15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

151 |

Published by VMT at May 06 2024

151 |

Published by VMT at May 06 2024

In the field of CNC machining, aluminum CNC machined parts are widely used in various industries such as aerospace, automotive manufacturing, and electronics due to their lightweight, corrosion resistance, and excellent conductivity and thermal properties. However, aluminum alloy materials have relatively low hardness and are prone to wear, which limits their application to some extent. Therefore, increasing the surface hardness of aluminum CNC machined parts to enhance their wear resistance and service life has become a common concern for CNC machining factories and researchers. This article will detail several effective methods for increasing the surface hardness of aluminum CNC machined parts, aiming to provide valuable references for professionals in the CNC machining field.

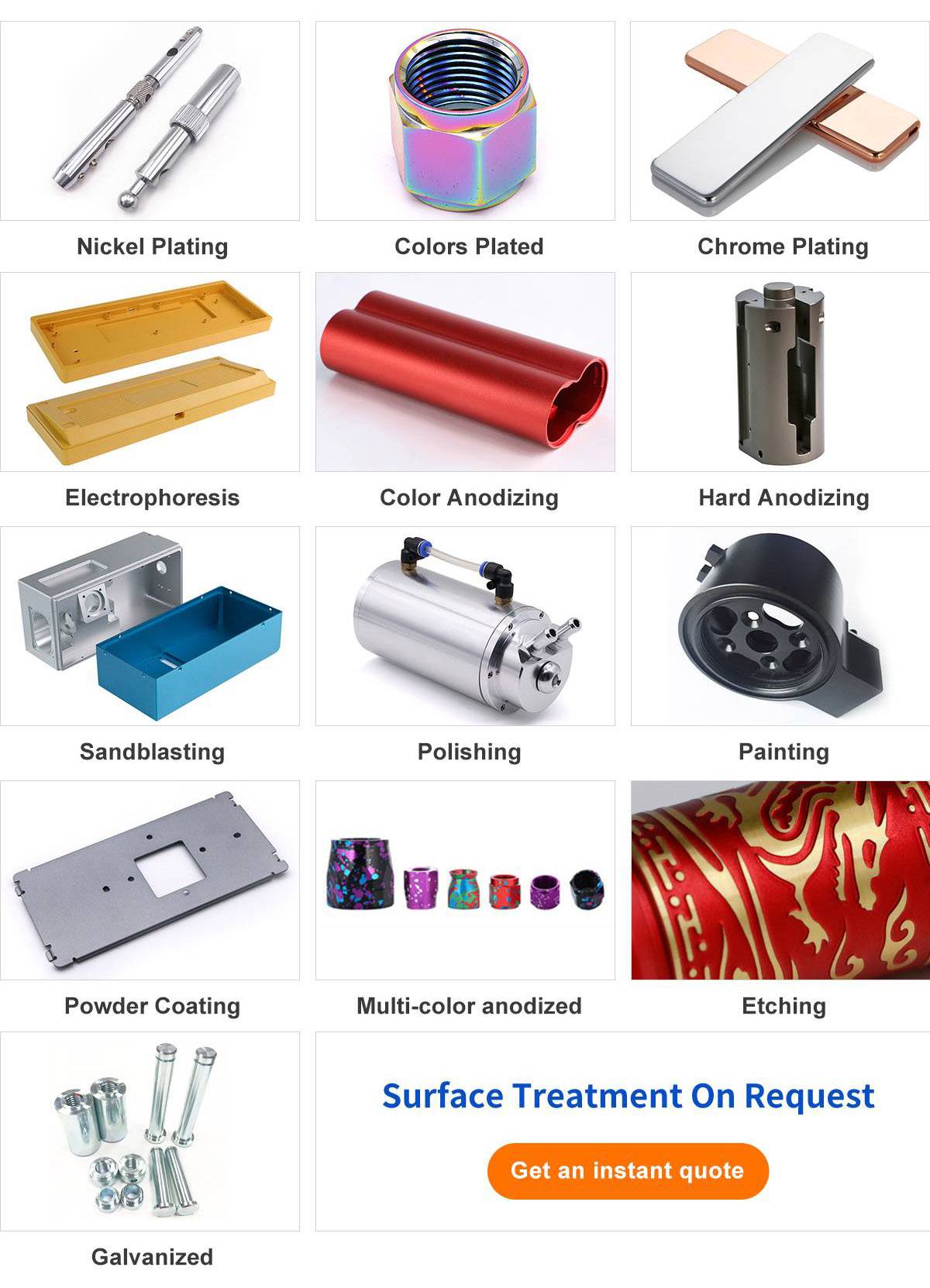

I. Surface Finishing Techniques

Surface hardening is a technique that directly affects the surface of parts, aiming to improve hardness by altering their physical and chemical properties.

Quenching Hardening

Quenching involves rapidly cooling the aluminum parts after heating them to a certain temperature, refining the grains of the aluminum alloy to increase surface hardness. Quenching hardening is suitable for aluminum CNC machined parts with high hardness requirements. However, it's important to note that quenching may induce stress and deformation, so proper tempering is necessary after quenching to relieve residual stresses.

Aging Hardening

Aging hardening involves subjecting aluminum parts to natural aging for a certain period and then controlling the aging temperature and time to form stable compounds between alloying elements and the matrix, thereby increasing surface hardness. Aging hardening is characterized by its simple process and relatively low cost, making it suitable for applications with moderate hardness requirements.

II. Anodizing Treatment

Anodizing is a technique that forms an oxide film on the surface of aluminum parts through electrolysis. The oxide film exhibits high hardness, good wear resistance, and strong corrosion resistance, effectively increasing the surface hardness of aluminum CNC machined parts. During the anodizing process, the aluminum parts serve as the anode and form a dense layer of aluminum oxide film on the surface under the action of the electrolyte. By controlling the electrolysis time and voltage, the thickness and properties of the oxide film can be adjusted to meet different requirements.

Anodizing treatment offers mature technology, simple operation, and environmental friendliness, making it widely used in surface treatment of aluminum CNC machined parts. However, it's important to note that the surface color of parts may change after anodizing, and the oxide film may be vulnerable to damage in specific environments, so selection should be based on specific application scenarios.

