15 years one-stop China custom CNC machining parts factory

111 |

Published by VMT at Jun 17 2024

111 |

Published by VMT at Jun 17 2024

Everything You Need to Know About Stainless Steel Machining Materials

Introduction:

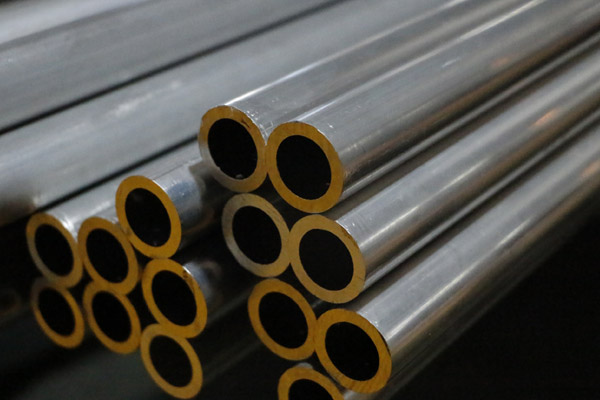

Stainless steel, as an indispensable material in modern industry, is widely acclaimed for its excellent corrosion resistance and versatile application performance. In the field of CNC machining parts manufacturing, the use of stainless steel is particularly common. This article will comprehensively introduce the basic knowledge, characteristics, advantages and disadvantages, application scenarios, as well as precautions in the use and processing of stainless steel materials, helping readers to gain a deeper understanding of stainless steel machining materials.

I. Basic Knowledge of Stainless Steel:

Stainless steel, as the name implies, is a type of steel that is not easily rusted. Its main characteristic is the high content of chromium (usually at least 10.5%), which gives stainless steel good corrosion resistance in weak corrosive media such as air, water, and steam. Stainless steel is classified into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, duplex stainless steel, etc., based on its metallographic structure. These different types of stainless steel are suitable for different application scenarios due to their unique chemical compositions and physical properties.

II. Characteristics of Stainless Steel:

Corrosion resistance: The corrosion resistance of stainless steel is one of its most significant characteristics. It can resist corrosion from various chemicals, including acids, alkalis, salts, etc.

High strength: Stainless steel has high strength and hardness, suitable for manufacturing parts and equipment that bear heavy loads.

Aesthetic appeal: Stainless steel has a metallic luster and an appealing appearance, suitable for manufacturing decorative items and products with high aesthetic requirements.

Good machinability: Stainless steel has good plasticity and weldability, making it easy to process into various shapes and specifications of parts.

III. Advantages and Disadvantages of Stainless Steel:

Advantages:

Strong corrosion resistance: Able to resist corrosion from various chemicals, prolonging service life.

High strength: Possesses high strength and hardness, suitable for heavy-duty environments.

Good aesthetic appeal: Visually pleasing appearance suitable for decoration and products with high aesthetic requirements.

Good machinability: Easy to process into various shapes and specifications of parts.

Disadvantages:

Higher cost: Stainless steel is relatively more expensive compared to other metal materials.

Poor thermal conductivity: Stainless steel has poor thermal conductivity, which may reduce thermal conduction efficiency.

Magnetism: Some stainless steel grades are magnetic, which may affect their application in specific fields.

IV. Primary Reasons for Using Stainless Steel:

The primary reasons for using stainless steel are its excellent corrosion resistance and versatile application performance. Stainless steel can resist corrosion from various chemicals, making it widely used in industries such as chemical, marine, aerospace, energy, pharmaceuticals, and food. Additionally, the high strength, good aesthetic appeal, and good machinability of stainless steel make it an ideal material for manufacturing various parts and equipment.

V. Most Common Stainless Steel Material Grades:

Stainless steel comes in various grades, with the most common ones including 304 stainless steel, 316 stainless steel, 430 stainless steel, etc. These different grades of stainless steel are suitable for different application scenarios due to their unique chemical compositions and physical properties. For example, 304 stainless steel has good corrosion resistance and machinability, suitable for manufacturing kitchenware, chemical equipment, medical devices, etc.; whereas 316 stainless steel has better corrosion resistance, suitable for marine environments and chemical equipment in highly corrosive environments.

