15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

153 |

Published by VMT at May 07 2024

153 |

Published by VMT at May 07 2024

Commonly Used Materials in the Medical Industry

In the medical field, commonly used materials include medical polymers, medical metals, medical ceramics, and biocompatible materials. These materials play crucial roles in the manufacturing of medical instruments and devices due to their unique properties and advantages.

Medical Polymers

Medical polymers are widely used in the medical field due to their excellent biocompatibility, corrosion resistance, and ease of processing. Materials such as polyethylene and polypropylene are commonly used in the manufacturing of medical devices such as infusion bottles, syringes, and catheters. Meanwhile, elastomeric materials like polyurethane and silicone rubber are extensively utilized in high-end medical products such as artificial blood vessels, artificial joints, and artificial heart valve.

Medical Metals

Medical metals possess excellent mechanical properties and corrosion resistance, making them indispensable in medical device manufacturing. Stainless steel, titanium alloys, and other metal materials are commonly used in the production of surgical instruments, dental implants, orthopedic implants, etc. Additionally, the development of biocompatible metal materials has led to their increased application in internal medical devices like pacemakers and vascular stents.

Medical Ceramics

Medical ceramics exhibit outstanding biocompatibility, wear resistance, and chemical stability, making them suitable for manufacturing dental implants, artificial joints, bone screws, and more. Moreover, bioactive ceramic materials can form chemical bonds with human tissues, promoting tissue regeneration and repair.

Biocompatible Materials

Biocompatible materials refer to materials that do not elicit adverse biological reactions when in contact with human tissues. Biodegradable polymers like polylactic acid and polyglycolic acid gradually degrade and are absorbed by the body, reducing the long-term impact of implants on the body. These materials find widespread applications in surgical sutures, drug delivery systems, etc.

Advantages of Materials Used in the Medical Industry

High Safety

Materials used in the medical industry must exhibit excellent biocompatibility to ensure they do not cause adverse reactions when introduced into the human body. These materials undergo rigorous biocompatibility and toxicity tests to ensure patient safety and health.

Good Stability

Medical instruments and devices require long-term stability and reliability to ensure consistent performance throughout their usage. Medical materials typically possess excellent corrosion resistance, wear resistance, and fatigue resistance to meet the stability requirements of medical devices.

Ease of Processing

Computer Numerical Control (CNC) machining technology plays a vital role in modern medical device manufacturing. Medical materials usually have good machinability, allowing them to adapt to various CNC machining requirements and achieve high-precision, efficient part manufacturing.

Versatility

As medical technology advances, the functional requirements of medical instruments and devices become increasingly diverse. Medical materials can achieve functional diversification through modification, compounding, etc., meeting the needs of medical devices in drug release, tissue repair, biological monitoring, and other aspects.

Applications and Advantages of CNC Machined Parts in the Medical Industry

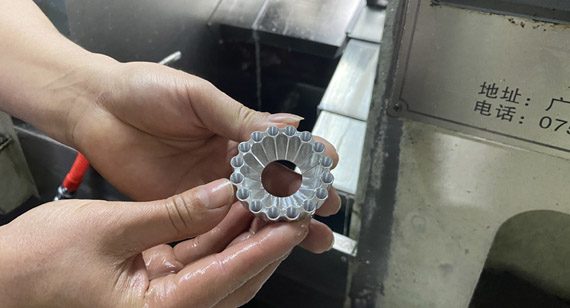

CNC machining technology plays a crucial role in medical device manufacturing. Through CNC machining, parts with complex shapes and high precision can be accurately manufactured, catering to a wide range of applications in the medical industry, such as surgical instruments, artificial joints, dental implants, etc.

The advantages of CNC machined parts mainly include:

High Precision: CNC machining technology can achieve high-precision part manufacturing, ensuring the performance and safety of medical devices.

High Efficiency: CNC machining features high efficiency, enabling rapid completion of large-scale part manufacturing tasks, meeting the demands of medical device manufacturing.

Flexibility: CNC machining technology can adapt to the manufacturing of various complex-shaped parts, providing more possibilities for the design of medical devices.

Traceability: Data recording and analysis during CNC machining processes contribute to the traceability of part manufacturing, enhancing the quality control level of medical devices.

The Role of CNC Machining Factories in the Medical Industry

As vital bases for medical device manufacturing, CNC machining factories possess advanced CNC machining equipment and professional technical teams, capable of providing high-quality CNC machined parts and services for the medical industry. By continuously optimizing production processes and improving technical capabilities, CNC machining factories can meet the strict requirements of the medical industry for medical device performance and quality, driving the continuous advancement of medical technology.

In conclusion, materials such as medical polymers, medical metals, medical ceramics, and biocompatible materials offer extensive advantages and application prospects in the medical industry. CNC machining technology and CNC machining factories play critical roles in medical device manufacturing, providing high-precision, high-efficiency, and high-quality parts and services for the medical industry. With the continuous development of medical technology, we believe that more innovative materials and CNC machining technologies will be applied to the medical industry, making greater contributions to human health.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!