15 years one-stop China custom CNC machining parts factory

334 |

Published by VMT at Jul 14 2024

334 |

Published by VMT at Jul 14 2024

Overview

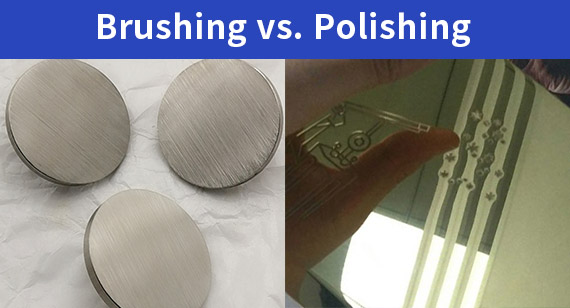

In the field of CNC machined parts manufacturing, surface treatment is a crucial step to enhance product aesthetics, corrosion resistance, and functionality. Brushing and polishing are two common surface treatment techniques, each with unique process characteristics, application advantages, and limitations. This article aims to delve into the differences between brushing and polishing processes, including their definitions, workflows, pros and cons, surface effects comparison, and suitable applications, to help readers make better choices for custom CNC machining projects.

Brushing, also known as satin or matte finish, is a surface treatment technique that creates continuous, parallel fine lines or streaks on a metal surface through mechanical means. This process not only enhances the aesthetic appeal of the metal surface but also hides minor scratches, improving tactile feel and slip resistance. In CNC machined parts, brushing is commonly used on materials such as aluminum alloys, stainless steel, and copper, and is widely applied in electronic product housings, automotive interiors, and furniture decoration.

Polishing is the process of removing the rough surface layer of metal through physical or chemical methods, making it smooth like a mirror. The polishing process significantly improves the surface smoothness and flatness of products, enhances reflectivity, and provides a luxurious and elegant visual appeal. In the CNC machining field, polishing is often used as the final surface treatment for precision parts, jewelry, and high-end tableware to achieve a perfect appearance.

Brushing is a metal processing technique involving the compression of metal through a die under external force to achieve the desired shape and size. This process not only improves the appearance of the metal but also enhances surface quality by hiding minor scratches.

The brushing process typically includes the following key steps:

Pre-treatment: Clean the metal surface to remove oil, oxidation layers, and other impurities, laying a good foundation for subsequent processing.

Coarse Brushing: Use coarse-grained brushing tools to initially form rough lines on the metal surface.

Fine Brushing: Switch to fine-grained brushing tools to further refine the lines, achieving the desired texture.

Post-treatment: Clean the surface to remove debris generated during brushing, possibly followed by oxidation, coloring, or other treatments to enhance visual effects.

Final Inspection and Packaging: Perform a final inspection on the brushed and surface-treated metal products to ensure quality standards are met, then package them.

Brushing can produce various types of textures, such as straight lines, random lines, threads, waves, and swirls, which not only have decorative effects but also provide functional benefits like corrosion resistance and hiding mechanical marks and mold defects.

Brushing is widely applied across industries, including but not limited to electronics, home appliances, and automotive sectors. For example, in the electronics industry, brushing is used for smartphone housings and laptop panels; in the home appliance industry, it is used for elevator doors, escalator decorative panels, and kitchen equipment; in the automotive industry, it is used for interior panels.

In the brushing process, it is particularly important to control the drawing speed and temperature to prevent cracks and surface deformation, ensuring product quality. Additionally, the smoothness and overall appearance of the brushed metal surface are also key points of process control.

Polishing is a crucial technology in metal processing and surface treatment, aimed at improving material surface smoothness and appearance, achieving a transition from rough to smooth to mirror-like finishes. The following is a general workflow for the polishing process:

Pre-treatment: Remove oil, rust, and other impurities from the material surface to ensure effective polishing.

Coarse Grinding: Use coarse sandpaper or grinding wheels to initially grind the surface, removing deep scratches and unevenness.

Intermediate Grinding: Gradually use medium-grit sandpaper or grinding wheels to further smooth the surface.

Fine Grinding: Switch to finer sandpaper or grinding wheels to meticulously grind the surface, further reducing surface roughness and preparing for polishing.

Pre-polishing Preparation: Thoroughly clean the ground surface to remove all debris generated from grinding.

Selecting Suitable Polishing Tools: Choose appropriate polishing wheels, polishing compounds, etc., based on the desired polishing effect and material characteristics.

Coarse Polishing: Use coarse polishing compounds for initial polishing, quickly improving surface smoothness.

Intermediate Polishing: Transition to medium-grit polishing compounds to enhance surface smoothness.

Fine Polishing: Use fine polishing compounds for detailed polishing, further eliminating small surface defects.

Mirror Polishing: For surfaces requiring high gloss, perform mirror polishing.

