15 years one-stop China custom CNC machining parts factory

464 |

Published by VMT at Dec 01 2024 | Reading Time:About 10 minutes

464 |

Published by VMT at Dec 01 2024 | Reading Time:About 10 minutes

CNC machining stainless steel is a popular process for creating durable, high-performance parts used across industries like aerospace, medical, automotive, and manufacturing. However, while stainless steel is known for its superior corrosion resistance, strength, and aesthetic appeal, machining it can be a real challenge. The material's hardness, tendency to work-harden, and high heat generation during processing require advanced techniques, specialized tools, and deep knowledge to produce high-quality parts. If you're working with stainless steel, understanding the unique challenges, tips, types, and advantages of CNC machining stainless steel will help you overcome these hurdles and get the most out of this material for your projects.

CNC machining stainless steel parts comes with its own set of challenges, including high heat generation, tool wear, and machining precision. Specialized techniques like managing heat and using the right cutting tools can help overcome these issues. Choosing the right grade of stainless steel and machining method is essential for achieving high-quality results, making custom CNC machining services crucial for complex stainless steel parts.

Understanding the challenges of CNC machining stainless steel is the first step in mastering the process. In this article, we will delve deeper into the specific difficulties involved, explore the types of stainless steel used in CNC machining, and provide useful tips to improve the process. Let's begin by discussing the qualities of stainless steel and why it's a preferred material for CNC machining in the first place.

Stainless steel is a versatile, corrosion-resistant alloy made primarily of iron, carbon, and a minimum of 10.5% chromium. The chromium in stainless steel forms a passive layer of chromium oxide on the surface of the steel, which prevents rust and corrosion. It is an incredibly durable material known for its resistance to heat, corrosion, and wear, making it a preferred choice for industries where longevity, hygiene, and aesthetic appeal are essential.

Stainless steel is available in various grades, each with unique properties suited to different applications. From medical devices to automotive parts, stainless steel offers an excellent balance of strength, resistance to oxidation, and formability. However, despite its many advantages, machining stainless steel can be quite challenging due to its physical properties. High hardness, low thermal conductivity, and work-hardening tendencies require special care when machining.

Stainless steel is often the material of choice for CNC machining parts due to its range of beneficial properties. Below, we explore why stainless steel is favored for CNC machining, particularly for custom applications:

1. High Tensile Strength

Stainless steel boasts exceptional tensile strength, meaning it can withstand significant stress and tension without breaking. This makes it ideal for applications where durability is key, such as in aerospace, automotive, and medical industries. The high tensile strength also makes it more challenging to machine, but the result is a part that can endure harsh conditions.

2. Low Temperature Resistance

Stainless steel is known for maintaining its strength and structural integrity at low temperatures, making it ideal for use in environments subject to extreme cold. This is why stainless steel is commonly used in industries such as cryogenics, refrigeration, and aerospace.

3. Corrosion Resistance

One of the primary reasons stainless steel is chosen for CNC machining is its exceptional resistance to corrosion. The chromium in stainless steel prevents rust, oxidation, and staining, even when exposed to harsh chemicals, moisture, and salt. This makes it a go-to material for parts that must withstand harsh environments, such as medical implants, marine equipment, and industrial components.

4. Aesthetic Appeal

Stainless steel has a shiny, appealing finish, making it ideal for products that require not only functional performance but also aesthetic value. This makes it popular in high-end consumer goods like kitchen appliances, jewelry, and decorative elements.

5. Designed for Improved Machinability

While stainless steel is known for its challenges during machining, it also comes in different grades that offer improved machinability. For instance, grades like 303 stainless steel are specifically engineered to be easier to machine, making them more suitable for projects requiring CNC machining.

6. Low Cost

Though more expensive than carbon steel, stainless steel is still relatively affordable given its durability and versatility. The cost of stainless steel is outweighed by the long-term benefits, especially for parts that need to withstand extreme conditions or offer longevity.

7. Fast Part Turnaround

Stainless steel parts can be manufactured relatively quickly, thanks to modern CNC machining technologies. CNC machining allows for fast and precise manufacturing, which is critical when producing complex stainless steel parts that require tight tolerances and rapid production timelines.

Despite its many advantages, CNC machining stainless steel presents several challenges, primarily related to the material's hardness, machinability, and tendency to work-harden. Here are some of the key difficulties faced by manufacturers when working with stainless steel:

1. Overheating

Stainless steel has poor thermal conductivity, meaning heat tends to build up during machining rather than dissipating. This can lead to overheating, which damages cutting tools, compromises the part’s surface finish, and accelerates tool wear. Managing heat is crucial to prevent deformation and maintain the integrity of both the tools and the workpiece.

2. Difficult Surface Finishes

Achieving a smooth surface finish on stainless steel can be challenging due to its hardness and tendency to form burrs. The material can easily become scratched or marred during machining, making it difficult to achieve a high-quality, aesthetically pleasing surface finish, especially for products intended for consumer-facing applications.

