15 years one-stop China custom CNC machining parts factory

273 |

Published by VMT at Nov 10 2024 | Reading Time:About 4 minutes

273 |

Published by VMT at Nov 10 2024 | Reading Time:About 4 minutes

Are you grappling with selecting the right material for your CNC machining parts, only to be confounded by varying material densities and their impact on your projects? Frustrated by the lack of clear information on how the density of stainless steel affects your custom CNC machining operations? You're not alone. Many in the CNC machining industry struggle with these issues, leading to inefficient processes and subpar products. But what if understanding the density of stainless steel could streamline your operations, improve product quality, and enhance customer satisfaction?

The density of stainless steel typically ranges between 7,750 kg/m³ and 8,050 kg/m³, depending on its grade and composition. This density is crucial in CNC machining as it affects material selection, machining parameters, and overall product performance. Understanding stainless steel's density ensures optimal design and manufacturing in CNC machining services.

Now that we've highlighted the importance of stainless steel's density in CNC machining parts manufacturing, let's delve deeper into what density means, the characteristics of stainless steel, and how various factors influence its density. This comprehensive guide will equip you with the knowledge to make informed decisions in your CNC machining projects.

Introduction

Stainless steel is a cornerstone material in modern manufacturing, renowned for its corrosion resistance, strength, and aesthetic appeal. In CNC machining parts manufacturing, stainless steel is often the material of choice for applications requiring durability and precision. However, understanding its density is essential for optimizing machining processes, ensuring structural integrity, and achieving desired product outcomes in custom CNC machining.

The density of a material influences its weight, strength-to-weight ratio, and how it responds to machining operations. In a CNC machining factory, knowledge of stainless steel's density aids in selecting the appropriate machining parameters, tools, and processes. This guide provides an in-depth exploration of stainless steel's density, factors affecting it, and its implications in CNC machining services.

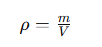

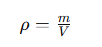

Density is a fundamental physical property defined as the mass per unit volume of a substance. It quantifies how much matter is packed into a given space. Mathematically, density (ρ) is expressed as:

Where:

In the context of CNC machining parts, understanding the density of materials like stainless steel helps engineers and machinists calculate weight, design components that meet structural requirements, and select suitable materials for specific applications.

Units of Measurement of Density

Density is typically measured in kilograms per cubic meter (kg/m³) in the International System of Units (SI). However, other units like grams per cubic centimeter (g/cm³) and pounds per cubic inch (lb/in³) are also commonly used, especially in material specifications for CNC machining services.

For practical purposes in a CNC machining factory, using g/cm³ or kg/m³ is standard, facilitating calculations related to material properties, machining parameters, and product design in custom CNC machining projects.

The density of stainless steel varies depending on its grade and chemical composition but generally falls within the range of 7,750 kg/m³ to 8,050 kg/m³ (or 7.75 g/cm³ to 8.05 g/cm³). This range is due to the different alloying elements used in stainless steel, such as chromium, nickel, molybdenum, and others, which affect both its mechanical properties and density.

In CNC machining parts manufacturing, knowing the exact density of the specific stainless steel grade being used is crucial. It influences the weight calculations of the final product, machining feed rates, cutting speeds, and tool wear. For instance, grades with higher densities may require adjustments in machining parameters to ensure precision and surface finish quality in custom CNC machining.

Understanding the density also aids in material selection for applications where weight is a critical factor, such as in aerospace or automotive components manufactured in a CNC machining factory.

Stainless steel is an alloy known for its exceptional properties that make it ideal for a wide range of applications in CNC machining services. Its unique combination of mechanical strength, corrosion resistance, and aesthetic appeal sets it apart from other materials. Let's explore these characteristics in detail.

Excellent Corrosion Resistance

One of the most significant advantages of stainless steel is its corrosion resistance. The presence of chromium (at least 10.5%) in stainless steel allows the formation of a passive oxide layer on the surface, which prevents further corrosion. This property is invaluable in CNC machining parts exposed to harsh environments, chemicals, or moisture, ensuring longevity and reliability.

Good Strength and Hardness

Stainless steel exhibits excellent mechanical strength and hardness, making it suitable for components that must withstand high stress or wear. In custom CNC machining, this property allows for the production of durable parts that maintain their integrity under demanding conditions.

Easy to Clean and Antibacterial

The smooth surface and resistance to corrosion make stainless steel easy to clean and maintain. Its antibacterial properties are especially beneficial in medical, food processing, and pharmaceutical industries, where hygiene is paramount. CNC machining services often produce stainless steel components for equipment and devices in these sectors.

Excellent High-Temperature Resistance

Stainless steel maintains its mechanical properties at elevated temperatures, making it suitable for applications involving heat exposure. Grades like 310 and 321 are specifically designed for high-temperature environments. In a CNC machining factory, this property is crucial when manufacturing parts for engines, turbines, or heat exchangers.

