15 years one-stop China custom CNC machining parts factory

449 |

Published by VMT at Jul 15 2024

449 |

Published by VMT at Jul 15 2024

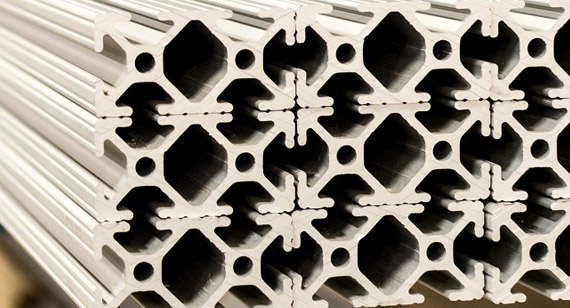

8020 aluminum, also known as 80/20 aluminum or 8020 aluminum profile, is a high-performance aluminum alloy widely used in the CNC machining parts manufacturing field. Its unique chemical composition and physical properties make 8020 aluminum excel in various industrial sectors. This alloy is primarily composed of aluminum, silicon, iron, copper, manganese, magnesium, chromium, and other elements, combined in precise proportions to provide excellent mechanical properties and corrosion resistance.

Mechanical Properties:

8020 aluminum has a high strength-to-weight ratio, making it an ideal choice for industrial applications. Its tensile strength and yield strength are relatively high, allowing it to maintain stable performance under various complex working conditions. Additionally, 8020 aluminum possesses good ductility and malleability, making it easy to form into various shapes and sizes.

Corrosion Resistance:

8020 aluminum performs excellently in acidic, alkaline, and chloride-rich environments, resisting the corrosion of various media. This superior corrosion resistance makes 8020 aluminum widely used in chemical, marine engineering, and other fields.

High-Temperature Performance:

Certain 8020 aluminum alloys (such as UNS NO8020) also exhibit excellent high-temperature performance, maintaining stable chemical stability and mechanical properties in high-temperature environments. This makes it significant in the manufacturing of high-temperature components in aerospace, petrochemical, and power industries.

Machinability:

8020 aluminum is easy to process and shape, obtainable through various methods such as hot and cold processing. Its good machinability not only enhances production efficiency but also reduces manufacturing costs.

Modularity:

8020 aluminum profiles feature modular designs that can be easily assembled into various complex structures. This design simplifies the installation process and enhances structural flexibility and maintainability.

Ease of Assembly and Installation:

8020 aluminum extrusions often use standardized sizes and interfaces, making the assembly and installation process more straightforward and faster. Additionally, its lightweight design reduces the difficulty of transportation and installation.

Aesthetic Appeal:

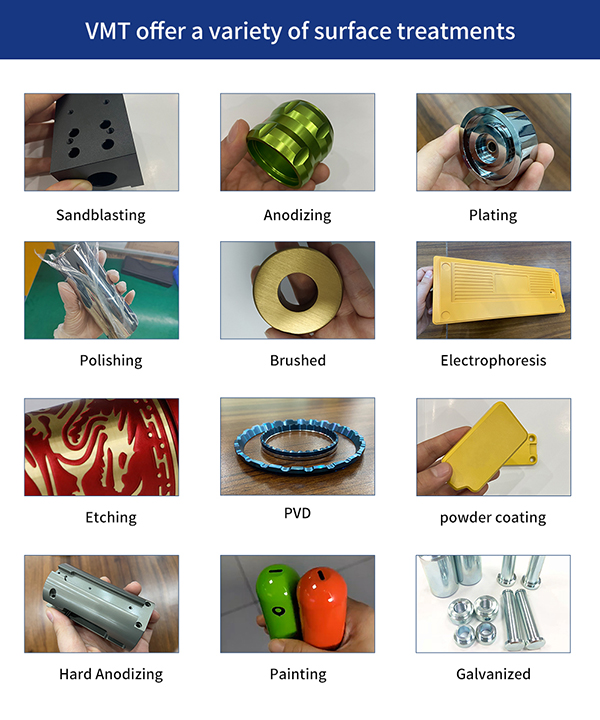

8020 aluminum extrusions have a smooth and flat surface, offering a good visual effect. Appropriate surface treatments (such as anodizing, painting, etc.) can further enhance its aesthetic appeal and durability.

Despite its numerous advantages, 8020 aluminum extrusions have some potential drawbacks. For example, their cost is relatively high, especially for large-scale production projects where cost issues may be more pronounced. Additionally, in some specific conditions, the corrosion resistance of 8020 aluminum may not be as good as certain special alloys.

Excellent Performance: 8020 aluminum possesses high strength, corrosion resistance, high-temperature resistance, and other excellent properties, meeting the demands of various complex working conditions.

