15 years one-stop China custom CNC machining parts factory

989 |

Published by VMT at Jan 25 2025 | Reading Time:About 6 minutes

989 |

Published by VMT at Jan 25 2025 | Reading Time:About 6 minutes

Choosing the right material for medical tools or industrial applications can be a daunting task, especially when it comes to surgical steel and stainless steel. Although both materials are commonly used in similar industries, they have distinct differences that could influence their performance in specific applications. Are you trying to figure out which steel to use for your next project? Understanding the key differences in composition, strength, and corrosion resistance will help you make the right choice. This article explores surgical steel and stainless steel, helping you navigate the similarities and differences so you can make the best decision for your needs.

While surgical steel is a type of stainless steel, it’s engineered for specialized medical applications, offering enhanced corrosion resistance and hypoallergenic properties. Stainless steel, in general, is used for a wide range of applications, from household products to heavy-duty machinery. When you need precision CNC machining for parts like surgical steel CNC machining parts or stainless steel CNC machining parts, understanding the differences is key to getting the best results.

Before we dive into the properties and applications of both materials, let’s first explore the basics of stainless steel and surgical steel to understand what sets them apart. By knowing the types and compositions of these materials, you’ll be better equipped to select the right one for your next project.

Stainless steel is a versatile alloy made primarily of iron, carbon, and chromium, which gives it its corrosion-resistant properties. Due to its resistance to rust, staining, and corrosion, stainless steel is widely used in industries ranging from automotive to food processing. The metal's strength, durability, and aesthetic appeal make it a go-to material in both industrial and consumer applications.

Types of Stainless Steel

There are several types of stainless steel, each with unique properties suited for different applications. These include:

Surgical steel, often referred to as “implant grade stainless steel,” is a specific grade of stainless steel that has been optimized for use in medical and surgical applications. It is designed to be highly resistant to corrosion and is hypoallergenic, making it ideal for implants, prosthetics, and surgical tools that come in contact with the human body. While surgical steel is a subset of stainless steel, its properties make it uniquely suited for medical purposes.

Medical Grade Stainless Steel

Medical-grade stainless steel is engineered to meet specific industry standards for use in surgical implants, medical devices, and equipment. This steel is purified and treated to meet high standards of quality, ensuring biocompatibility and resistance to corrosion, which are essential when the material is in contact with human tissue.

Implant Grade Stainless Steel

Implant-grade stainless steel, such as 316L stainless steel, is a non-corrosive alloy that is used for implants like pacemakers, joint replacements, and dental work. The "L" in 316L refers to its low carbon content, which reduces the risk of sensitization and improves its resistance to corrosion, making it suitable for prolonged contact with bodily fluids.

Medical stainless steels are specially formulated alloys designed to meet the stringent requirements of medical applications, particularly where biocompatibility, corrosion resistance, and strength are critical. These steels are commonly used in the manufacturing of medical implants, surgical instruments, and prosthetics. In this section, we will look at some of the most widely used stainless steel grades in the medical field: 304 stainless steel, 316 and 316L surgical steels, 420 stainless steel, 440 stainless steel, and 630 stainless steel. Each of these materials offers unique properties tailored to specific medical uses.

304 Stainless Steel

304 stainless steel is one of the most commonly used grades in the medical industry. It is a type of austenitic stainless steel that contains high levels of chromium and nickel, which contribute to its excellent corrosion resistance. While it is not typically used for implants, 304 stainless steel is often found in medical instruments, equipment, and accessories. This steel offers good weldability, strength, and resistance to corrosion, making it ideal for tools that require repeated sterilization.

Applications: Surgical tools, hospital equipment, dental instruments, and external medical devices.

316 and 316L Surgical Steels

316 stainless steel is often referred to as “surgical steel” due to its superior corrosion resistance, especially in chloride-rich environments such as bodily fluids. 316L is a low-carbon version of 316 stainless steel, designed to improve its resistance to sensitization, a process that could compromise the steel’s corrosion resistance during welding. These alloys are especially favored in medical applications that require extended contact with body fluids and tissues.