VI. Which Stainless Steel is Best for High Temperature Resistance?

For applications requiring high temperature resistance, 310 stainless steel and 316 stainless steel are good choices. Among them, 310 stainless steel has good high-temperature oxidation resistance and can be used in the manufacturing of high-temperature machinery and heat exchangers; while 316 stainless steel can maintain good corrosion resistance in high-temperature oxidizing environments and is suitable for high-temperature production equipment, petrochemicals, etc.

VII. Common Applications of Stainless Steel:

Stainless steel has a wide range of applications, including but not limited to:

Chemical equipment: Widely used in chemical equipment due to its excellent corrosion resistance.

Architectural decoration: Ideal choice for architectural decoration materials due to its aesthetic appeal and corrosion resistance.

Medical devices: Important material for manufacturing medical instruments, medical devices, and implants due to its corrosion resistance and biocompatibility.

Tableware and kitchenware: Ideal material for tableware, kitchenware, and food processing equipment due to its corrosion resistance and ease of cleaning.

VIII. Which Industry Uses Stainless Steel the Most?

Due to its excellent corrosion resistance and versatile application performance, stainless steel is widely used in multiple industries. Among them, chemical, construction, medical, and catering industries are the fields where stainless steel is most commonly used. These industries have high requirements for the corrosion resistance, strength, aesthetic appeal, and machinability of materials, all of which stainless steel meets.

IX. Which Stainless Steel Material Grade is the Best?

The question of "which stainless steel material grade is the best" does not have a fixed answer. Different stainless steel grades have different chemical compositions and physical properties, suitable for different application scenarios. When selecting stainless steel materials, it is necessary to evaluate their performance based on specific usage environments and requirements, and choose the most suitable material accordingly.

X. Which is Better: 304 or 316 Stainless Steel?

Both 304 and 316 stainless steel are common stainless steel grades, each with its own advantages and disadvantages. 304 stainless steel has good corrosion resistance and machinability, suitable for general application scenarios; whereas 316 stainless steel has better corrosion resistance, suitable for highly corrosive environments. Therefore, when selecting stainless steel materials, it is necessary to evaluate their performance based on specific usage environments and requirements, and choose the most suitable material accordingly.

XI. What is the Most Common Corrosion in Stainless Steel?

Although stainless steel has excellent corrosion resistance, it may still corrode under certain specific environments. The most common types of corrosion include pitting corrosion, intergranular corrosion, stress corrosion cracking, etc. These types of corrosion are usually related to factors such as the chemical composition of stainless steel, the usage environment, and the processing methods.

XII. Does Stainless Steel Rust?

Although stainless steel is named for its resistance to rust, it is still possible to rust under certain conditions. This is mainly because the corrosion resistance of stainless steel is not absolute, but is affected by various factors such as its chemical composition, usage environment, and conditions. For example, in environments containing a large amount of chloride ions, such as seawater or swimming pool water, the corrosion resistance of stainless steel may be severely affected, leading to rust. Additionally, stainless steel is prone to rusting at damaged areas (such as scratches, impacts, etc.).

XIII. How to Clean Stainless Steel?

To maintain the aesthetic appeal and corrosion resistance of stainless steel, regular cleaning is necessary. When cleaning stainless steel, mild detergents and soft cloths or sponges should be used for wiping, avoiding the use of detergents containing chlorine or abrasives to prevent damage to the stainless steel surface. For stubborn stains or rust spots, specialized stainless steel cleaners or white vinegar can be used for cleaning. After cleaning, rinse with clean water and dry with a dry cloth to avoid water spots.

XIV. Is Stainless Steel 100% Stainless?

Stainless steel is not 100% rust-proof. In fact, the corrosion resistance of stainless steel is achieved through its unique chemical composition and microstructure, rather than being absolutely "stainless." The corrosion resistance of stainlesssteel may vary under different usage environments and conditions. Therefore, when using stainless steel, it is necessary to understand its performance characteristics and limitations, and take appropriate protective measures to extend its service life.

