low cost, reliable performance, and wide applicability, has become an indispensable material in construction, manufacturing, and daily life.

Titanium vs. Steel: 8 Major Differences between Two Popular Metal Choices

Elemental Composition:

Titanium is primarily composed of titanium elements, with high purity, while steel is an alloy composed of iron and carbon, with its chemical composition adjustable as needed.

Weight:

Titanium is a lightweight metal, with a density only about half of that of steel, giving titanium an advantage in applications requiring weight reduction.

Hardness:

While steel exhibits high hardness, titanium also boasts high strength, especially excelling in tensile, compressive, and bending strength.

Elasticity:

Steel has good elasticity and can withstand deformation to some extent without rupturing, whereas titanium has poorer elasticity but better toughness.

Durability:

Titanium demonstrates excellent corrosion resistance and wear resistance, maintaining a longer service life in harsh environments, while steel's corrosion resistance and wear resistance are relatively poor.

Tensile Yield Strength:

Titanium has a high tensile yield strength, capable of withstanding large tensile stresses without plastic deformation, whereas steel's tensile yield strength is relatively lower.

Common Applications:

Titanium finds wide applications in aerospace, medical devices, and chemical industries, while steel is widely used in construction, bridges, automobiles, and ships, among others.

Pricing:

Titanium's price is relatively high due to its rarity and extraction costs, while steel's price is relatively low, making it the preferred material in many applications.

Comparison of Titanium and Steel — Advantages and Disadvantages of Each Metal

Advantages of Titanium:

Lightweight: Titanium's low density reduces the weight of components.

High Strength: Titanium exhibits high tensile, compressive, and bending strength.

Excellent Corrosion Resistance: Titanium can resist corrosion from various chemicals.

Good Biocompatibility: Titanium is widely used in the medical field due to its harmlessness to the human body.

Advantages of Steel:

Low Cost: Steel's raw material price is low, reducing production costs.

Wide Range of Applications: Steel is widely used in various fields due to its strength and reliability.

Good Machinability: Steel can be shaped and processed through various methods.

Disadvantages of Titanium:

High Price: Titanium's raw material price is high, increasing the cost of products.

Difficulty in Machining: Titanium's high hardness makes it prone to wear and heat during machining.

Difficulty in Welding: Titanium welding requires high precision technology and equipment.

Disadvantages of Steel:

Susceptible to Rust: Steel is prone to rust in humid environments and requires anti-rust treatment.

High Density: Steel has a high density compared to other materials, increasing the weight of components.

Poor Wear Resistance: Steel has relatively poor wear resistance and is prone to wear under high loads or friction.

Choosing Your Best Partner

When choosing between titanium and steel as project materials, you need to consider the project's requirements, budget, and performance requirements comprehensively. If your project requires lightweight, high-strength, and corrosion-resistant materials, then titanium may be the better choice. However, if your project has strict cost requirements and does not require exceptionally high performance, then steel may be more suitable.

As experts in the field of CNC machining parts manufacturing, we recommend collaborating with professional CNC machining factories when selecting materials. They can provide professional advice and solutions based on your specific requirements, ensuring you choose the most suitable material for your project.

Conclusion: Titanium vs. Steel

Titanium and steel, as two common metal materials, have extensive applications in the field of CNC machining parts manufacturing. They each have unique advantages and disadvantages, suitable for different application scenarios. When choosing materials, you need to consider the project's requirements, budget, and performance requirements comprehensively to make the right choice. Collaborating with professional CNC machining factories can help you choose the most suitable material for your project and ensure the smooth progress of the project.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!