Applications: Bone screws, surgical instruments, pacemaker components, orthopedic implants, and joint replacements.

420 Stainless Steel

420 stainless steel is a martensitic steel known for its high hardness and strength. It contains higher carbon content compared to other stainless steels, which allows it to be hardened via heat treatment. However, it has a lower resistance to corrosion compared to austenitic steels like 316. 420 stainless steel is commonly used for medical tools that require a sharp edge, such as scalpels, scissors, and knives. Due to its hardness, it’s excellent for cutting and surgical procedures but requires proper care to prevent corrosion.

Applications: Surgical scalpels, scissors, forceps, and other cutting tools.

440 Stainless Steel

440 stainless steel is another high-carbon martensitic steel known for its exceptional hardness and edge retention. It is more resistant to wear and abrasion than other stainless steel grades, making it ideal for tools that are used for heavy-duty applications. Like 420 stainless steel, it can be hardened through heat treatment, but it also has a higher resistance to corrosion. However, it is not as corrosion-resistant as 316L.

Applications: High-quality surgical tools, cutting blades, and dental instruments.

630 Stainless Steel

630 stainless steel is a precipitation-hardened steel known for its high strength and corrosion resistance. It is often used in medical applications where high strength is required, such as in the production of implants and surgical devices. The alloy contains significant amounts of chromium and nickel, making it resistant to corrosion in harsh environments. 630 stainless steel is often used in medical devices that require exceptional strength, particularly in joint replacements and orthodontic components.

Applications: Bone fixation devices, dental implants, and orthodontic devices.

Conclusion

These common medical stainless steels — 304, 316/316L, 420, 440, and 630 — offer unique advantages depending on the application. Whether for surgical tools, implants, or medical devices, the choice of steel plays a crucial role in ensuring functionality, safety, and longevity. For critical medical applications, stainless steels like 316L and 630 are often preferred due to their superior corrosion resistance and strength, making them ideal for prolonged contact with the human body.

When choosing between surgical steel and stainless steel for a specific application, it's important to understand their unique properties. While both materials share a core composition of iron, chromium, and other elements, they differ significantly in terms of performance, applications, and benefits. Surgical steel is typically a specific grade of stainless steel, designed for medical use, while stainless steel encompasses a wide range of alloys that are used in diverse industries. In this section, we will dive into the chemical composition, physical properties, and mechanical properties of both materials to give you a comprehensive understanding of their differences.

Surgical Steel vs. Stainless Steel: Chemical Composition

The chemical composition of surgical steel and stainless steel is one of the key factors that differentiate these two materials. Surgical steel is a type of stainless steel, but with stricter standards for biocompatibility and corrosion resistance.

| Designation |

Chemical Composition (Major elements only) % content is a maximum unless a range is indicated |

||||||||||

| SAE |

EN |

C, ≤ |

Mn, ≤ |

P, ≤ |

S, ≤ |

Si, ≤ |

Cr |

Ni |

Mo |

N, ≤ |

Other Elements ≤, UOS |

| 304 |

1.4301 |

0.08 |

2.00 |

0.045 |

0.03 |

1.00 |

18.0-20.0 |

8.0-11.0 |

- | - | - |

| 316 |

1.4401 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

10.0-14.0 |

2.00-3.00 |

- | - |

| 316L |

1.4404 |

0.03 |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

10.0-14.0 |

2.00-3.00 |

- | - |

| 420 |

1.4021 |

0.15, ≥ |

1.00 |

0.04 |

0.03 |

1.00 |

12.0-14.0 |

- | - | - | - |

| 440B |

1.4112 |

0.75-0.95 |

1.00 |

0.04 |

0.03 |

1.00 |

16.0-18.0 |

- | ≤0.75 |

- | - |

| 440C |

1.4125 |

0.95-1.20 |

1.00 |

0.04 |

0.03 |

1.00 |

16.0-18.0 |

- | ≤0.75 |

- | - |

| 630 (17-4) |

1.4542 |

0.07 |

1 | 0.04 |

0.03 |

1 | 15.5-17.5 |

3.0-5.0 |

- | - |

3.0-5.0 Cu; 0.15-0.45 Nb |

Surgical Steel vs. Stainless Steel: Physical Properties

Both surgical steel and stainless steel are known for their durability, resistance to corrosion, and overall strength. However, there are some notable differences in their physical properties:

Surgical Steel vs. Stainless Steel: Mechanical Properties

The mechanical properties of surgical steel and stainless steel play a critical role in their respective applications, particularly in terms of strength, flexibility, and durability.

