15 years one-stop China custom CNC machining parts factory

267 |

Published by VMT at Oct 25 2024

267 |

Published by VMT at Oct 25 2024

In the world of sheet metal fabrication, choosing the right material is crucial to ensuring durability, cost-efficiency, and the desired performance of the final product. Two common materials that are often compared are Galvanneal steel and Galvanized steel. Both materials have undergone galvanization processes, which provide corrosion resistance by coating steel with zinc. However, the manufacturing processes, properties, and ideal applications for each material vary significantly. Understanding these differences is key to selecting the best material for your project, particularly in industries like automotive, construction, and energy, where material properties can affect safety, longevity, and cost. This guide will dive deep into the specifics of Galvanneal and Galvanized steel, comparing their characteristics, advantages, disadvantages, and common uses.

Galvanizing is a process in which steel is coated with a layer of zinc to protect it from corrosion. The zinc coating acts as a barrier, preventing moisture and oxygen from reaching the steel beneath. Several methods are used to galvanize steel, with hot-dip galvanizing being the most common for both Galvanneal and Galvanized steel. Other galvanizing methods include thermal spraying, electrogalvanizing, and sherardizing. Each process has its own advantages and is suited to different applications. Understanding the specific method of galvanizing can help in determining which type of steel is best for your needs.

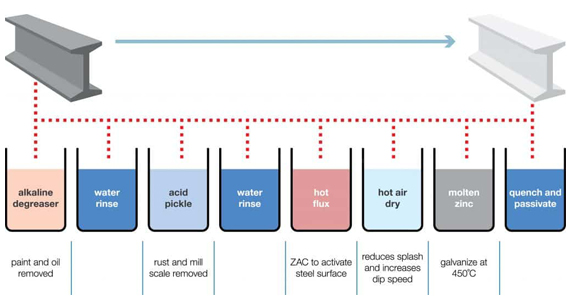

Hot-Dip Galvanizing

Hot-dip galvanizing involves immersing steel in molten zinc to create a protective coating. This is the most widely used galvanizing method because it produces a thick, durable layer of zinc that offers excellent corrosion resistance. The process is relatively straightforward but requires several critical steps to ensure proper adhesion and longevity of the coating.

Step #1: Cleaning

The steel must first be thoroughly cleaned to remove any dirt, oil, or rust that could interfere with the adhesion of the zinc. This step typically involves degreasing or cleaning with alkaline solutions, followed by rinsing.

Step #2: Pickling

After cleaning, the steel is immersed in a hot acid bath, usually hydrochloric or sulfuric acid, to remove mill scale, rust, and other surface impurities. This process ensures the steel's surface is completely clean and ready for the zinc coating.

Step #3: Fluxing

Fluxing is a critical step that prepares the clean steel for immersion in the molten zinc bath. A flux solution, typically zinc ammonium chloride, is applied to the steel to prevent oxidation before galvanizing. This step ensures a strong bond between the steel and the zinc.

Step #4: Galvanizing

The cleaned and fluxed steel is immersed in a bath of molten zinc, typically heated to around 450°C (840°F). The steel is submerged until the zinc reacts with the surface to form a uniform coating.

Step #5: Post-Processing

Once the steel is removed from the zinc bath, it undergoes a cooling process. In some cases, additional treatments such as quenching, passivation, or coating thickness measurement may be performed to ensure the coating meets the required specifications.

While hot-dip galvanizing is the most common method, other techniques are also used to achieve similar protective results. These processes are often used for specialized applications where the typical thickness of hot-dip galvanizing may not be required, or where different properties are desired.

Thermal Spraying (or Metallizing)

Thermal spraying involves applying molten zinc to the steel surface using a spray gun. This method allows for precise control over the thickness of the zinc coating and is often used in applications where selective or localized protection is needed. It's also suitable for repair work or for treating large structures that cannot be immersed in a zinc bath.

Electrogalvanizing

Electrogalvanizing uses an electrical current to deposit a thin layer of zinc onto the steel. This method produces a smoother and more uniform coating compared to hot-dip galvanizing, but the zinc layer is generally thinner, resulting in less corrosion protection. Electrogalvanized steel is commonly used in applications that require good surface finish but are less exposed to harsh environments, such as automotive body panels.

Sherardizing

Sherardizing is a process that involves heating steel components in a sealed rotating drum with zinc powder. The zinc bonds to the steel through diffusion, creating a corrosion-resistant layer. This method is typically used for small parts like fasteners and fittings.

Advantages of Galvanizing (Hot-Dip Galvanizing)

Hot-dip galvanizing offers numerous benefits, making it a popular choice for various industries. The process produces a robust, long-lasting coating that requires minimal maintenance, making it ideal for both structural and outdoor applications.

Less Maintenance, Low Long-Term Costs

Once steel is galvanized, the protective zinc coating requires very little maintenance. The longevity of the zinc coating means less frequent replacements or repairs, translating to lower long-term costs.

Long Service Life

Hot-dip galvanizing offers a significantly longer service life compared to untreated steel. In most environments, galvanized steel can last for decades without significant corrosion.

