15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

509 |

Published by VMT at Oct 26 2024 | Reading Time:About 2 minutes

509 |

Published by VMT at Oct 26 2024 | Reading Time:About 2 minutes

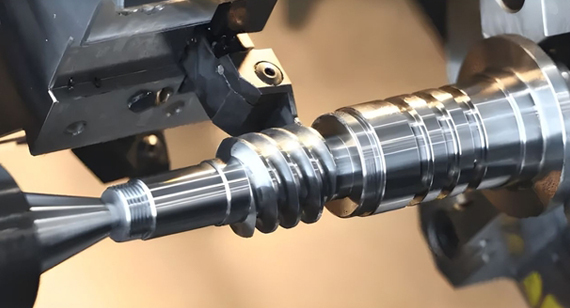

CNC lathe grooving is a specialized machining process used to create grooves and slots in various materials, enhancing the functionality and aesthetics of parts. This process leverages advanced CNC technology to achieve high precision and repeatability, making it a vital operation in the manufacturing of components across diverse industries. Understanding the different types of grooving tools available, along with the methods and considerations for effective use, is essential for optimizing machining performance and ensuring high-quality results.

Grooving is a machining process that involves removing material from a workpiece to create a narrow groove or slot. This operation is commonly performed on CNC lathes, where rotating workpieces are cut by stationary or rotating tools. The primary purposes of grooving include creating space for assembly, enhancing part functionality, and improving aesthetics. The precision offered by CNC lathe grooving makes it suitable for a wide range of applications, including aerospace, automotive, and industrial manufacturing.

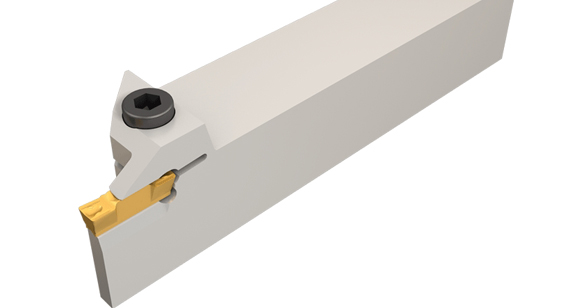

Grooving tools come in various designs, each tailored for specific applications and workpiece geometries. Understanding the types of grooving tools is crucial for selecting the right tool for a given project, ensuring optimal performance and desired results.

Face Grooving Tools

Face grooving tools are designed to cut grooves on the face of a workpiece. These tools are commonly used for operations that require the creation of grooves for sealing surfaces, assembly interfaces, or decorative elements. Face grooving tools typically feature a flat cutting edge and are used in conjunction with a CNC lathe's face milling capabilities. Their design allows for efficient material removal and smooth surface finishes, making them ideal for applications that require high precision.

OD Grooving Tools

Outer diameter (OD) grooving tools are used to create grooves on the external surfaces of cylindrical workpieces. These tools are particularly useful for machining features like keyways, grooves for O-rings, and other external profiles. OD grooving tools come in various shapes and sizes to accommodate different groove dimensions and depths. Their ability to operate on the outer diameter makes them essential for producing parts with complex geometries and enhanced functional properties.

ID Grooving Tools

Internal diameter (ID) grooving tools are specifically designed for creating grooves on the internal surfaces of hollow components. These tools allow for the machining of features such as internal threads, grooves for seals, and other interior profiles. ID grooving tools are often longer and more slender than their OD counterparts, enabling them to reach into narrow spaces within the workpiece. This capability makes them crucial for applications in industries such as plumbing, automotive, and aerospace, where internal grooves and profiles are often required.

Performing grooving operations on a CNC lathe requires careful preparation and setup to ensure accuracy and efficiency. Following a systematic approach can significantly enhance the success of the machining process.

1. Fix the Workpiece

Start by securely mounting the workpiece on the CNC lathe's chuck or fixture. Ensuring the workpiece is firmly held prevents movement during machining, which can lead to inaccuracies and poor surface finishes. Use appropriate clamping tools and techniques to achieve a stable setup.

2. Load the Tool Equipment

Next, load the chosen grooving tool into the CNC lathe's tool holder. Verify that the tool is correctly installed and aligned to prevent issues during machining. It's crucial to ensure that the tool's cutting edges are sharp and in good condition, as this will affect the quality of the slot being cut.

