15 years one-stop China custom CNC machining parts factory

642 |

Published by VMT at Jan 26 2025 | Reading Time:About 2 minutes

642 |

Published by VMT at Jan 26 2025 | Reading Time:About 2 minutes

Have you ever wondered, "Does titanium rust?" Many people are curious about titanium’s durability and whether it can corrode like other metals. Titanium is renowned for its strength and resistance to harsh environmental factors, but understanding whether it rusts or not is essential, especially when considering its use in demanding applications like aerospace, medical implants, and marine environments. In this article, we’ll dive into the science behind titanium's corrosion resistance, its properties, and its applications. By the end, you’ll have a clear understanding of titanium’s rust resistance and why it remains one of the most versatile and reliable materials in modern industries.

Titanium is a lightweight, strong, and corrosion-resistant metal widely used in various high-performance industries. This element, represented by the symbol Ti on the periodic table, is known for its high strength-to-weight ratio, making it an excellent choice for applications requiring robust materials without compromising on weight. Titanium is also biologically inert, meaning it doesn't react with most substances, which is why it’s a popular choice for medical devices and surgical implants. Its unique properties make it highly suitable for aerospace, automotive, and chemical industries, where durability is key.

Rust refers to the corrosion of metals, typically iron or steel, caused by the reaction with oxygen and moisture. When exposed to air and water, iron atoms react with oxygen to form iron oxide (rust). This process weakens the metal, compromising its integrity. Unlike other metals, titanium does not rust in the same way, due to its unique composition and protective mechanisms, such as the formation of a natural oxide layer on its surface. This oxide layer provides protection, preventing further corrosion from taking place.

Pure titanium is incredibly resistant to corrosion, including rust. Unlike metals like iron, pure titanium doesn’t easily oxidize or rust. The key reason lies in its ability to form a dense, protective oxide layer when exposed to oxygen. This oxide layer is highly durable and effectively prevents further corrosion, making titanium one of the most rust-resistant materials available. Even when titanium is exposed to extreme environments, this natural barrier protects it, ensuring that it doesn’t rust in typical conditions.

Titanium does not rust in the traditional sense. In environments where other metals would corrode quickly, titanium remains largely unaffected. This is because of the oxide layer that forms almost instantly when titanium is exposed to oxygen. Unlike other metals, this layer doesn’t peel or flake off; instead, it remains intact, protecting the underlying metal. So, rather than rusting over time, titanium maintains its appearance and strength, making it ideal for long-term use in harsh environments.

While rust refers to the corrosion of iron and steel, oxidation of titanium is a completely different process. Titanium does oxidize, but the result is not rust. When exposed to air, titanium forms a thin oxide layer, which acts as a protective barrier, preventing further oxidation or corrosion. This layer is both tough and self-healing. If damaged, it naturally repairs itself by reacting with oxygen, making titanium incredibly resistant to corrosion over extended periods.

Several key factors contribute to titanium's remarkable ability to resist rust and corrosion. These include the formation of a tough oxide layer, its self-healing properties, and its inherent chemical inertness. In the following sections, we’ll explore these factors in more detail to show how they work together to keep titanium rust-free.

Tough Oxide Layer Formation

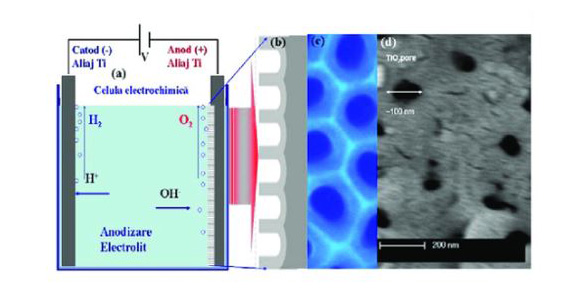

One of the primary reasons why titanium doesn’t rust is its ability to form a dense and stable oxide layer when exposed to oxygen. This layer, composed of titanium dioxide (TiO₂), is highly resistant to corrosion, making titanium a top choice for applications that require long-lasting durability in aggressive environments. The oxide layer serves as a natural barrier, preventing oxygen and moisture from reaching the surface of the metal, thus protecting it from rusting.