Machinability: Its good machinability makes the processing more convenient and efficient, reducing manufacturing costs.

Modular Design: Modular design enhances structural flexibility and maintainability, simplifying the installation process.

Aesthetic Appeal: Appropriately treated 8020 aluminum extrusions have good visual effects, suitable for various applications with high aesthetic requirements.

When selecting 8020 aluminum extrusion materials, it is crucial to consider several key factors:

Cost

Cost is one of the significant factors influencing the choice of materials. It is essential to choose the appropriate material specifications and quantities based on the project's budget and cost requirements.

Structural Integrity

Structural integrity is vital for the success of the project. It is necessary to select the appropriate material thickness, strength, and hardness parameters according to the actual needs of the project to ensure stability and safety.

Material Cost

In addition to the direct material price, the costs of processing, transportation, and installation must also be considered. A comprehensive evaluation of all costs will help in choosing the most cost-effective material solution.

Surface treatment plays an important role in enhancing the material's corrosion resistance and aesthetic appeal. The appropriate surface treatment method (e.g., anodizing, painting) should be chosen based on actual needs, ensuring that the treatment effect meets the project requirements.

8020 aluminum extrusions have a wide range of applications across various fields, including but not limited to:

Industrial Automation: Used in manufacturing various automation equipment and production lines, such as robotic arms, conveyor belts, etc.

Building Automation: Used to construct frameworks and structural components of building automation systems, such as frames for LEED building projects.

Aerospace: Used to manufacture high-temperature components like combustion chambers and turbine blades of engines.

Petrochemical: Used in refining equipment, chemical reactors, and high-temperature pipelines.

Marine Engineering: Used in seawater desalination equipment, seawater coolers, and offshore oil extraction equipment.

8020 aluminum extrusions come in various types and series, including fractional series and metric series. Different types of extrusions have different sizes and specifications suitable for different application scenarios.

Fractional Series

Fractional series extrusions are typically labeled and classified in inches, such as 1/2 inch, 3/4 inch, etc. These extrusions, with their precise dimensions and standardized interfaces, are widely used in fields requiring precise assembly and modular design. The high flexibility of fractional series extrusions makes them ideal for industrial automation, robotics manufacturing, and experimental equipment.

Metric Series

Metric series extrusions are labeled and classified in millimeters, such as 20mm, 40mm, etc. This series is more commonly used internationally, especially in Europe and Asia. Metric series extrusions also offer high modularity and customizability, meeting the needs of various complex structures and systems. They are widely used in automated production lines, material handling systems, and display structures.

8020 aluminum is a type of aluminum alloy, but currently, there is no specific information indicating that it is a standard grade or a widely recognized type of aluminum extrusion. Aluminum alloys are generally classified based on their alloying elements and performance characteristics. For example, the 2xxx series aluminum alloys mainly contain copper, the 6xxx series contain magnesium and silicon, and the 7xxx series contain zinc.

Aluminum extrusion types and series are usually based on alloy composition, performance characteristics, and application fields. Common aluminum extrusion series include:

1xxx Series: Represents pure aluminum or alloys with more than 99.00% aluminum.

2xxx Series: Mainly contains copper, offering high strength, such as 2011, 2014, 2024.

6xxx Series: Mainly contains magnesium and silicon, offering good machinability and weldability, such as 6061, 6063.

7xxx Series: Mainly contains zinc, providing the highest strength, such as 7075.

Aluminum extrusions are widely used in construction, transportation, electronics, machinery, and other fields. Different series of aluminum extrusions are applied in different scenarios based on their characteristics. For example, 6061 and 6063 aluminum extrusions are often used in construction, furniture, and mechanical parts due to their good machinability and weldability.

High Strength

Due to the high proportion of copper, 8020 aluminum has a very high tensile strength.

Good Weldability

The 2xxx series aluminum alloys generally have good welding performance.

Machinability

Aluminum alloys are relatively soft and easy to process into various shapes.

Corrosion Resistance

Aluminum alloys have good corrosion resistance, especially after specific surface treatments.

Lightweight

Compared to other metals, aluminum alloys have a lower density and are lighter in weight.

Stainless Steel

Stainless steel is known for its excellent corrosion resistance and aesthetic appeal. However, 8020 aluminum offers a lighter weight and lower cost, making it a more economical choice for applications not requiring extreme corrosion resistance. Additionally, the ease of processing 8020 aluminum makes it advantageous in complex structures and customized designs.

Steel and Iron

Steel and iron are known for their high strength and load-bearing capacity, but they are heavier and more expensive. 8020 aluminum provides sufficient strength while significantly reducing weight and lowering transportation and installation costs. This makes 8020 aluminum more competitive in fields requiring lightweight design, such as aerospace and automotive manufacturing.