Properties of Surgical Steel

Surgical steel is a highly specialized material used in medical applications, and its properties are designed to meet the unique challenges posed by the human body. This section covers the key properties that make surgical steel suitable for use in surgical instruments and medical implants.

Properties of Stainless Steel

Stainless steel is a versatile and widely used material in various industries due to its durability and resistance to corrosion. It is often used for a wide range of applications, from construction to food processing. Here are some of the key properties that make stainless steel a popular choice in many sectors:

The key differences between surgical steel and stainless steel stem from their specific formulations, intended uses, and performance characteristics:

Ultimately, while surgical steel can be considered a type of stainless steel, the two materials are designed for distinct purposes, with surgical steel offering enhanced properties tailored to medical applications.

Stainless steel has become one of the most commonly used materials in the medical industry due to its excellent properties, such as corrosion resistance, strength, and biocompatibility. It is used in a wide range of applications, from surgical tools to implants, offering a versatile solution to medical professionals. In this section, we’ll explore the various medical applications of stainless steel, demonstrating its critical role in healthcare.

Orthopedic Implants

Stainless steel plays a crucial role in orthopedic surgery, where implants such as bone plates, screws, and nails are used to repair fractures and stabilize bones. 316L stainless steel is particularly favored due to its excellent corrosion resistance and ability to withstand the stresses and strains placed on the bones during the healing process. The strength, flexibility, and durability of stainless steel make it an ideal choice for implants that need to last a lifetime inside the human body.

Dental Implants

Stainless steel is also used extensively in dental implants and dental instruments. Dental crowns, bridges, and dental screws are often made from stainless steel alloys, which offer both strength and resistance to corrosion from saliva and other oral fluids. 316L stainless steel is often used in dental applications due to its hypoallergenic properties and ability to maintain its integrity within the acidic environment of the mouth.

Surgical and Dental Instruments

From scalpels to forceps, surgical instruments rely heavily on stainless steel for their durability, strength, and resistance to corrosion. Instruments like scissors, scalpels, and needles are typically made from high-grade stainless steel to ensure they can withstand repeated sterilization and the harsh conditions of surgeries. In dental practices, tools like scalers, probes, and pluggers are also fabricated from stainless steel for similar reasons.

Pharmaceutical Equipment: Sample and Material Handling

Stainless steel is extensively used in the pharmaceutical industry for material handling and sample processing. 316 stainless steel is used in pharmaceutical manufacturing due to its resistance to corrosion from various chemicals and its ability to maintain purity standards. Equipment such as mixers, pumps, and reactors often rely on stainless steel to ensure they do not contaminate sensitive pharmaceutical products.

Stainless Steel Tubing

Stainless steel tubing is vital in medical applications where flexible yet strong materials are required, such as in IV lines, catheters, and endoscopes. Tubing made from stainless steel is resistant to corrosion, making it safe for long-term use in the human body or in medical equipment that comes in contact with bodily fluids.

Bone Fixation

In orthopedic surgery, stainless steel is used in bone fixation devices such as plates, screws, and wires. These devices are crucial in holding broken bones together while they heal. Stainless steel is chosen for its strength, ability to withstand high stresses, and its ease of sterilization. 316L stainless steel is particularly ideal for its strength and corrosion resistance.

Wires

Stainless steel wires are commonly used in medical procedures for suturing, as well as for internal fixation in surgeries like spine or orthopedic surgeries. Stainless steel offers the necessary strength and durability for wires to hold tissue or bone together during the healing process. The material’s resistance to corrosion is particularly important in ensuring long-term functionality without degradation.