High Toughness and Plasticity

The toughness and plasticity of stainless steel allow it to absorb energy and deform without fracturing, which is essential in applications subject to impact or vibration. This characteristic enhances the performance and safety of CNC machined parts in automotive, aerospace, and construction industries.

Beautiful Appearance

Stainless steel's aesthetic appeal, with its lustrous finish and ability to maintain its appearance over time, makes it a popular choice for architectural and consumer products. Custom CNC machining can produce intricate and visually appealing components that meet both functional and aesthetic requirements.

Easy to Process and Weld

Despite its strength, stainless steel is relatively easy to machine and weld, especially with the right equipment and expertise. CNC machining services can efficiently process stainless steel into complex shapes and structures, offering versatility in design and application.

Wear Resistance and Fatigue Resistance

Stainless steel's resistance to wear and fatigue ensures that components have a long service life, even under repetitive stress or abrasive conditions. This property is essential in CNC machining parts like bearings, gears, and shafts.

Environmental Protection and Recyclability

Stainless steel is 100% recyclable without loss of quality, contributing to environmental sustainability. In a CNC machining factory, using stainless steel aligns with eco-friendly practices and reduces material waste.

Acid and Alkali Resistance

Stainless steel's resistance to acidic and alkaline environments extends its applicability to chemical processing, marine, and industrial applications. Custom CNC machining can produce parts that perform reliably in these challenging conditions.

Physical Properties

Chemical Properties

Understanding these characteristics helps CNC machining services tailor their processes to produce high-quality stainless steel parts that meet specific application requirements.

Factors Affecting the Density of Stainless Steel

The density of stainless steel is influenced by several factors, primarily related to its composition and microstructure. In CNC machining parts manufacturing, recognizing these factors allows for better material selection and machining strategies.

7 Factors Affecting the Density of Stainless Steel

1. Alloy Composition

The primary factor affecting stainless steel's density is its alloy composition. Different alloying elements have varying atomic masses, which influence the overall density of the alloy. For example:

Nickel: Has a density of 8.90 g/cm³, increasing the density when added.

In custom CNC machining, selecting the appropriate stainless steel grade with the desired density is crucial for meeting weight and performance specifications.

2. Temperature and Pressure

Temperature and pressure can cause thermal expansion or contraction, slightly affecting density. At higher temperatures, stainless steel expands, decreasing density. In a CNC machining factory, accounting for thermal effects ensures dimensional accuracy during machining processes.

3. Porosity and Grain Size

The presence of porosity or variations in grain size can influence density. Porous materials have lower density due to voids within the structure. Controlling manufacturing processes to minimize porosity is essential in CNC machining services to achieve consistent material properties.

4. Tensile Strength

While tensile strength itself doesn't directly affect density, the heat treatments and alloying elements used to enhance strength can alter density. Higher strength grades may have higher densities due to additional alloying elements.

5. Hardness

Similar to tensile strength, hardness is influenced by composition and heat treatment. Changes in these parameters can slightly affect density, which is important in applications where weight and balance are critical.

6. Ductility

Ductility refers to the material's ability to deform under tensile stress. Alloying elements that improve ductility may affect density. In CNC machining parts that require forming or shaping, understanding this relationship is vital.

7. Corrosion Resistance

Adding elements like molybdenum to enhance corrosion resistance can increase density. Selecting the right balance between corrosion resistance and density is essential in custom CNC machining, especially for parts exposed to corrosive environments.

By considering these factors, CNC machining services can optimize material selection and machining parameters to produce high-quality stainless steel components.

Stainless steel is categorized into different grades based on its microstructure: austenitic, ferritic, martensitic, and duplex. Each category has distinct properties and densities, affecting their suitability for various applications in CNC machining parts manufacturing.

Austenitic Stainless Steel

Austenitic stainless steels are the most widely used, known for their excellent corrosion resistance and formability. They typically have densities around 7.90 g/cm³. Grades include 304, 316, 310, and 321.

Ferritic Stainless Steel

Ferritic stainless steels have a body-centered cubic structure and are magnetic. They offer good corrosion resistance and have densities around 7.75 g/cm³. Common grades are 430, 409, and 446.

Martensitic Stainless Steel

Martensitic stainless steels are known for their high strength and hardness but lower corrosion resistance. Their densities are approximately 7.70 g/cm³. Grades include 410, 420, and 440C.