3. Technical Expertise

Machining stainless steel requires significant expertise in both the material properties and the CNC machining process. Operators must have a deep understanding of factors like cutting speed, tool selection, coolant use, and feed rate to optimize machining operations and avoid issues like excessive tool wear and part deformation.

4. Poor Machinability

Certain grades of stainless steel, such as 304 and 316, are known for their poor machinability. These alloys can be difficult to machine due to their work-hardening tendencies, which cause the material to become harder the more it is cut. This can lead to increased tool wear, longer machining times, and the need for specialized equipment and cutting techniques.

5. Avoid Workpiece Deformation

Stainless steel parts are prone to warping and deformation during machining, especially when the material is thin or has complex geometries. This requires careful attention to clamping, tool selection, and machining parameters to avoid damaging the workpiece.

To effectively machine stainless steel, certain strategies can help mitigate common issues like overheating, tool wear, and poor surface finishes. Here are some tips to improve your CNC machining process:

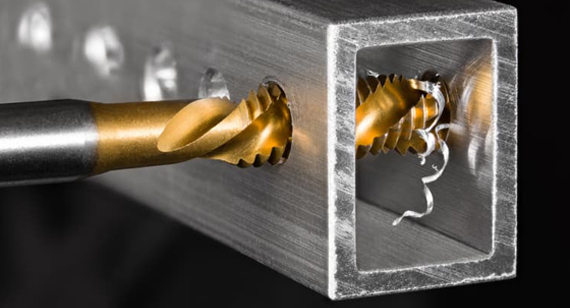

1. Choosing Specialized End Mills and Drills

Using the right cutting tools is essential for machining stainless steel. End mills and drills made from materials like carbide or cobalt are often the best choices due to their strength and wear resistance. Coated tools can also help reduce friction and heat generation.

2. Managing the Heat Generated

Since stainless steel retains heat poorly, cooling is essential during machining. Using a high-quality coolant or lubricant can help dissipate heat, extend tool life, and improve surface finishes. Additionally, optimizing the feed rate and cutting speed can help manage heat buildup.

3. Using Peck Drilling and Chip Breaking Cycles

Peck drilling involves breaking the drilling process into smaller, more manageable steps, allowing for better chip removal and heat dissipation. Chip breaking cycles are similarly important for reducing the chances of chips getting stuck, which can affect machining accuracy.

4. Protecting the Workpiece from Deformation

To prevent distortion, it's important to securely clamp the workpiece during machining. Additionally, using slower feed rates and controlling cutting forces can help avoid introducing stresses that might cause warping or bending.

Stainless steel is one of the most widely used materials in CNC machining due to its exceptional strength, corrosion resistance, and versatility. However, not all stainless steel is the same. There are several different grades of stainless steel, each with its unique properties and applications. When choosing a stainless steel grade for CNC machining, it’s essential to understand the differences between these grades, as each offers distinct advantages and challenges. This article explores the different types of stainless steel commonly used in CNC machining, including austenitic, martensitic, ferritic, duplex, and precipitation-hardening stainless steels.

Understanding these categories will help manufacturers and engineers select the right material for their specific machining projects, ensuring high-quality results, reduced costs, and minimized machining difficulties.

Austenitic Stainless Steel

Austenitic stainless steel is the most common and versatile category of stainless steel. It is non-magnetic and known for its high corrosion resistance, excellent weldability, and good formability. Austenitic stainless steel is primarily composed of iron, chromium, and nickel, with trace amounts of other alloying elements such as manganese, molybdenum, and nitrogen. The inclusion of nickel is what gives austenitic stainless steels their non-magnetic properties.

Austenitic stainless steels are generally divided into two series: the 200 series (which is less commonly used) and the 300 series, which is the most popular and commonly machined category. They are prized for their ability to perform well in both highand low-temperature environments.

Austenitic Stainless Steel Examples

Properties of Austenitic Stainless Steels

Applications of Austenitic Stainless Steels

200 Grade Stainless Steel Applications: These are typically used in applications where strength and corrosion resistance are required but at a lower cost. They can be used in low-temperature applications and in situations where non-magnetic properties are important.

300 Grade Stainless Steel Applications: This series is more commonly used in demanding applications like food processing, medical devices, chemical processing, and the manufacturing of parts for the aerospace, automotive, and construction industries.

Martensitic Stainless Steels

Martensitic stainless steels are a class of stainless steel alloys known for their high hardness and strength. They have a higher carbon content than austenitic steels, which allows them to be hardened by heat treatment. However, they are generally less resistant to corrosion compared to other stainless steel types. Martensitic steels are magnetic and often used in applications where both strength and resistance to wear are required.

Examples of Martensitic Stainless Steels

Properties of Martensitic Stainless Steels

Corrosion Resistance: Martensitic stainless steels offer moderate resistance to corrosion but are more susceptible to rust than austenitic steels. They are best suited for dry environments or areas where the part will be coated for additional protection.