XV. How Durable is Stainless Steel?

Stainless steel has relatively high durability, primarily due to its excellent corrosion resistance and strength. Under normal usage and maintenance conditions, stainless steel products can maintain a long service life. However, it is important to note that the durability of stainless steel is not absolute, and its performance may be affected by various factors such as usage environment, conditions, and the quality of the material itself. Therefore, when selecting and using stainless steel, it is necessary to consider its performance characteristics and usage requirements comprehensively.

XVI. What is the Most Important Element in Stainless Steel?

The most important element in stainless steel is chromium (Cr). Chromium is the basic element that imparts corrosion resistance to stainless steel. When the chromium content reaches around 12%, chromium reacts with oxygen in the corrosive medium to form a thin oxide film (passivation film) on the steel surface, which can prevent further corrosion of the steel substrate. In addition to chromium, elements such as nickel (Ni) and molybdenum (Mo) also have a significant impact on the performance of stainless steel. For example, nickel can enhance the corrosion resistance and toughness of stainless steel, while molybdenum can improve its resistance to pitting and crevice corrosion.

XVII. Where is Stainless Steel Most Commonly Used?

Due to its excellent corrosion resistance and versatile application performance, stainless steel is widely used in various fields. In the construction industry, stainless steel is used to manufacture doors, windows, curtain walls, railings, etc. In the chemical industry, stainless steel is used to manufacture reactors, storage tanks, pipelines, and other equipment. In the medical field, stainless steel is used to manufacture surgical instruments, medical devices, implants, etc. In the catering industry, stainless steel is used to manufacture tableware, kitchenware, and food processing equipment. Additionally, stainless steel plays an important role in industries such as energy, transportation, aerospace, etc.

XVIII. What Causes Scratching of Stainless Steel?

The main reasons for scratching of stainless steel are as follows: improper use, such as scratching the stainless steel surface with sharp objects; mechanical damage during processing, such as scratches produced during cutting, grinding, etc.; improper cleaning, such as scratching caused by using abrasive cleaners or cleaning tools on the stainless steel surface. To reduce scratching of stainless steel, it is necessary to use and maintain stainless steel products correctly and take appropriate protective measures.

Conclusion:

Stainless steel, as an excellent metal material, has a wide range of applications in the field of CNC machining parts manufacturing. By understanding the basic knowledge, characteristics, advantages and disadvantages, application scenarios, as well as precautions in the use and processing of stainless steel materials, we can better select and use stainless steel materials to meet various machining requirements. Meanwhile, with the continuous advancement of technology and innovation, the performance and application fields of stainless steel will be further expanded and improved.

FAQs:

What are the advantages of stainless steel CNC machining parts?

Stainless steel CNC machining parts have advantages such as strong corrosion resistance, high strength, good aesthetic appeal, etc., suitable for various application scenarios. Through CNC machining technology, high-precision and efficient processing can be achieved, meeting customers' personalized requirements.

How to customize stainless steel CNC machining parts?

To customize stainless steel CNC machining parts, it is necessary to collaborate with CNC machining factories, providing detailed part drawings and processing requirements. The CNC machining factory will perform precise machining and manufacturing based on the drawings and requirements to meet customer needs.

What role does CNC prototype machining play in stainless steel processing?

CNC prototype machining is a high-precision and efficient machining method that can quickly produce prototypes or samples of stainless steel materials. This is crucial during the product design and development stage, as it helps customers quickly verify the feasibility and performance of the product.

How to choose a suitable CNC machining service provider?

Choosing a suitable CNC machining service provider requires considering their machining capabilities, equipment level, technical strength, service quality, etc. Customers can evaluate their comprehensive strength and credibility by checking the supplier's qualifications, on-site visits, consulting other customers, etc.

The above is a comprehensive introduction to stainless steel machining materials, hoping to be helpful to readers. If you have more questions or need further understanding, please feel free to consult relevant professionals.