Using Polishing Liquid: Appropriately use polishing liquid during the polishing process to reduce friction heat and improve polishing effects.

Controlling Polishing Speed: Control polishing speed to avoid surface burns from excessive speed or inefficiency from low speed.

Inspecting Polishing Process: Regularly check the polishing effect to ensure the expected surface quality is achieved.

Removing Polishing Marks: After polishing, it may be necessary to remove marks left by polishing tools.

Cleaning and Drying: Thoroughly clean the polished surface to remove all polishing compound residues, then dry.

Quality Inspection: Perform strict quality inspection to ensure surface smoothness meets design and functional requirements.

Surface Treatment: Perform surface treatments as needed, such as coating, coloring, or other surface finishing.

Recording and Feedback: Record process parameters and results for continuous improvement.

Polishing can be applied to various materials, including stainless steel, aluminum, copper, titanium, and some non-metal materials. Different materials and final usage requirements will determine specific polishing steps and materials used.

Advantages:

Enhances product aesthetics with unique texture.

Hides minor surface scratches, improving durability.

Improves tactile feel and slip resistance.

Suitable for various metal materials with flexible processes.

Disadvantages:

Once formed, textures are difficult to completely remove or change.

Not suitable for applications requiring high surface smoothness.

Relatively high processing costs, especially for fine brushing.

Advantages:

Significantly improves surface smoothness and flatness, enhancing reflectivity.

Suitable for precision parts and high-end products requiring high surface quality.

Easy to clean and maintain, retaining long-lasting luster.

Disadvantages:

Polishing may remove excess material, affecting part dimensional accuracy.

Difficult to polish certain materials, such as high-hardness alloys.

Polished surfaces may be too smooth, affecting slip resistance.

Materials: Both are suitable for various metal materials, but specific effects depend on material properties.

Cost: Polishing usually costs more than brushing, especially to achieve mirror effects.

Applications: Brushing is better for anti-slip, anti-fingerprint, or specific texture needs; polishing is ideal for precision products seeking ultimate smoothness and reflectivity.

Process: Brushing forms textures through mechanical friction, while polishing achieves smoothness by removing surface roughness.

Choosing between brushing and polishing should be based on specific product needs, design style, cost budget, and market positioning. For products emphasizing unique textures, slip resistance, and cost-effectiveness, brushing might be the better choice. For precision products seeking superior appearance, high reflectivity, and a luxurious feel, polishing has more advantages.

When choosing a CNC machining manufacturing partner, focus on their technical capabilities, advanced equipment, quality control system, and past project experience. A professional CNC machining factory can provide one-stop services from design consultation, material selection, process planning to final product delivery, ensuring your project is completed on time, within quality standards, and in the desired quantity. By working closely with your partner, you can more accurately assess the applicability of brushing and polishing processes and make the best choice for your project needs.

Brushing and polishing are essential surface treatment techniques in CNC machined parts manufacturing, each with unique process characteristics and application advantages. Understanding and mastering the differences between these two processes will help make more informed choices in custom CNC machining projects.

Is brushed steel better than stainless steel?

There is no definitive answer to this as "better" depends on specific application scenarios and requirements. Brushed steel and stainless steel have their characteristics in terms of material, performance, and appearance. Brushed steel refers to steel that has undergone brushing treatment, enhancing its visual and tactile feel while covering surface defects. Stainless steel is known for its excellent corrosion resistance and strength, widely used in applications requiring high durability and aesthetics. Therefore, if your project demands high corrosion resistance and strength, stainless steel might be the better choice. If the focus is on appearance and slip resistance, brushed steel might meet your needs better.

Will brushed stainless steel rust?

Brushed stainless steel is not prone to rust under normal conditions due to its inherent corrosion resistance. However, it is not entirely immune to rusting. Prolonged exposure to harsh, corrosive environments or surface damage that breaches the protective layer can lead to rust. Therefore, maintaining and cleaning brushed stainless steel regularly and avoiding prolonged exposure to adverse conditions is essential to prevent rust.

What are the advantages of a brushed surface finish?

Brushed surface finishes have several advantages:

Enhances aesthetics with unique texture.

Improves tactile feel and slip resistance.

Hides minor surface scratches, making the product appear flawless.

Increases surface hardness to some extent, improving wear resistance.

Easy to clean and maintain, preventing dust and stains from adhering.

Summary

Whether choosing brushing or polishing, both are vital surface treatment techniques in CNC machined parts manufacturing, each with unique advantages and suitable scenarios. Selection should consider specific product requirements, design styles, cost budgets, and material characteristics. Collaborating closely with reliable CNC machining manufacturing partners ensures high-quality project completion and enhanced customer satisfaction. This article aims to provide valuable insights into the choice between brushing and polishing processes.