Applications of Martensitic Stainless Steels

Martensitic stainless steels are commonly used for applications requiring high strength and wear resistance, such as:

Ferritic Stainless Steels

Ferritic stainless steels are known for their magnetic properties and good resistance to corrosion, particularly in atmospheric and moderate environments. Unlike austenitic steels, ferritic steels do not contain nickel, and they have lower carbon content. They are primarily composed of chromium, with some adding small amounts of molybdenum or other alloying elements to enhance specific properties.

Examples of Ferritic Stainless Steels

Properties of Ferritic Stainless Steels

Corrosion Resistance: While ferritic steels are less corrosion-resistant than austenitic steels, they offer good resistance to general corrosion and are ideal for use in environments where exposure to corrosive elements is limited.

Applications of Ferritic Stainless Steels

Ferritic stainless steels are commonly used in applications such as:

Duplex Stainless Steels

Duplex stainless steels combine the characteristics of both austenitic and ferritic stainless steels. They offer enhanced strength and improved corrosion resistance compared to single-phase austenitic or ferritic steels. These alloys contain a mixture of both face-centered cubic (FCC) and body-centered cubic (BCC) crystal structures, making them ideal for applications requiring both strength and resistance to corrosion, particularly in marine and chemical environments.

Examples of Duplex Stainless Steels

Properties of Duplex Stainless Steel

Duplex stainless steels exhibit a range of beneficial properties, including excellent resistance to corrosion, good weldability, and improved toughness compared to ferritic stainless steels.

Applications of Duplex Stainless Steel

Duplex steels are widely used in:

Precipitation Hardening Stainless Steel

Precipitation hardening stainless steels are designed for high-strength applications and can be hardened through heat treatment. These steels have excellent corrosion resistance and are typically used in aerospace, military, and high-performance engineering applications.

Examples of Precipitation Hardening Stainless Steels

Properties of Precipitation Hardening Stainless Steels

These alloys offer excellent strength and corrosion resistance, making them ideal for high-performance applications.

Applications of Precipitation Hardening Stainless Steels

Precipitation hardening steels are used in:

When selecting stainless steel for CNC machining or manufacturing processes, it’s essential to understand the material’s mechanical properties. These properties directly affect the performance, durability, and machinability of the material. The most commonly used stainless steel alloys for machining include Stainless Steel 303, Stainless Steel 304, Stainless Steel 316, and Stainless Steel 17-4PH. Each of these alloys has unique characteristics that make them suited for specific applications, depending on factors such as tensile strength, elongation, and hardness.

In this section, we will compare these stainless steel alloys based on their ultimate tensile strength, elongation, and hardness, which are critical properties for evaluating their suitability for different machining and engineering applications.

Stainless Steel 303

Ultimate Tensile Strength (UTS):

Stainless Steel 303 is known for its ease of machining, making it one of the most popular alloys for parts requiring extensive machining. Its tensile strength is moderate compared to other stainless steels, making it suitable for moderate-load applications.

Elongation:

303 stainless steel exhibits a good degree of elongation, which means it can undergo significant deformation before breaking. This is crucial for applications that require some formability while retaining strength.

Hardness:

303 stainless steel has a relatively low hardness compared to other high-strength stainless steels, which further contributes to its superior machinability. It is ideal for components that require machining into complex shapes or fine tolerances, like nuts, bolts, and fittings.

Application Summary:

Stainless Steel 304

Ultimate Tensile Strength (UTS):

Stainless Steel 304 is one of the most commonly used stainless steel alloys due to its excellent balance of strength and corrosion resistance. The UTS is similar to that of 303 but is slightly higher, making it more suitable for applications with higher mechanical demands.

Elongation:

Like 303 stainless steel, 304 exhibits good elongation, indicating its ability to bend and stretch without breaking. This makes it ideal for parts that require both strength and formability.

Hardness:

304 stainless steel has a lower hardness than martensitic steels but is harder than 303. This allows for a balance of machinability and durability, making it suitable for structural applications in many industries.

Application Summary:

304 is used in a variety of industries, including food processing, medical devices, construction, automotive, and chemical processing equipment. Its resistance to oxidation and ease of welding make it ideal for most general-purpose applications.

Stainless Steel 316

Ultimate Tensile Strength (UTS):

316 stainless steel has a higher tensile strength than both 303 and 304, making it more suitable for applications requiring high mechanical strength and resistance to aggressive environments, particularly in marine and chemical applications.

Elongation:

316 also exhibits good elongation, similar to 304, which is necessary for parts that undergo deformation during machining or application use.

Hardness:

Although the hardness of 316 is lower than that of martensitic stainless steels like 17-4PH, it is still relatively high compared to 303 and 304. This gives it a good balance of strength, durability, and machinability, especially in corrosive environments.

Application Summary:

316 stainless steel is ideal for marine environments, chemical processing, pharmaceutical applications, and food handling equipment due to its enhanced corrosion resistance, particularly in chloride-rich environments.