Strong, Reliable Coating

The metallurgical bond created during the hot-dip galvanizing process produces a coating that is tough and abrasion-resistant, capable of withstanding mechanical damage during transportation and installation.

Automatic Protection

Galvanized steel provides self-healing properties for small scratches and abrasions, thanks to the sacrificial nature of zinc. The zinc will corrode first, protecting the steel beneath.

Galvanneal steel is produced by taking hot-dip galvanized steel and subjecting it to an annealing process. This additional heat treatment transforms the zinc coating into a zinc-iron alloy layer, which significantly improves the material's paint adhesion and overall formability. The result is a smooth, matte finish that is highly sought after in industries where surface appearance and paintability are crucial.

Hot-Dip Galvanizing Annealing

In Galvanneal steel, after the steel is hot-dip galvanized, it is heated to around 500°C (932°F) to cause a diffusion reaction between the steel and the zinc, forming a zinc-iron alloy. This alloy offers better surface properties than pure zinc, especially in terms of paint adhesion.

Continuous Galvanizing

Continuous galvanizing is a method of producing Galvanneal steel by passing the steel through a continuous galvanizing line. This process allows for high-speed production, making Galvanneal steel widely available for automotive and construction applications.

Advantages of Galvanneal Steel

Excellent Paint Adhesion

One of the primary benefits of Galvanneal steel is its excellent paint adhesion. The zinc-iron alloy surface is more receptive to paints and coatings than traditional galvanized steel, making it a popular choice in applications where painting or finishing is necessary.

High Formability

Galvanneal steel has better formability compared to standard galvanized steel. This makes it easier to shape and mold into complex forms without cracking or losing its protective properties, which is especially useful in the automotive industry.

Smooth Matte Finish

The matte finish of Galvanneal steel provides a clean, uniform appearance, making it ideal for applications where aesthetics are important.

Disadvantages of Galvanneal Steel

Lower Corrosion Resistance

Despite its many advantages, Galvanneal steel has slightly lower corrosion resistance compared to galvanized steel. The zinc-iron alloy is less effective at protecting the underlying steel from harsh environmental conditions, especially in marine or high-humidity environments.

Higher Cost

The annealing process and the superior surface properties of Galvanneal steel often make it more expensive than galvanized steel. This additional cost needs to be weighed against the benefits in applications where paintability and formability are essential.

Susceptible to High Temperatures

Galvanneal steel can lose its protective properties when exposed to high temperatures for prolonged periods, making it less suitable for applications that involve extreme heat.

Typical Uses of Galvanneal Steel Products

Galvanneal steel is widely used in industries where paintability, appearance, and formability are critical factors. Common applications include automotive body parts, electrical cabinets, and waste disposal containers.

Automotive Industry

The automotive industry is one of the largest users of Galvanneal steel, particularly for body panels and other components that require excellent paint adhesion and formability.

Waste Disposal

Galvanneal steel is also used in the manufacturing of waste disposal containers due to its formability and ability to be easily painted for aesthetic purposes.

Galvanized steel is widely used in various industries due to its excellent corrosion resistance and cost-effectiveness. The zinc coating provides a durable, protective barrier that extends the life of the steel.

Hot-Dip Galvanizing

Hot-dip galvanizing is the most common method for producing galvanized steel. It involves immersing steel in molten zinc, forming a thick, protective coating that guards against rust and corrosion.

Electrogalvanizing

Electrogalvanizing, on the other hand, uses an electrical current to deposit zinc onto the steel surface. This method produces a thinner, more uniform coating, which is ideal for applications where a smoother finish is required.

Advantages of Galvanized Steel

Long Life

Galvanized steel offers a long service life, even in harsh outdoor environments. The zinc coating provides excellent corrosion protection, extending the life of the steel.

Low Maintenance

Once galvanized, the steel requires minimal maintenance, which reduces the overall lifecycle costs of the product.

Economically Efficient

Compared to other corrosion-resistant coatings, galvanizing is relatively cost-effective, making it a popular choice for large-scale industrial applications.

Disadvantages of Galvanized Steel

Limited Color Options

One downside to galvanized steel is its limited aesthetic flexibility. The zinc coating typically results in a gray or silver finish, which may not be suitable for applications where color customization is required.

Poor Weldability

The zinc coating on galvanized steel can cause issues during welding, including the release of toxic fumes. Special precautions must be taken to safely weld galvanized steel.

Not Suitable for High Temperature Applications

Galvanized steel is not ideal for high-temperature applications, as the zinc coating can deteriorate when exposed to extreme heat.

Typical Uses of Galvanized Steel Products

Galvanized steel is used in a wide range of industries due to its durability and corrosion resistance. Some of the most common applications include construction, automotive, and energy sectors.

In the automotive industry, galvanized steel is used for underbody parts, frames, and other components that are exposed to moisture and salt.

Nuts, Bolts, and Other Tools

Galvanized steel is commonly used in the production of nuts, bolts, and other fasteners due to its strength and corrosion resistance.