3. Set Up Your CNC Lathe

Configure the CNC lathe settings according to the specifications of the project. Input the correct feed rates, cutting speeds, and depth of cut into the CNC controller. This setup is essential for achieving the desired slot dimensions and ensuring optimal material removal rates.

4. Enter and Run the Program

Once the setup is complete, enter the machining program into the CNC lathe. This program should outline the tool path, speed, and feed rates for the grooving operation. Conduct a dry run without material to ensure that the tool moves correctly through the desired path.

5. Clean Up

After completing the grooving operation, clean the work area and remove any chips or debris generated during machining. Regular cleaning helps maintain a safe and efficient work environment and ensures the CNC lathe operates smoothly.

Note: It is very important to check the depth of the groove before starting to cut and use cutting oil to prevent deformation.

CNC lathes are capable of performing various grooving operations, each suited for specific applications and geometries. Understanding these operations allows for more effective use of grooving tools and enhanced machining capabilities.

External Grooving

External grooving involves cutting grooves on the outer surface of a workpiece. This operation is commonly used for features such as keyways, O-ring grooves, and decorative patterns. There are three types of external grooving:

Single Grooving: A straightforward operation that creates one groove in a single pass.

Multiple Grooving: Involves cutting several grooves simultaneously, enhancing productivity and efficiency.

Ramps: This technique allows for the creation of sloped or angled grooves, which can be useful for specific functional requirements.

Internal Grooving

Internal grooving focuses on creating grooves within hollow components. This operation is essential for applications requiring internal features such as threads or seals.

Face Grooving

Face grooving involves cutting grooves on the face of a workpiece, similar to face grooving but often for different applications, such as creating pockets or decorative elements.

Choosing the right grooving tool is vital for achieving the desired results in CNC lathe grooving. Several factors should be considered:

1. Grooving Type

Different grooving operations require specific tool designs. Understanding the type of groove needed helps in selecting the appropriate tool geometry and cutting edge configuration.

2. Workpiece Material

The material being machined affects tool selection. Harder materials may require more robust tools or special coatings to enhance tool life and performance.

3. Required Shape

The shape of the groove is another critical factor. Whether a simple straight groove or a complex profile, selecting the right tool design is essential for achieving accuracy and efficiency.

Enhancing grooving operations can lead to improved productivity and part quality. Here are several strategies to consider:

1. Inspection and Measurement Procedures

Implementing rigorous inspection and measurement protocols ensures that the grooved features meet specifications. Regularly checking tool wear and part dimensions can help identify issues early on.

2. Feed Rates and Cutting Speeds

Optimizing feed rates and cutting speeds can significantly impact the quality of the grooves. Higher speeds may improve efficiency, but they should be balanced with the material’s properties to avoid tool damage or poor finishes.

3. Grooving Tool Selection

Selecting the right tool for the specific application is crucial. Consider factors such as tool geometry, coating, and material compatibility to enhance performance and tool life.

Understanding the types of grooving tools and their applications is essential for effective CNC lathe grooving. By carefully selecting the right tools and following best practices in setup and operation, manufacturers can achieve high-quality results and improve overall machining efficiency. Whether for creating grooves, slots, or specialized features, the right approach can enhance the performance of CNC machining parts across various industries.

What are the different types of grooving?

Grooving can include external, internal, and face grooving, each serving different applications.

What is the difference between a cut-off tool and a grooving tool?

A cut-off tool is used to sever a workpiece, while a grooving tool creates narrow cuts or slots.

What is the difference between an OD grooving tool and a cut-off tool?

OD grooving tools create grooves on the outside of a workpiece, whereas cut-off tools are designed for cutting through material.

What is the difference between a slot and a groove?

A slot typically refers to a longer, narrower opening, while a groove can be a broader term encompassing various shapes and depths.

What type of material is best for making grooving tools?

High-speed steel (HSS) and carbide are commonly used materials due to their hardness and wear resistance.

Do grooving tools need coatings?

Coatings can enhance the performance of grooving tools by reducing friction and wear, especially when machining difficult materials.

What are the different types of roll grooving?

Roll grooving techniques vary based on the application and material, with options including full-round and partial-round grooves.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!