Stainless Steel 17-4PH

Ultimate Tensile Strength (UTS):

17-4PH stainless steel, a precipitation-hardening stainless steel, boasts an extremely high tensile strength, making it one of the strongest stainless steels available. Its strength is significantly higher than that of austenitic alloys like 303, 304, and 316, which makes it suitable for highly demanding applications.

Elongation:

The elongation of 17-4PH is lower than the austenitic steels, which is typical for high-strength alloys. While it is still ductile enough for many applications, it is not as formable as 303 or 304.

Hardness:

17-4PH has a high hardness due to its precipitation hardening process, providing superior wear resistance and strength, especially in high-temperature applications.

Application Summary:

17-4PH is used in aerospace, chemical processing, marine engineering, and high-performance parts such as turbine blades, valves, gears, and shaft components.

Comparison Table: Mechanical Properties of Stanless Steel Alloys

| Property |

Stainless Steel 303 |

Stainless Steel 304 |

Stainless Steel 316 |

Stainless Steel 17-4PH |

| Ultimate Tensile Strength (MPa) |

510 |

520 |

580 |

1,260 |

| Ultimate Tensile Strength (psi) |

74,000 |

75,000 |

84,000 |

183,000 |

| Elongation (%) |

40 |

40 |

40 |

15-18 |

| Hardness (Rockwell B) |

95 |

92 |

90 |

35 (Rockwell C) |

Conclusion

When choosing between stainless steel alloys for CNC machining or manufacturing, understanding their mechanical properties—such as ultimate tensile strength, elongation, and hardness—is essential for selecting the right material for the job.

Selecting the correct stainless steel alloy depends on the specific requirements of the project, including strength, resistance to corrosion, and machinability.

Stainless steel is one of the most commonly used materials in CNC machining, known for its versatility, durability, and excellent resistance to corrosion. The wide range of stainless steel alloys available enables manufacturers to choose the most appropriate grade for their specific applications, balancing factors like machinability, strength, corrosion resistance, and cost.

In CNC machining, stainless steel alloys are typically categorized into several grades, including 17-4 PH, 302, 303, 304, and 416. Each grade has distinct characteristics that make it ideal for specific manufacturing processes and industries. Understanding these grades is essential for selecting the right material for a given CNC machining project.

In this section, we will explore some of the most commonly used stainless steel alloys in CNC machining, highlighting their advantages, disadvantages, and typical applications.

SS Grade 17-4 (PH Stainless Steel)

SS Grade 17-4 (PH) is a precipitation-hardening stainless steel alloy that is widely recognized for its high strength and excellent corrosion resistance. The alloy's name, "17-4," refers to its composition, which contains approximately 17% chromium and 4% nickel. It is heat-treated to achieve maximum strength, making it one of the highest-performing stainless steels in its category.

17-4PH stainless steel is typically hardened through a two-step aging process, resulting in improved mechanical properties. This alloy is a martensitic stainless steel, which means it can be heat-treated to achieve high tensile strength and hardness. It is often used in critical applications where both strength and resistance to corrosion are required.

Advantages:

Disadvantages:

Applications:

SS Alloy 302

SS302 is a general-purpose austenitic stainless steel alloy with high corrosion resistance and good weldability. It is commonly used in industrial applications where moderate strength and excellent resistance to oxidation are required. SS302 is essentially a variant of the more common SS304, with a slightly higher carbon content that allows for improved strength properties, especially at higher temperatures.

Advantages:

Disadvantages:

Applications:

SS303 (Easy-to-machine Stainless Steel)

SS303 is a free-machining stainless steel alloy that is commonly used in CNC machining due to its excellent machinability. It is a variation of the standard SS304 alloy with the addition of sulfur or phosphorus to improve the material's machinability. This makes SS303 a popular choice for high-volume production runs where efficiency and cost-effectiveness are key considerations.

Advantages:

Disadvantages:

Applications:

SS Alloy 304 (Stainless Steel)

SS304 is one of the most widely used stainless steel alloys and is a type of austenitic stainless steel. It is composed of 18% chromium and 8% nickel, providing it with excellent corrosion resistance, high strength, and good weldability. SS304 is an ideal choice for a wide range of applications, particularly those requiring exposure to moderate to severe corrosive environments.

Advantages:

Disadvantages:

Applications:

SS Alloy 416 (Easy-to-machine Stainless Steel)

SS416 is a martensitic stainless steel that is specifically designed for superior machinability. It contains sulfur, which is added to enhance the material's ability to be machined, making it suitable for parts that require precision manufacturing with minimal tool wear. SS416 provides a balance of good corrosion resistance and excellent machinability, making it suitable for various mechanical applications.