Copper, Brass, Titanium, Magnesium, and Nickel

These metals excel in specific applications but often come with higher costs or greater processing difficulties. 8020 aluminum, with its moderate cost, excellent performance, and ease of processing, becomes a cost-effective choice in various fields. Its advantages are particularly evident in modular design, quick assembly, and cost control scenarios.

When selecting the appropriate machining process for 8020 aluminum CNC parts, factors such as the material's physical properties, machining precision requirements, and production efficiency need to be considered. Common machining processes include CNC milling, CNC turning, laser cutting, bending, and welding.

CNC Milling

Suitable for machining complex shapes and profiles, achieving high precision and high surface quality.

CNC Turning

Suitable for machining shaft parts and rotating parts, achieving precise size control and surface finish.

Laser Cutting

Suitable for rapid cutting and drilling operations, achieving non-contact processing and reducing material waste.

Bending

Suitable for bending and forming operations, achieving precise bending angles and shapes through accurate mold design and control parameters.

Welding

Used when multiple parts need to be joined, such as TIG welding, MIG welding, achieving high strength and sealed joints.

8020 aluminum, as a high-performance aluminum alloy material, has broad application prospects in the field of CNC machining parts manufacturing. Its excellent performance, ease of processing, and modular design make it an ideal choice in various fields. By selecting the appropriate machining process and material specifications, the advantages of 8020 aluminum can be fully utilized to meet various complex and customized needs. In the future, with technological advancements and industrial development, the application fields of 8020 aluminum will be more extensive, bringing innovation and convenience to more industries.

Why is it called 80/20 Aluminum?

The name "80/20" originates from its design philosophy and proportional relationship. In some cases, it might refer to the profile's sectional size ratio (such as 80mm wide and 20mm high), but more broadly, it represents concepts like "80% performance at 20% cost" or "80% efficiency with 20% effort," emphasizing a good balance between performance and economy.

What is the best grade of aluminum for extrusion?

The best grade of aluminum for extrusion depends on specific application requirements. While 8020 aluminum is a common extrusion aluminum alloy, there are many other grades to choose from, such as 6061 and 6063. The best grade is chosen by considering factors like material strength, corrosion resistance, machinability, and cost.

What is the difference between 10 Series and 15 Series 8020 Aluminum?

"10 Series" and "15 Series" might refer to different series or specifications of 8020 aluminum profiles. There isn't a standard differentiation of "10 Series" and "15 Series" for 8020 aluminum profiles. This terminology might be specific to a manufacturer or brand's product classification. Generally, the differences would be in profile dimensions, wall thickness, material composition, mechanical properties, or surface treatment.

What is the yield strength of 80/20 Aluminum?

The yield strength of 80/20 (or 8020) aluminum is not a fixed value as it may vary depending on the specific alloy composition, heat treatment state, and manufacturer. Generally, 8020 aluminum, as a structural aluminum alloy, has high yield strength, but specific values need to be referenced from relevant material datasheets or the supplier.

Does extruded aluminum rust?

Extruded aluminum (including 8020 aluminum) does not rust because aluminum is a highly reactive metal that forms a dense oxide layer in the natural environment. This oxide layer effectively protects the aluminum substrate from further oxidation or corrosion. However, if the surface of the aluminum is scratched, abraded, or exposed to extreme environments (such as strong acids or bases), the protective layer may be damaged, leading to corrosion. Therefore, it is important to protect the aluminum surface in applications and choose appropriate surface treatments to enhance its corrosion resistance.

What is the difference between aluminum and extruded aluminum?

Aluminum is a metallic element characterized by its light weight, good conductivity, good thermal conductivity, and corrosion resistance, and is widely used in various fields. Extruded aluminum refers to aluminum that has been processed and formed through the extrusion process, including various shapes of profiles, tubes, rods, etc. The extrusion process can give aluminum specific shapes and dimensions while enhancing its strength and hardness. Therefore, extruded aluminum is a processed form of aluminum with higher machining precision and better mechanical properties. Unprocessed aluminum (such as aluminum ingots, aluminum plates) requires further processing to meet specific application requirements.

In conclusion, 8020 aluminum, as a high-performance extrusion aluminum alloy material, has broad application prospects in the field of CNC machining parts manufacturing. By understanding its characteristics, selecting the appropriate machining processes and material specifications, its advantages can be fully utilized to meet various complex and customized needs. Additionally, having a clear understanding and knowledge of common questions about 8020 aluminum is essential for better application and maintenance of this high-quality material.