Construction Industry

The construction industry frequently uses galvanized steel for structural components, roofing, and outdoor fixtures.

Energy Industry

In the energy sector, galvanized steel is used for power transmission towers, poles, and other outdoor infrastructure that requires long-lasting corrosion protection.

Agriculture Industry

Galvanized steel is also a popular choice in the agriculture industry for fencing, silos, and other outdoor equipment that must withstand harsh weather conditions.

When comparing Galvanized and Galvanneal steel, it is essential to consider the differences in their manufacturing processes, coating properties, and performance characteristics. Each material offers unique advantages depending on the application.

1. Manufacturing Process

Both materials begin with hot-dip galvanizing, but Galvanneal steel undergoes an additional annealing step, which alters the zinc coating into a zinc-iron alloy.

2. Coating

Galvanized steel has a pure zinc coating, while Galvanneal steel features a zinc-iron alloy. This difference affects their corrosion resistance, paintability, and overall performance.

3. Properties

Properties of Galvanized Steel

Corrosion Resistance: Galvanized steel offers excellent corrosion resistance due to the thick zinc coating.

Strength: Galvanized steel retains the strength of the underlying steel while providing a durable, protective coating.

Ductility: Galvanized steel can be shaped and bent, although it is less formable than Galvanneal steel.

Weldability: The zinc coating can complicate welding, requiring special precautions to avoid toxic fumes.

Properties of Galvanneal Steel

Enhanced Paintability: Galvanneal steel's zinc-iron alloy coating provides superior paint adhesion.

Improved Formability: Galvanneal steel is easier to form and shape than standard galvanized steel, making it ideal for complex parts.

Reduced Coating Thickness: The annealing process results in a thinner coating, which may offer less corrosion resistance but better surface finish.

Flake-Free Surface: Galvanneal steel has a smooth, matte finish with no zinc flaking, which is ideal for painted surfaces.

4. Appearance

Galvanneal steel has a smooth, matte finish, while galvanized steel typically has a more textured, spangled appearance due to the crystalline structure of the zinc coating.

5. Applications

Applications of Galvanized Steel

HVAC Systems: Galvanized steel is used for ductwork and other HVAC components due to its corrosion resistance.

Agriculture: Galvanized steel is commonly used for fencing, silos, and barns.

Industrial Applications: Galvanized steel is used in a wide range of industrial applications, from storage tanks to outdoor equipment.

Applications of Galvanneal Steel

Automotive Industry: Galvanneal steel is widely used in the automotive industry for body panels and other components that require good paint adhesion and formability.

Appliance Manufacturing: The smooth, paintable surface of Galvanneal steel makes it ideal for use in appliances such as refrigerators and washing machines.

Electrical Systems: Galvanneal steel is used in the production of electrical cabinets and enclosures.

6. Cost

Galvanized steel is typically less expensive than Galvanneal steel due to the additional annealing process required for Galvanneal. However, the higher cost of Galvanneal steel may be justified in applications where superior paintability and formability are required.

Choosing between Galvanized and Galvanneal steel depends on the specific requirements of your project. If corrosion resistance and cost are your primary concerns, galvanized steel may be the better choice. However, if paint adhesion and formability are critical, Galvanneal steel may be worth the extra investment. Both materials have their strengths and are widely used in various industries, from automotive to construction. Working with a trusted CNC machining factory can help you determine which material is best suited for your needs.

Are Galvanized and Stainless Steel the Same?

No, galvanized steel is coated with zinc, while stainless steel contains chromium, which provides inherent corrosion resistance without the need for a coating.

Can Galvanized Steel and Stainless Steel be Used Together?

Yes, but precautions must be taken to prevent galvanic corrosion, which can occur when dissimilar metals are in contact.

Is Galvanized Steel Stronger Than Regular Steel?

Galvanized steel has the same strength as regular steel but with added corrosion resistance due to the zinc coating.

What is the Difference Between GI and GA?

GI (Galvanized Iron) refers to steel that is hot-dip galvanized, while GA (Galvanneal) steel is galvanized and then annealed to improve paint adhesion.

Is Galvanized Steel Magnetic?

Yes, galvanized steel is magnetic, as the zinc coating does not affect the magnetic properties of the underlying steel.

What is the Galvanizing Temperature?

The typical temperature for hot-dip galvanizing is around 450°C (840°F).

Is Electrogalvanizing Better Than Hot-Dip Galvanizing?

Electrogalvanizing produces a smoother finish but offers less corrosion protection compared to hot-dip galvanizing.

Will Galvanized Steel Rust After Welding?

Yes, welding galvanized steel can expose the underlying steel, leading to rust. It's important to protect the welded areas with a zinc-rich coating.

By comparing the two materials—Galvanneal and Galvanized steel—you can make informed decisions for your project. This guide has covered their respective properties, advantages, and typical uses, equipping you with the knowledge to choose the right material for your specific application. Whether you're working in the automotive industry or looking to build durable construction components, Galvanneal and Galvanized steel offer solutions that cater to different needs.