Advantages:

Disadvantages:

Applications:

|

Alloy |

Type |

Description |

Advantages |

Disadvantages |

Applications |

| SS 303 |

Free Machining Stainless Steel |

One of the most readily available and highly machinable of all austenitic grades of stainless steel. |

Excellent machinability, good corrosion resistance, moderate cost. |

Cannot be hardened by heat treatment. Not suitable for marine applications. |

Electronic hardware, nuts and bolts, screws, aircraft fittings, bushings. |

| SS 416 |

Free Machining Stainless Steel |

Offers superior machinability to any other stainless steel. |

Outstanding machinability, moderate corrosion resistance, good strength. |

Not suitable for chlorine or marine environments. Poor weldability and limited availability. |

Valves, pump shafts, gears, nuts, bolts. |

| SS 304 |

Stainless Steel |

One of the most common stainless steels alloys available with good weldability. |

Good machinability, weldability, and cost. Excellent corrosion resistance. |

Susceptible to stress corrosion cracking in some applications above 60°C. Some other stainless steel alloys offer better resistance to pitting and crevice corrosion. |

Food handling, utensils, automotive parts, architectural applications, heat exchangers, screws. |

| SS Grade 17-4 |

PH Stainless Steel |

It is a grade of martensitic precipitation-hardened stainless steel, containing up to 30% chromium. |

Very high toughness, strength, and corrosion resistance. |

Requires efficient and careful heat treatment. |

Nuclear reactors, aircraft turbines, oil and gas applications. |

Conclusion

Each stainless steel alloy offers distinct advantages and trade-offs depending on the specific requirements of the application. While alloys like SS303 and SS416 excel in machinability, materials like SS304 and SS316 are better suited for corrosion-resistant applications. Alloys like 17-4PH provide high strength and toughness for critical industrial applications, while SS302 is a versatile general-purpose stainless steel.

When selecting stainless steel for CNC machining, it's important to consider the alloy's mechanical properties, machinability, corrosion resistance, and cost to ensure it aligns with the specific needs of the project.

CNC (Computer Numerical Control) machining is one of the most precise and efficient methods for manufacturing stainless steel parts, whether for prototypes or mass production. Stainless steel, with its durability, corrosion resistance, and high strength, is widely used in a variety of industries, including aerospace, medical devices, automotive, and manufacturing. However, due to its hardness and toughness, stainless steel can present significant challenges during machining.

This section will cover the different CNC machining processes commonly used for stainless steel, highlighting their applications, advantages, and potential challenges.

CNC Milling

CNC milling is one of the most versatile and widely used machining processes for stainless steel. In this process, a rotating cutting tool is moved along various axes to remove material from a workpiece. CNC milling can produce complex shapes, slots, holes, and surface finishes with high precision. Stainless steel is often machined using CNC milling for parts such as engine components, housings, and medical devices.

Advantages:

Challenges:

CNC Turning is a CNC machining process that uses a rotating workpiece and a stationary cutting tool to remove material. It is commonly used for creating cylindrical or conical shapes, such as shafts, bolts, and valve stems. CNC turning of stainless steel is ideal for parts that require rotational symmetry and precision.

Advantages:

Challenges:

CNC Drilling is used to create holes in stainless steel parts. CNC drilling machines use rotating drill bits to cut precise holes. Stainless steel can be drilled using various types of drill bits, including twist drills, spade drills, and step drills. Drilling is commonly used for creating holes in parts for fasteners or fluid flow systems.

Advantages:

Challenges:

Threading is a CNC machining process used to create internal or external threads on a stainless steel part. Threads are critical for parts that require fasteners or screw-based connections. Threading is typically performed using taps or thread mills, depending on the complexity of the thread profile.

Advantages:

Challenges:

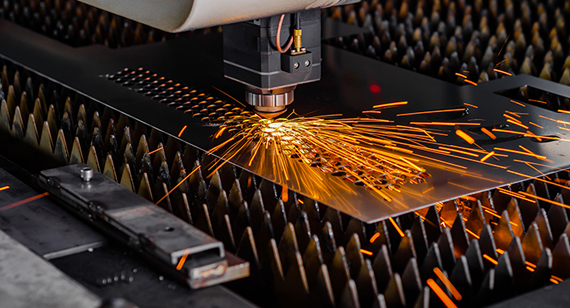

Laser cutting uses a focused laser beam to cut through stainless steel. This process is highly precise and is often used to cut intricate shapes and profiles from thin to moderately thick sheets of stainless steel. Laser cutting is especially useful for creating parts with complex geometries, such as brackets, panels, or perforated sheets.

Advantages:

Challenges:

CNC Grinding is a precision finishing process used to smooth and refine stainless steel surfaces. It uses rotating abrasive wheels or belts to remove small amounts of material, producing a fine finish. CNC grinding is used for applications where high surface finishes and tight tolerances are needed, such as precision gears, shafts, and molds.

Advantages:

Challenges:

EDM (Electrical Discharge Machining)

EDM is a process where electrical sparks are used to erode material from the workpiece. This process is typically used for machining complex shapes and hard-to-machine materials, such as stainless steel. EDM is highly effective for creating precise cavities, fine contours, and intricate shapes, especially in high-performance industries.