Curettes

In surgery, curettes are instruments used for scraping tissue or debris from body cavities. Stainless steel is the preferred material for curettes due to its strength, resistance to wear, and the ability to maintain a sharp edge even after repeated use. Surgical stainless steel ensures that these tools remain durable, sterile, and capable of performing delicate procedures.

Plates and Screws

In orthopedic and trauma surgeries, plates and screws made from stainless steel are used to stabilize broken bones or joints. 316L stainless steel is commonly used in this application because of its exceptional resistance to corrosion, high strength, and compatibility with the human body. These components are critical in providing long-lasting solutions for bone fractures, especially in demanding environments.

Prosthetics

Prosthetic limbs and implants are often made from stainless steel alloys. Stainless steel prosthetics offer the necessary strength and flexibility for functionality while being resistant to corrosion and easy to clean. These prosthetic devices include everything from artificial joints and limbs to internal fixation devices used for reconstructive surgeries.

Syringes and Needles

Syringes and needles made from stainless steel are crucial for injections and blood sampling in healthcare. Stainless steel’s resistance to corrosion and its sharpness are essential for ensuring accurate procedures and preventing contamination. Stainless steel is also used to make hypodermic needles that can withstand sterilization processes without degradation.

Catheters

Catheters made from stainless steel are used in a variety of medical treatments, including in the treatment of cardiovascular diseases, dialysis, and for draining fluids from the body. Stainless steel catheters are highly resistant to corrosion and can withstand frequent sterilization. They are also strong enough to withstand internal pressure, which is crucial for their proper function.

Sensor Probes

Sensor probes used in medical diagnostics, such as those found in electrocardiograms (EKGs), blood pressure monitors, and other diagnostic equipment, are often made of stainless steel. The strength, durability, and biocompatibility of stainless steel ensure that the probes can function properly in the human body while resisting the corrosion that can occur from long-term exposure to moisture.

Hospital Furniture

Stainless steel is used in various pieces of hospital furniture such as beds, chairs, and trolleys due to its durability, ease of cleaning, and resistance to corrosion. Stainless steel hospital furniture can withstand the rigors of daily use in a hospital environment and maintain its appearance even after repeated cleaning and sterilization procedures.

Surgical Tools

Finally, surgical tools such as scalpels, scissors, forceps, and scalpels are commonly made from stainless steel. These tools need to be durable, resistant to corrosion, and capable of being sterilized repeatedly without degradation. Stainless steel’s ability to hold a sharp edge and maintain strength over time makes it ideal for such critical medical instruments.

Conclusion

From orthopedic implants to surgical tools, stainless steel is a vital material in the medical industry. Its versatility, combined with its corrosion resistance, strength, and biocompatibility, ensures its continued use in a wide range of applications. As medical technology evolves, stainless steel will undoubtedly remain a key material, offering both functionality and safety in healthcare settings.

| Grade |

304 |

316 |

316L |

420 | 440B | 440C | 630 (17- 4) |

| Orthopedic implant devices |

X |

X |

|||||

| Dental implant devices |

X |

||||||

| Surgical and dental instruments |

X |

X |

X | X | X | X | |

| Pharmaceutical equipment: sample & material handling |

X | ||||||

| Stainless steel tubing |

X | ||||||

| Bone fixation |

X | ||||||

| Containers for hazardous materials |

X | ||||||

| Wires |

X | ||||||

| Curettes |

X | ||||||

| Plates and screws |

X | ||||||

| Prostheses |

X | ||||||

| Syringes and needles |

X | ||||||

| Catheters |

X | ||||||

| Sensor probes |

X | ||||||

| Hospital furniture |

X | X |

Both surgical steel and stainless steel have broad applications across industries due to their superior strength, corrosion resistance, and versatility. While surgical steel is commonly used in medical applications, stainless steel is employed in many industrial sectors. Let’s dive into how each metal is applied in different industries and parts.