Self-Healing Properties of Oxide Layer

One of titanium’s standout features is the self-healing nature of its oxide layer. If the oxide layer is scratched or damaged, titanium reacts with oxygen to regenerate the layer almost immediately. This unique self-repair process ensures that titanium remains rust-free even under harsh environmental conditions, unlike other metals that may start rusting or corroding once their protective layers are damaged.

Chemical Inertness of Titanium

Titanium is chemically inert, meaning it doesn’t react easily with most substances, including water, salts, and acids. This characteristic makes it highly resistant to corrosion and rust in various environments. Whether it’s exposed to saltwater in the marine industry or chemical reagents in industrial settings, titanium will not rust or degrade as many other metals would.

High Strength-to-Weight Ratio

Titanium’s high strength-to-weight ratio is another reason it’s widely used in demanding industries. Despite its lightweight nature, titanium is stronger than steel and many other metals. Its combination of strength, low density, and corrosion resistance make it ideal for aerospace, marine, and medical applications, where durability and long-term performance are crucial.

Titanium's corrosion resistance is one of its most valued properties. Whether used in aerospace, marine, or medical applications, titanium's ability to withstand harsh environments without corroding or rusting ensures its reliability and longevity. Let’s take a deeper look at how titanium resists corrosion in different conditions.

Passivation

Titanium undergoes a process called passivation, which enhances its corrosion resistance. During passivation, the titanium surface is treated to promote the formation of the protective oxide layer, making it even more resistant to oxidation and corrosion. This treatment is often used in medical and aerospace applications to ensure the metal’s reliability in challenging environments.

Chemical Inertness

Titanium’s chemical inertness contributes to its excellent resistance to corrosion. The metal does not react with common environmental agents, including oxygen, water, salt, and chlorides. This makes titanium a preferred material for industries such as chemical processing, marine engineering, and medical devices, where exposure to harsh conditions is frequent.

Biocompatibility

Another benefit of titanium’s corrosion resistance is its biocompatibility. It doesn’t corrode or release harmful substances when in contact with bodily fluids, making it ideal for medical implants such as surgical screws, hip replacements, and dental implants. Titanium’s ability to resist corrosion also ensures the longevity and safety of implants inside the human body.

Low Reactivity with Water

Titanium’s resistance to rust is enhanced by its low reactivity with water. Even in environments with high humidity or exposure to seawater, titanium maintains its structural integrity. The metal forms a protective oxide layer in contact with water, which helps prevent rust formation and keeps the material stable over time.

Stability at High Temperatures

Titanium can also withstand high temperatures without rusting or degrading. This makes it particularly valuable in aerospace and chemical processing applications, where metals are often subjected to extreme heat. The ability to maintain strength and resist corrosion at elevated temperatures further establishes titanium as an excellent material choice in demanding environments.

Titanium’s corrosion resistance far outperforms that of many common metals. For instance, stainless steel and aluminum, though resistant to corrosion, can still corrode under extreme conditions or over time. Titanium, however, maintains its integrity and strength in environments where these metals would degrade, particularly in marine or highly acidic environments.

Several factors influence how well titanium resists rust. These include the environmental conditions, surface treatments, and the alloy composition of titanium. Let’s explore how each of these factors can impact the metal’s rust resistance.

Environmental Conditions

Environmental factors such as humidity, temperature, saltwater, and chemical exposure play a significant role in how titanium behaves over time. Titanium performs exceptionally well in aggressive environments compared to other metals, making it suitable for aerospace, marine, and medical applications.

Surface treatments such as anodizing and passivation can enhance titanium’s natural corrosion resistance. These treatments create an additional layer of protection, further minimizing the risk of rust or corrosion in harsh conditions.

Alloy Composition

The composition of titanium alloys can also affect its resistance to rust. For instance, Grade 5 titanium, commonly used in aerospace and medical applications, contains additional elements like aluminum and vanadium, which enhance its overall strength and corrosion resistance.