Advantages:

Challenges:

Water Jet Cutting

Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through stainless steel. This process is ideal for cutting thick materials without generating heat, which helps to maintain the material’s integrity. Water jet cutting can create complex shapes with minimal heat-affected zones.

Advantages:

Challenges:

Yes, stainless steel can be challenging to machine. Its hardness, toughness, and tendency to work-harden make it more difficult to cut compared to other materials like aluminum or mild steel. Machining stainless steel often requires higher cutting forces, special tooling, and effective cooling to manage the heat generated during cutting.

While some stainless steels are easier to machine than others, the material's inherent properties—especially in grades like 316 and 304—make it a demanding material for precision machining.

Machining stainless steel can present several challenges due to the material’s unique characteristics. These challenges include high tool wear, heat generation, and difficulties in achieving smooth surface finishes. Below, we outline some of the most common problems encountered during stainless steel machining.

Shortened Tool Life

Due to its hardness and toughness, stainless steel can rapidly wear down cutting tools. The cutting edges of tools can become dull, leading to decreased precision and increased production time. Specialized coatings and tools made from carbide, ceramic, or cubic boron nitride (CBN) can help mitigate this issue, but tool life remains a concern.

Difficult Machining

Stainless steel's tendency to work-harden when machined can make the process difficult. The material hardens in response to deformation, requiring more energy and higher cutting forces. This can lead to challenges in controlling the cutting process, especially in deep cuts or intricate geometries.

Poor Operator Control of Cutting

Due to stainless steel's tendency to work-harden and its high cutting forces, maintaining proper cutting conditions becomes critical. Even slight variations in tool speed, feed rates, and coolant usage can lead to poor finishes, excessive tool wear, or even part failure.

Hardness

The hardness of stainless steel, particularly in alloys like 304 and 316, can significantly affect the machinability. Harder stainless steels require more power to machine, leading to increased heat generation, which may negatively impact both the tooling and the workpiece.

Some stainless steel alloys are harder and more challenging to machine than others. 316 and 304 stainless steels, for instance, are particularly difficult due to their work-hardening properties. Higher-carbon steels or stainless steels with higher alloy contents (such as molybdenum or nickel) are even more difficult to machine.

Which Stainless Steel Is Easiest to Machine?

SS303 is one of the easiest stainless steels to machine due to its addition of sulfur, which improves its machinability. It is commonly used for parts that require high-speed machining or where intricate shapes are necessary. SS416 is another grade known for its machinability, though it has lower corrosion resistance compared to other stainless steels.

While stainless steel can be a challenging material to machine, there are several tips and strategies that can simplify the process. By using the right materials, tools, and techniques, machinists can overcome the difficulties posed by stainless steel and achieve optimal results.

Choosing High-Quality Materials

Using high-quality stainless steel with consistent properties can help avoid machining difficulties. Poor-quality material may have inconsistent hardness, leading to unpredictable machining performance.

Work Hardening

To avoid work hardening, it's essential to maintain consistent cutting speeds and feed rates. Lower cutting speeds can increase the chances of work hardening, while too high of a speed can cause excessive heat buildup.

Rigid Tools

Using rigid tooling systems can help improve machining efficiency and accuracy. Vibration or tool flex can increase the risk of poor finishes and premature tool wear.

Tool Materials

Using tools made from materials such as carbide or ceramic can improve the cutting process when machining stainless steel. These materials are much harder and can withstand the increased heat and pressure generated during machining.

Using Sharp Tools

Keeping tools sharp is essential for achieving smooth cuts and maintaining tool life. Dull tools cause excessive heat buildup and wear, leading to poor finishes and longer cycle times.

Lubricants

Lubricants, such as cutting oils or coolants, are essential for managing heat generation, reducing friction, and prolonging tool life. Coolants also help in flushing away chips, preventing them from re-entering the cutting area.

Stainless steel is an incredibly versatile material with numerous benefits that make it an ideal choice for a wide range of applications. Some of the key advantages of stainless steel include:

Corrosion Resistance

One of the most well-known properties of stainless steel is its exceptional resistance to corrosion. This makes it an ideal material for harsh environments, including marine, chemical, and food processing industries.

Shape, Cut, Join, and Weld

Stainless steel is highly malleable, making it easy to shape, cut, and join into complex structures using welding and other joining techniques.

Appearance

Stainless steel is prized for its aesthetic appeal. Its shiny surface and ability to maintain its appearance even in tough environments make it suitable for applications where both functionality and aesthetics matter.

Food Grade

Certain grades of stainless steel are FDA-approved for food contact, making them essential in industries like food processing and medical applications.

Physical Properties

Stainless steel combines strength, durability, and formability, making it useful for a wide variety of engineering applications where both strength and appearance are critical.

Durability

Stainless steel is known for its longevity and ability to perform in tough conditions. It is resistant to rust, corrosion, and wear, ensuring long service life even in demanding applications.

Recyclability

Stainless steel is highly recyclable, making it a sustainable choice for manufacturers looking to reduce their environmental impact.