Applications of Surgical Steel

Surgical steel, also referred to as medical-grade stainless steel, is primarily used in medical applications where biocompatibility, corrosion resistance, and strength are crucial. Its primary use is in the medical field, especially for implants, surgical instruments, and tools. 316L stainless steel is the most common type of surgical steel, offering resistance to corrosion and strength suitable for the human body’s internal environment. Some of the key applications of surgical steel include:

Applications of Stainless Steel

Stainless steel is widely used across industries due to its robust properties, such as corrosion resistance, strength, and formability. Unlike surgical steel, stainless steel is used for a broader range of applications, both in the medical and industrial sectors. Some of the key uses of stainless steel include:

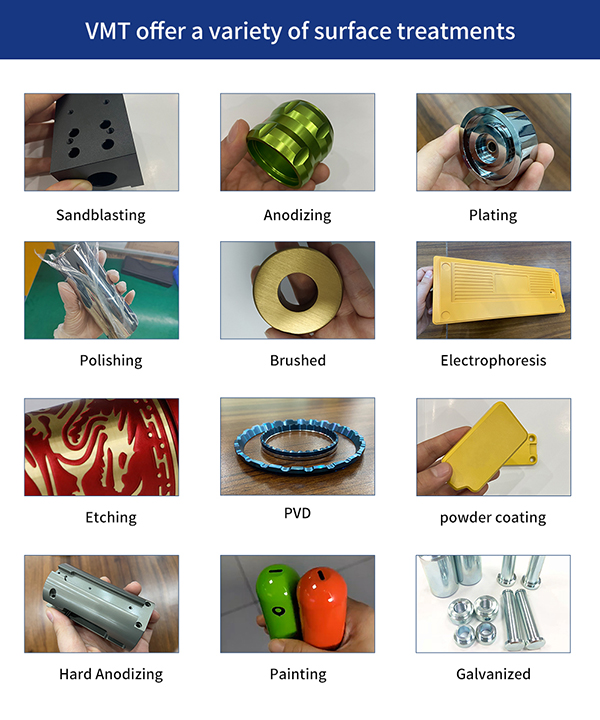

Surface treatment plays a critical role in enhancing the properties of surgical steel and stainless steel. These treatments improve the metals’ durability, corrosion resistance, and aesthetic appeal. Let’s explore the surface treatments that can be applied to each metal.

Introduction to Surface Treatments

Both surgical steel and stainless steel require surface treatments to ensure they perform optimally in their respective applications. Whether for medical or industrial use, these treatments help the metals maintain strength, resistance to wear, and aesthetic quality. Common surface treatments include passivation, electropolishing, coating, and grinding.

What Surface Treatments Can Be Applied to Surgical Steel Parts?

What Surface Treatments Can Be Applied to Stainless Steel Parts?

Both surgical steel and stainless steel offer numerous benefits, but they also have their limitations. Understanding the advantages and disadvantages of each material can help in making informed decisions about which one to use for specific applications.

Advantages of Surgical Steel

Advantages of Stainless Steel

Disadvantages of Surgical Steel

Disadvantages of Stainless Steel

Conclusion

Both surgical steel and stainless steel offer unique benefits for specific applications. Surgical steel excels in the medical field, offering unmatched biocompatibility and strength for implants and surgical instruments. On the other hand, stainless steel has widespread use across industries like construction, food processing, and appliance manufacturing due to its versatility and corrosion resistance. By understanding the distinct properties and applications of each material, you can make the best choice for your needs, whether in a medical or industrial setting.

When deciding between surgical steel and stainless steel for your project, several factors must be taken into consideration. The key differences between these two metals lie in their cost, applications, machinability, machining waste, and aesthetic requirements. Understanding these differences can help you make an informed decision, whether you are working in the medical field, industrial settings, or consumer applications.

Cost

Surgical steel, due to its specialized properties, is typically more expensive than standard stainless steel. The high cost of 316L surgical steel, for example, is a result of its specific formulation that ensures biocompatibility, corrosion resistance, and strength for use in medical applications. For medical implants, surgical instruments, or prosthetics, surgical steel is often the preferred choice despite its higher price.

Stainless steel, on the other hand, is more affordable and widely used across many industries, such as construction, automotive, aerospace, and consumer goods. Its cost-effectiveness makes it ideal for large-scale manufacturing of parts and tools that do not need to meet stringent biocompatibility standards.