Duplex Stainless Steel

Duplex stainless steels have a mixed microstructure of austenite and ferrite, offering high strength and excellent corrosion resistance. Their densities are about 7.80 g/cm³. Grades include 2205, 2507, and 2304.

| Stainless Steel Grades |

Density (g/cm³) |

| Austenitic Stainless Steel |

7.90 g/cm³ |

| Ferritic Stainless Steel |

7.75 g/cm³ |

| Martensitic Stainless Steel | 7.70 g/cm³ |

| Duplex Stainless Steel |

7.80 g/cm³ |

Density of Austenitic Stainless Steel

304

316

310

321

Density of Ferritic Stainless Steel

430

409

446

Density of Martensitic Stainless Steel

410

420

440C

Density of Duplex Stainless Steel

2205

2507

2304

| Stainless Steel |

Density (g/cm³) |

Characteristics |

Applications |

| 304 |

7.90 g/cm³ |

Excellent corrosion resistance, good formability. |

Kitchen equipment, chemical containers, architectural paneling. |

| 316 |

7.98 g/cm³ |

Enhanced corrosion resistance with molybdenum addition. |

Marine equipment, pharmaceutical equipment, surgical instruments. |

| 310 |

7.95 g/cm³ |

High-temperature resistance. |

Furnace parts, heat exchangers. |

| 321 |

7.92 g/cm³ |

Stabilized with titanium to prevent carbide precipitation. |

Aerospace components, exhaust manifolds. |

| 430 |

7.75 g/cm³ |

Good corrosion resistance, magnetic. |

Automotive trim, dishwasher linings. |

| 409 |

7.74 g/cm³ |

Heat-resistant, used in automotive exhaust systems. |

Mufflers, catalytic converters. |

| 446 |

7.70 g/cm³ |

Excellent resistance to high-temperature corrosion. |

Furnace components, boiler baffles. |

| 410 |

7.75 g/cm³ |

High strength, moderate corrosion resistance. |

Cutlery, valves, pumps. |

| 420 |

7.74 g/cm³ |

Higher carbon content, can be hardened. |

Surgical instruments, needle valves. |

| 440C |

7.78 g/cm³ |

Highest hardness and wear resistance among stainless steels. |

Ball bearings, knives. |

| 2205 |

7.80 g/cm³ |

High strength, excellent corrosion resistance |

Chemical processing, pressure vessels. |

| 2507 |

7.82 g/cm³ |

Super duplex with even higher strength and corrosion resistance |

Offshore platforms, heat exchangers. 2304 |

| 2304 |

7.80 g/cm³ |

Balanced properties of austenitic and ferritic steels |

Storage tanks, structural applications. |

Comparing the density of stainless steel to other metals provides insight into material selection for CNC machining parts, especially when weight is a critical factor.

|

Metal |

Density (g/cm³) |

| Density of Titanium |

4.51 g/cm³ |

| Density of Iron |

7.87 g/cm³ |

| Density of Steel (Carbon Steel) |

7.85 g/cm³ |

| Density of Tool Steel |

7.70 - 8.00 g/cm³ |

| Density of Alloy Steel |

7.80 - 8.00 g/cm³ |

| Density of Aluminum |

2.70 g/cm³ |

| Density of Copper |

8.96 g/cm³ |

| Density of Bronze |

8.80 - 8.90 g/cm³ |

| Density of Nickel |

8.90 g/cm³ |

| Density of Magnesium |

1.74 g/cm³ |

| Density of Zinc |

7.14 g/cm³ |

| Density of Tungsten |

19.25 g/cm³ |

| Density of Gold |

19.32 g/cm³ |

| Density of Platinum |

21.45 g/cm³ |

Stainless steel's density is higher than aluminum and titanium but lower than copper and precious metals. In custom CNC machining, this knowledge aids in balancing weight and performance requirements.

Accurate measurement of stainless steel's density is essential for quality control, material verification, and design calculations in CNC machining services.

Methods for Measuring Density

Archimedes Principle

This method involves submerging the stainless steel sample in a fluid and measuring the displaced volume. It's suitable for irregularly shaped parts produced in a CNC machining factory.

Pycnometer Method

A pycnometer is a device used to measure the volume of liquids or solids. By knowing the mass and volume, density can be calculated precisely.

Gamma Ray Densitometry

This non-destructive testing method uses gamma rays to measure density variations within a material, useful for detecting internal defects in CNC machined parts.

Gas Pycnometer Method

This technique measures the volume of a solid by the amount of gas it displaces, providing high accuracy for porous or powdered materials.

Calculating Density

To calculate density, measure the mass using a precision balance and the volume using appropriate methods. Apply the density formula:

Ensure measurements are accurate and units are consistent to obtain reliable results.

Equipment Required

Accurate density measurement requires specialized equipment:

Guide to Density Calculations

Follow these best practices to ensure accurate density measurements:

The density of stainless steel plays a significant role in its suitability for various industries. Understanding how density affects performance helps CNC machining services tailor solutions to specific needs.