Advantages

Disadvantages

When considering the cheapest stainless steel for machining, it’s important to balance cost with machinability, as well as the specific requirements of the project. Generally, the more common stainless steel grades, such as 304 and 303, tend to be more affordable due to their wide availability, relatively simple chemical composition, and proven machinability.

However, 303 stainless steel is often regarded as one of the most cost-effective and easiest-to-machine stainless steels due to its sulfur and phosphorous additions, which improve its machinability. Here's a deeper look at 303 stainless steel and other commonly used grades that are relatively inexpensive for machining:

303 Stainless Steel

303 stainless steel is a free-machining version of 304 stainless steel, designed specifically for applications that require ease of machining without sacrificing the benefits of corrosion resistance. It is one of the most affordable stainless steels for machining due to its composition and ease of cutting.

Advantages:

Disadvantages:

304 Stainless Steel

304 stainless steel, also known as "18/8 stainless steel," is another relatively inexpensive grade used in machining. While 304 stainless steel is more expensive than 303, it is still affordable compared to higher-alloyed stainless steels.

Advantages:

Disadvantages:

410 Stainless Steel

410 stainless steel is a martensitic stainless steel that is less expensive than the austenitic grades like 304 and 316. While it offers lower corrosion resistance, it has higher hardness and strength, making it suitable for specific applications where strength is more important than corrosion resistance.

Advantages:

Disadvantages:

416 Stainless Steel

416 stainless steel is another martensitic stainless steel that is designed for ease of machining. It is often used in situations where strength is important, but corrosion resistance is not the primary concern. It is cheaper and easier to machine than grades like 304 or 316.

Advantages:

Disadvantages:

Conclusion

In summary, 303 stainless steel is often considered the cheapest stainless steel for machining due to its excellent machinability and low cost. However, if corrosion resistance is more critical for the application, 304 stainless steel is a good choice, though it may come at a slightly higher cost. 410 and 416 stainless steels are also relatively affordable options, especially for applications requiring high strength but not necessarily superior corrosion resistance.

When selecting the cheapest stainless steel for machining, it's important to consider not just the upfront cost of the material but also its machinability, tooling costs, and suitability for the intended application.

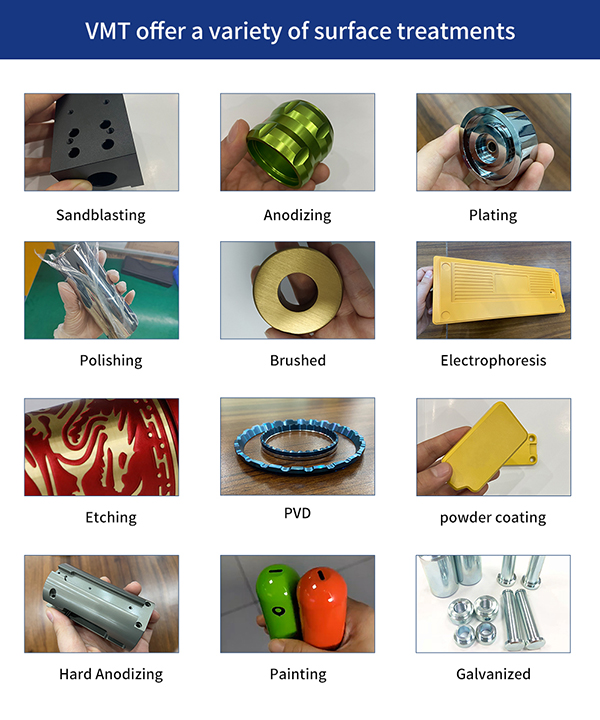

Achieving a high-quality finish is an essential part of CNC machining stainless steel. Some common surface finishing techniques include:

Due to its excellent properties, stainless steel is used in a wide variety of CNC machining applications, such as:

When it comes to CNC machining stainless steel, having the right tools and equipment is crucial for achieving precision, efficiency, and quality. Stainless steel's hardness and resistance to wear require advanced machinery, high-quality cutting tools, and specialized techniques to ensure smooth machining and maintain tool life. Below, we’ll explore the essential tools and equipment needed to tackle CNC machining stainless steel parts effectively.

CNC Machines

CNC (Computer Numerical Control) machines are the backbone of the machining process. These machines allow for highly precise, automated manufacturing of stainless steel parts with complex geometries. The most commonly used CNC machines in stainless steel machining are CNC mills, lathes, and multi-axis machines.

Choosing the right CNC machine is essential, as the machine’s rigidity, speed, and accuracy directly affect the quality of the finished part and tool wear during machining.

Cutting Tools

Cutting tools are one of the most crucial elements in CNC machining stainless steel. Stainless steel is tough to cut, and using the right tool materials and coatings can significantly improve the machining process.

The right cutting tool material and coating ensure better precision, higher surface finish quality, and extended tool life, all of which are important when machining stainless steel components.