Application

Surgical steel is designed specifically for medical and surgical applications. Its biocompatibility ensures it is safe for use in the human body, making it ideal for implants, surgical tools, and piercings. The 316L grade of surgical steel, in particular, is commonly used for applications that require non-reactivity and long-term performance within the body, such as joint replacements, orthopedic implants, and dental implants.

In contrast, stainless steel is more versatile and can be used across a wider range of industries. It is perfect for applications requiring corrosion resistance and strength but where biocompatibility is not critical. Stainless steel is often used in food processing, construction, automotive, aerospace, and appliances. Parts like surgical instruments in less invasive procedures or medical equipment in non-critical environments may also use stainless steel for its affordability and practicality.

Machinability

When it comes to machinability, stainless steel generally fares better than surgical steel. Stainless steel alloys, like 304 and 316, are easier to machine, form, and weld due to their lower hardness and more malleable nature. This makes them ideal for mass production in various industrial applications.

Surgical steel, particularly in the form of 316L, is harder and more challenging to machine. The high tensile strength and corrosion-resistant nature of surgical steel require specialized equipment and more careful handling to avoid wear on cutting tools. This can increase the manufacturing time and overall cost of parts made from surgical steel, especially when intricate or precise machining is required.

Machining Waste

The machining waste generated by stainless steel tends to be lower compared to surgical steel. This is because stainless steel is easier to cut, shape, and form, leading to less waste during the manufacturing process. The more efficient machinability of stainless steel allows for a cleaner and more cost-effective production, especially when working with custom CNC machining services.

In comparison, surgical steel, due to its increased hardness, tends to produce more waste during machining. Special care is required to minimize scrap material, making the machining process for surgical steel more costly and time-consuming. This increased waste is a consideration when deciding which material to choose for cost-sensitive applications.

Aesthetic Requirements

Stainless steel is often preferred for applications that require an aesthetic appeal. Its shiny, smooth surface and resistance to staining make it ideal for products like kitchenware, appliances, and architectural features. Stainless steel’s ability to retain its glossy finish even after prolonged use is a significant advantage in industries where appearance matters.

On the other hand, surgical steel, while highly polished and aesthetically pleasing in medical devices, is primarily chosen for its functional properties rather than appearance. It is more about durability and corrosion resistance than aesthetics. For example, surgical steel used in medical implants or surgical tools is often polished for sterilization and ease of cleaning but is not designed to be aesthetically pleasing in the same way that stainless steel is in consumer goods.

When selecting steel for surgical applications, it's essential to consider the following factors:

Choosing the right steel quality involves balancing these factors with the specific needs of the surgical procedure and cost-effectiveness. For high-stakes, long-term implants, 316L surgical steel is often the preferred choice, whereas stainless steel may be used for tools and instruments that don't need to be implanted.

Selecting the best steel depends on the specific application:

At VMT, we provide advanced CNC machining services for both surgical steel and stainless steel. Whether you're in need of custom CNC machining for surgical steel implants, medical devices, or stainless steel industrial parts, we have the expertise and capabilities to deliver high-quality results.

Our CNC machining factory uses state-of-the-art technology to create precise, high-performance components tailored to your specific requirements. From CNC prototype machining to large-scale production runs, we ensure that each part is manufactured to the highest standards of quality and performance.

Choosing between surgical steel and stainless steel depends on your specific needs, including cost, application, machinability, and aesthetic requirements. Surgical steel excels in medical applications due to its biocompatibility, strength, and corrosion resistance, making it the best choice for implants and surgical instruments. Stainless steel, on the other hand, offers versatility, affordability, and durability, making it suitable for a broad range of industrial and consumer applications.

When selecting the appropriate material, consider the functional demands of your application and the balance between performance and cost. If you're unsure about which steel to choose, VMT’s CNC machining services can help you identify the best material for your project, ensuring optimal performance and value.

Is surgical steel the same as stainless steel?