Aerospace

In aerospace applications, weight reduction is critical. While stainless steel is denser than alternatives like aluminum and titanium, its strength and corrosion resistance make it suitable for specific components. CNC machining factories produce precision parts where material properties outweigh density concerns.

Stainless steel's biocompatibility and ease of sterilization make it ideal for medical instruments and implants. Density affects the weight and balance of surgical tools, impacting ergonomics and usability.

In the automotive industry, balancing weight and strength is essential for performance and fuel efficiency. Stainless steel components manufactured through custom CNC machining provide durability in exhaust systems, structural parts, and fasteners.

Stainless steel's density contributes to its robustness in industrial machinery and equipment. Components like valves, pumps, and fittings benefit from its mechanical properties and longevity.

Construction

Architectural applications leverage stainless steel's aesthetic appeal and structural integrity. Density considerations influence design choices for cladding, railings, and support structures.

Manufacturing

In manufacturing processes, stainless steel tools and molds produced by CNC machining services offer wear resistance and dimensional stability, essential for high-precision operations.

Marine Applications

Stainless steel's corrosion resistance in saltwater environments makes it indispensable in marine applications. Density impacts the buoyancy and stability of components like propellers, fittings, and structural elements.

Density is a critical factor in material selection, affecting not only weight but also performance, cost, and environmental impact.

Weight Considerations in Structural Design

In structural applications, material density directly affects the overall weight of the assembly. Engineers must balance the need for strength with the desire to minimize weight, especially in aerospace and automotive industries.

Balancing Force and Weight

Higher density materials may offer greater strength but add to the weight, influencing dynamics and energy consumption. In CNC machining parts, optimizing this balance is key to achieving desired performance.

Environmental and Economic Impacts

Material density affects transportation costs, energy consumption during machining, and recyclability. Selecting the appropriate density contributes to sustainability goals and cost efficiency in CNC machining services.

Understanding the density of stainless steel is fundamental for professionals in CNC machining parts manufacturing. It influences material selection, machining parameters, structural design, and overall product performance. By comprehensively exploring the factors affecting density, the properties of various stainless steel grades, and the methods for measuring and calculating density, this guide equips you with the knowledge to make informed decisions in custom CNC machining projects.

Whether you're producing prototypes in a CNC machining factory or delivering large-scale CNC machining services, considering the density of stainless steel ensures that your products meet the highest standards of quality, efficiency, and customer satisfaction.

What Is the Density of Stainless Steel in kg/m³?

The density of stainless steel typically ranges from 7,750 kg/m³ to 8,050 kg/m³. The exact value depends on the specific grade and composition of the stainless steel alloy used.

What Is the Density of Pure Stainless Steel?

Stainless steel is an alloy and not a pure element. However, the density of standard austenitic stainless steel like 304 is approximately 7,900 kg/m³.

What Is the Density of SS316 Stainless Steel?

The density of SS316 stainless steel is approximately 7,980 kg/m³ (or 7.98 g/cm³). This grade contains molybdenum, which slightly increases its density compared to 304 stainless steel.

What Is the Density of 306 Stainless Steel?

There seems to be a confusion, as 306 stainless steel is not a commonly recognized grade. It's possible that you are referring to 304 or 316 stainless steel. If so, please refer to the densities provided for those grades.

What Are the Components of Stainless Steel?

Stainless steel is primarily composed of iron, chromium (at least 10.5%), and varying amounts of nickel, molybdenum, carbon, and other elements. The specific composition depends on the grade and desired properties.

Which Is Better, 316 Stainless Steel or 304 Stainless Steel?

316 stainless steel offers better corrosion resistance, especially against chlorides and acids, due to its molybdenum content. 304 stainless steel is more cost-effective and provides adequate corrosion resistance for many applications. The choice depends on the specific requirements of your application.

What Is the Density of 300 Stainless Steel?

The 300 series includes various grades. Generally, the density ranges from 7,890 kg/m³ to 7,990 kg/m³. For example, 304 stainless steel has a density of about 7,900 kg/m³.

Which Is Better, 300 Stainless Steel or 304 Stainless Steel?

304 stainless steel is part of the 300 series and is one of the most commonly used grades. The term "300 stainless steel" is broad. For specific applications, you should compare the exact grades (e.g., 304 vs. 316) based on properties like corrosion resistance, strength, and cost.

What Is the Density of 304L Stainless Steel?

The density of 304L stainless steel is approximately 7,900 kg/m³. The "L" denotes low carbon content, which improves weldability without significantly affecting density.

What Is the Density of 403 Stainless Steel?

Type 403 stainless steel, a martensitic grade, has a density of approximately 7,700 kg/m³. It's known for its heat resistance and mechanical properties.