Coolant Systems

Coolant systems are essential to manage the heat generated during the machining of stainless steel. High temperatures can damage tools, workpieces, and even affect the final product’s quality. A good coolant system keeps temperatures under control and ensures better machining efficiency.

Proper coolant selection and management reduce tool wear, minimize workpiece deformation, and improve surface finishes.

Tool Holders and Tool Accessories

Tool holders securely fasten the cutting tools to the CNC machine, ensuring stable operation and precision during machining. Tool accessories like collets, chuck jaws, and quick-change systems allow for efficient tool swapping and maintenance.

Proper tool holders and accessories improve accuracy, reduce tool vibrations, and contribute to higher-quality machined parts.

Workholding

Workholding devices securely position the stainless steel workpiece on the CNC machine during machining. The right workholding solutions ensure that the part stays firmly in place, preventing movement that could affect machining accuracy.

Effective workholding ensures that the stainless steel part is machined with the highest precision and without any risk of shifting or damage.

Measuring Tools

Precision measurements are key to ensuring that CNC-machined stainless steel parts meet the required tolerances. Using the right measuring tools allows for accurate inspection and verification of the part during and after machining.

Using high-quality measuring tools ensures that the final stainless steel parts conform to specifications and meet the required tolerances.

Safety Equipment

Safety is a top priority in CNC machining, especially when working with hard materials like stainless steel. Operators must use appropriate safety equipment to protect themselves from sharp tools, flying debris, and high-speed machinery.

Ensuring operator safety is critical to maintaining a productive and safe work environment.

CNC Programming Software

CNC programming software is used to create the code that drives CNC machines. This software is responsible for determining the tool paths, cutting speeds, and machining operations, ensuring precision and efficiency in the manufacturing process.

Advanced CNC programming software makes complex machining tasks more manageable, reducing errors and improving overall machining efficiency.

At VMT, we provide comprehensive CNC machining services for stainless steel parts. From prototyping to production, we use advanced machinery, the latest software, and industry-standard techniques to produce high-quality stainless steel components. Our team of experts can help you choose the right grade of stainless steel, select optimal cutting tools, and develop a customized machining strategy for your project. With our precision machining capabilities, we guarantee top-quality parts with tight tolerances and fast turnaround times. Start your stainless steel part CNC machining project with VMT today, and let us bring your designs to life with unmatched accuracy and efficiency.

CNC machining stainless steel presents a unique set of challenges but also offers many advantages. By understanding the properties of the material, choosing the right tools, and applying the right techniques, manufacturers can successfully overcome these challenges and produce high-quality stainless steel parts. Whether you’re machining medical, automotive, or aerospace components, mastering CNC machining stainless steel is crucial to achieving precision, performance, and durability.

1. Which is easier to machine, 304 or 316 stainless steel?

304 stainless steel is generally easier to machine than 316 due to its lower nickel content, which makes it less prone to work-hardening.

2. What materials cannot be CNC machined?

Materials that are extremely hard, brittle, or have complex grain structures, such as ceramics or some superalloys, can be challenging to CNC machine.

3. How machinable is 304 stainless steel?

304 stainless steel is relatively easy to machine compared to other grades, but it can work-harden, requiring careful attention to tooling and cutting conditions.

4. Which is easier to machine, 303 or 304?

303 stainless steel is easier to machine than 304 due to its higher sulfur content, which improves machinability.

5. Is 316L easier to machine than 316?

Yes, 316L is easier to machine than 316 due to its lower carbon content, which reduces the risk of carbide precipitation during welding and improves machinability.

6. What is the most difficult stainless steel to machine?

316 stainless steel is one of the most difficult grades to machine because of its high resistance to corrosion, hardness,and work-hardening tendencies.

7. What is the best machinable stainless steel?

303 stainless steel is considered the best for machinability because of its free-machining properties and ability to resist work hardening.

8. How difficult is it to drill 304 stainless steel?

Drilling 304 stainless steel can be difficult due to its tendency to work harden. Using the correct drill bit, cutting speeds, and lubrication techniques can help ease the process.

9. Why is stainless steel so difficult to machine?

Stainless steel is difficult to machine due to its hardness, tendency to work-harden, and high heat generation, which can cause tool wear and part distortion.

10. What speed is required for milling stainless steel?

Milling speeds for stainless steel typically range between 50 to 100 meters per minute, depending on the machine, tool, and specific material grade.

11. What is the best machining grade for stainless steel?

The best machining grade depends on the application, but 303 stainless steel is often preferred for ease of machining, while 304 and 316 are selected for their excellent corrosion resistance.

12. Is stainless steel difficult to mill?

Yes, stainless steel can be difficult to mill due to its hardness and work-hardening properties. Proper tool selection, coolant use, and machining parameters are essential for success.

13. What is the most common machined stainless steel?

304 stainless steel is the most commonly machined stainless steel due to its combination of good machinability and corrosion resistance.

14. Which cutting process is best for stainless steel?

The best cutting process for stainless steel depends on the part geometry and material grade, but milling, turning, and grinding are commonly used in CNC machining.