Titanium’s remarkable rust-resistant properties make it ideal for a wide range of industries, particularly those where durability and reliability are critical. Let's look at some of the key sectors where titanium is a preferred material due to its corrosion resistance.

Aerospace Industry

Titanium’s high strength-to-weight ratio and corrosion resistance make it a staple in the aerospace industry. Components such as engine parts, airframe structures, and landing gear benefit from titanium’s ability to withstand extreme temperatures and environmental conditions without rusting or degrading.

Marine Industry

In the marine industry, titanium's rust resistance is highly valued for underwater applications. Ship components, submarine parts, and offshore structures are frequently exposed to seawater, which contains high levels of chloride. Titanium, however, is resistant to the corrosive effects of saltwater, which makes it ideal for use in harsh marine environments. Whether it’s for boat hulls or underwater equipment, titanium helps ensure the longevity and reliability of critical infrastructure.

Medical Devices and Implants

Titanium’s biocompatibility and corrosion resistance make it the material of choice for medical implants. It is commonly used in hip replacements, knee implants, dental implants, and surgical tools. Titanium’s ability to resist corrosion in the human body ensures that it remains safe and effective over extended periods. Moreover, it does not release harmful substances into the body, making it one of the safest metals for medical use.

Chemical Processing Industry

Titanium’s chemical inertness and high corrosion resistance make it a valuable material in the chemical processing industry. It is often used in equipment that comes into contact with aggressive chemicals, such as reactors, heat exchangers, and pipelines. Titanium's ability to withstand harsh chemicals without rusting makes it ideal for industries dealing with aggressive substances, ensuring long-lasting performance and minimal maintenance.

While titanium is naturally resistant to rust, certain processes can be used to enhance its durability and corrosion resistance even further. By applying specific surface treatments and coatings, you can ensure that titanium parts maintain their integrity even in the most demanding environments.

Anodizing

Anodizing is a surface treatment process that involves applying an oxide layer to titanium to increase its corrosion resistance. This process thickens the natural oxide layer, making it even more protective. Anodized titanium also has a unique appearance, with a range of colors that result from the formation of different oxide thicknesses. This treatment is widely used in aerospace, medical, and consumer products to enhance the durability and aesthetics of titanium components.

PVD Coatings

Physical Vapor Deposition (PVD) is another effective coating technique for titanium. This process involves vaporizing titanium and depositing it as a thin film onto a substrate, which can further enhance its corrosion resistance. PVD coatings can also improve the hardness and wear resistance of titanium, making it even more suitable for high-stress applications in industries such as aerospace and medical devices.

Passivation

Passivation is the process of treating titanium with a special solution, typically nitric acid, to remove impurities from the surface. This treatment helps to further promote the formation of the oxide layer, ensuring that titanium remains corrosion-resistant even in harsh environments. Passivated titanium surfaces are more resilient against corrosion, making this process common in industries that require the utmost reliability, such as in the production of surgical implants and chemical reactors.

Titanium's natural rust-resistant properties set it apart from many other metals. Thanks to its oxidation resistance, self-healing oxide layer, and chemical inertness, titanium remains a superior choice in industries where corrosion is a major concern. Whether used in aerospace, medical implants, or marine environments, titanium offers unparalleled durability and long-lasting performance, making it a go-to material for the most demanding applications.

VMT offers high-quality titanium CNC machining services to create custom titanium parts for a variety of applications. Whether you need titanium for aerospace, medical implants, or industrial machinery, VMT’s precision CNC machining capabilities ensure that your parts are manufactured to the highest standards of accuracy and performance. With years of experience in titanium CNC machining, VMT is your trusted partner for all your titanium machining needs.

If you're still wondering about titanium’s properties, here are answers to some of the most common questions about whether titanium can rust or not, along with some other frequently asked questions about this incredible metal.

Does Titanium Stain?

Titanium is highly resistant to staining. Unlike stainless steel, which can develop surface discolorations over time, titanium maintains its appearance due to its oxide layer. However, under extreme conditions or exposure to harsh chemicals, titanium may show signs of wear or discoloration, but these are generally not stains in the traditional sense and can often be cleaned or treated.