III. Laser Cladding Technology

Laser cladding is a technique that utilizes a high-energy laser beam to melt the coating material and fuse it with the substrate material. By selecting suitable coating materials and cladding process parameters, a high-hardness and wear-resistant cladding layer can be formed on the surface of aluminum CNC machined parts, significantly increasing surface hardness.

Laser cladding technology offers advantages such as tight bonding between the cladding layer and the substrate, excellent coating performance, and high machining accuracy, making it particularly suitable for aluminum CNC machined parts with extremely high surface performance requirements. However, this technology requires high equipment costs and has a high level of operational complexity, usually requiring professional CNC machining factories for implementation.

IV. Surface Coating Technology

In addition to the above methods, a high-hardness coating material, such as silicon carbide or silicon nitride ceramics, can be applied to the surface of aluminum CNC machined parts through spraying or electroplating to form a layer of metal or non-metal coating. These coating materials have high hardness and wear resistance, effectively increasing the surface hardness of aluminum CNC machined parts. However, it's crucial to ensure strong adhesion between the coating and the substrate, as well as control the uniformity and thickness of the coating.

V. Comprehensive Application in CNC Machining Services

In CNC machining services, increasing the surface hardness of aluminum CNC machined parts typically involves a combination of multiple techniques based on the specific application requirements and material characteristics of the parts. For example, improving the base hardness of parts through quenching or aging hardening processes, followed by further enhancement of surface performance through anodizing or laser cladding techniques. Additionally, CNC machining factories should focus on close collaboration with material suppliers, coating manufacturers, and other upstream and downstream enterprises to jointly develop new surface treatment technologies and materials to meet the evolving market demands.

In conclusion, there are various methods to increase the surface hardness of aluminum CNC machined parts, each with its own advantages and limitations. CNC machining factories should choose appropriate treatment methods based on practical considerations to improve the wear resistance and service life of parts. Moreover, with the continuous advancement of technology and the emergence of new materials, it is believed that more efficient and environmentally friendly surface hardening technologies will be applied in the field of aluminum CNC machining in the future.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!