No, surgical steel is a specific grade of stainless steel. While all surgical steel is stainless steel, not all stainless steel is surgical steel. Surgical steel, such as 316L, is specially formulated for medical applications due to its high biocompatibility, corrosion resistance, and strength. It is often used in medical implants, surgical instruments, and body jewelry.

Does surgical steel rust?

While surgical steel is highly resistant to rust and corrosion, it is not completely immune to it. 316L surgical steel, for instance, is designed to resist rust, but exposure to harsh chemicals, saltwater, or extreme conditions can still cause corrosion over time, especially if the steel’s protective layer is damaged.

Does surgical steel heal itself?

No, surgical steel does not have the ability to "heal itself." However, it is resistant to rust and corrosion due to its high chromium content, which forms a passive protective layer on the surface. This helps prevent degradation in the presence of moisture and oxygen but does not "self-heal" like some advanced materials might.

Does surgical steel stain?

Surgical steel is designed to be stain-resistant. However, like any metal, it can develop stains or discoloration over time, especially if exposed to harsh chemicals or high humidity. Regular cleaning can help maintain its shiny and smooth appearance.

Is surgical steel magnetic?

Most surgical steels, especially 316L, are non-magnetic due to their austenitic structure. However, some grades of surgical steel, like 420 surgical steel, can exhibit magnetic properties. This is because martensitic stainless steels can become magnetized due to their crystal structure.

Is stainless steel better than surgical steel?

It depends on the application. Surgical steel is specifically designed for medical and biomedical applications where corrosion resistance, biocompatibility, and strength are critical. Stainless steel, on the other hand, is better suited for general industrial uses such as automotive, construction, and appliances, where these properties may not be as critical.

Does surgical steel tarnish?

Surgical steel does not tarnish in the traditional sense due to its high chromium content, which forms a protective oxide layer. However, it can lose its shine or appearance if exposed to harsh conditions, chemicals, or abrasive materials. Proper care and cleaning can prevent tarnishing.

Should I choose titanium or stainless steel?

The choice between titanium and stainless steel depends on your specific needs:

Why do doctors use titanium in orthopedic surgery?

Doctors often use titanium in orthopedic surgeries because of its light weight, biocompatibility, strength, and corrosion resistance. Titanium implants are well-tolerated by the body, allowing for faster healing and reduced risk of rejection compared to other metals.

What is the strongest metal?

While titanium is one of the strongest metals in terms of strength-to-weight ratio, tungsten is often considered the strongest metal overall due to its high tensile strength. However, for surgical applications, titanium and surgical steel are preferred for their biocompatibility and overall strength.

Does surgical steel turn black?

Surgical steel can develop a darkened appearance if it becomes exposed to specific chemicals, environmental conditions, or abrasives. However, it does not naturally "turn black" like some other metals. Cleaning and maintenance can restore its natural shine and prevent discoloration.

Which is better for bone fractures, titanium or stainless steel?

Titanium is generally preferred for bone fractures and implants due to its biocompatibility, light weight, and ability to bond well with bone. It’s also less likely to cause rejection. However, stainless steel is still commonly used for temporary bone fixation in orthopedic surgeries because it is strong, durable, and more affordable.

Is surgical steel waterproof?

Surgical steel is highly resistant to water and corrosion due to its protective oxide layer. However, it is not completely "waterproof." It can withstand prolonged exposure to water, but over time, continuous exposure to water, especially salty or chlorinated water, may lead to wear or corrosion if not properly maintained.

Is surgical steel titanium?

No, surgical steel and titanium are two different metals. Surgical steel is a type of stainless steel known for its biocompatibility and corrosion resistance, primarily used in medical implants and tools. Titanium, on the other hand, is a different material known for its strength-to-weight ratio and biocompatibility in surgical and aerospace applications.

What is surgical steel made of?

Surgical steel is primarily composed of iron, chromium, nickel, and molybdenum, with some variations based on the specific grade. For example, 316L surgical steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which provide its unique properties such as corrosion resistance, strength, and biocompatibility.

These FAQs aim to provide clarity on the key differences and properties of surgical steel and stainless steel. Understanding these distinctions can help you make informed decisions when selecting materials for medical, industrial, or other specific applications.