Does Titanium Rust in Water?

Titanium does not rust in water. In fact, its corrosion resistance is one of its defining features. Titanium forms a protective oxide layer when it comes into contact with water, preventing rust and corrosion. Even in saltwater environments, such as those encountered in marine applications, titanium holds up remarkably well, making it ideal for underwater use.

Will Titanium Rust in Salt Water?

Titanium is resistant to rust even in saltwater. This makes it a favored material for marine applications, such as boat hulls, marine equipment, and submarine parts. The oxide layer on titanium is highly effective at protecting it from the corrosive effects of saltwater, ensuring its durability in challenging maritime environments.

Will Titanium Rust in the Body?

Titanium does not rust in the body. Its biocompatibility and corrosion resistance make it ideal for medical implants, such as dental implants and joint replacements. Titanium remains stable inside the human body, which is why it is widely used in orthopedic and surgical applications.

Will Titanium Rust in Alcohol?

Titanium does not rust in alcohol. Its chemical inertness ensures that it remains stable in most environments, including contact with alcohol, which might corrode or degrade other metals. This makes titanium a preferred material for a range of specialized equipment and applications, including those involving chemical substances.

Will Grade 5 Titanium Rust?

Grade 5 titanium is one of the most widely used titanium alloys, and it shares the same rust-resistant properties as pure titanium. Grade 5 is a mixture of titanium, aluminum, and vanadium, offering increased strength without compromising on corrosion resistance. This alloy will not rust, even in challenging conditions such as high temperatures or saltwater exposure.

Will Titanium Jewelry Rust?

Titanium jewelry is highly resistant to rust. The oxide layer that forms on the surface of titanium prevents it from corroding or rusting. This makes titanium an excellent choice for jewelry, especially for those who want a durable, long-lasting product that will retain its appearance over time.

What Color Will Titanium Rust?

Titanium doesn't rust in the traditional sense, so it won’t develop the reddish-brown color associated with rust. Instead, titanium may show slight discoloration in certain environments, but these are usually the result of surface oxidation, not rust. This oxide layer can give titanium a range of colors, from silver to blue and gold, depending on its thickness.

Does Titanium Rust Easily?

No, titanium does not rust easily. Its oxide layer offers exceptional protection, preventing corrosion from occurring even in harsh environments like saltwater and acidic conditions. Unlike metals such as iron or steel, titanium’s resistance to rust is one of its strongest attributes, ensuring its longevity in various industries.

How Long Will Titanium Take to Rust?

Titanium does not rust under normal conditions. The oxide layer that forms on its surface provides a protective barrier that prevents the metal from corroding. Even in extreme conditions, this layer remains intact, and if it’s damaged, it self-heals by reacting with oxygen, so titanium remains rust-free over time.

Which Metals Will Not Rust?

Some metals that do not rust include titanium, platinum, gold, and aluminum. These metals are highly resistant to corrosion and oxidation, making them ideal for use in harsh environments or specialized applications where rusting would be a concern.

What Metals Are Magnetic But Will Not Rust?

Stainless steel is a magnetic metal that also offers excellent rust resistance. While not as resistant as titanium, certain stainless steel alloys (like 316 stainless steel) perform well in preventing rust and corrosion, even in challenging environments.

Does Titanium Rust More Easily than Stainless Steel?

No, titanium does not rust more easily than stainless steel. In fact, titanium is more resistant to corrosion and rust in most environments. While stainless steel can corrode or rust in certain conditions, titanium remains unaffected due to its protective oxide layer.

Does Titanium Turn Green in Water?

Titanium does not turn green in water. However, if exposed to certain chemicals or chlorine for prolonged periods, titanium may show slight discoloration, which can be cleaned easily. This is not rust, but rather a change in the appearance of the oxide layer.

Is Titanium Magnetic?

No, titanium is not magnetic. This makes it a valuable material in applications where non-magnetic properties are required, such as in MRI machines or aerospace components.