15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

120 |

Published by VMT at Feb 23 2024

120 |

Published by VMT at Feb 23 2024

Introduction:

In the realm of CNC machined parts manufacturing, the adhesion of surface coatings stands as a crucial benchmark for part quality. Coating adhesion not only influences the part's appearance but also plays a pivotal role in its performance and lifespan. Therefore, ensuring the adhesion of surface coatings on CNC machined parts is of paramount importance. This article delves into the key factors affecting coating adhesion and outlines methods to enhance adhesion in practical production.

I. Factors Influencing Coating Adhesion on CNC Machined Parts:

Substrate Surface Treatment:

The cleanliness and roughness of the substrate surface significantly impact coating adhesion. The presence of impurities such as surface contaminants, grease, and moisture weakens the bonding between the coating and the substrate. Thorough cleaning and pre-treatment of the substrate surface before coating are essential.

Coating Process Selection:

The choice of coating process has a crucial influence on coating adhesion. Different coating processes (e.g., spraying, dipping, brushing) have varying effects on adhesion. Additionally, factors such as temperature, humidity, and coating technique during the process can affect coating adhesion.

Coating Material:

The properties and performance of coating materials directly affect adhesion. Parameters such as wetting ability, viscosity, and curing temperature of different materials play a vital role in coating adhesion. Selecting appropriate coating materials is a key factor in ensuring adhesion.

Curing Conditions:

The curing conditions of the coating significantly impact adhesion. Factors such as temperature, curing time, and heating methods influence the bonding between the coating and the substrate. Ensuring coating is applied under recommended curing conditions is necessary.

Environmental Factors:

Environmental factors such as temperature, humidity, and air cleanliness also affect coating adhesion. In high humidity or polluted environments, coatings are prone to defects and a decrease in adhesion.

II. Methods to Improve Coating Adhesion on CNC Machined Parts:

Optimize Substrate Surface Treatment Process:

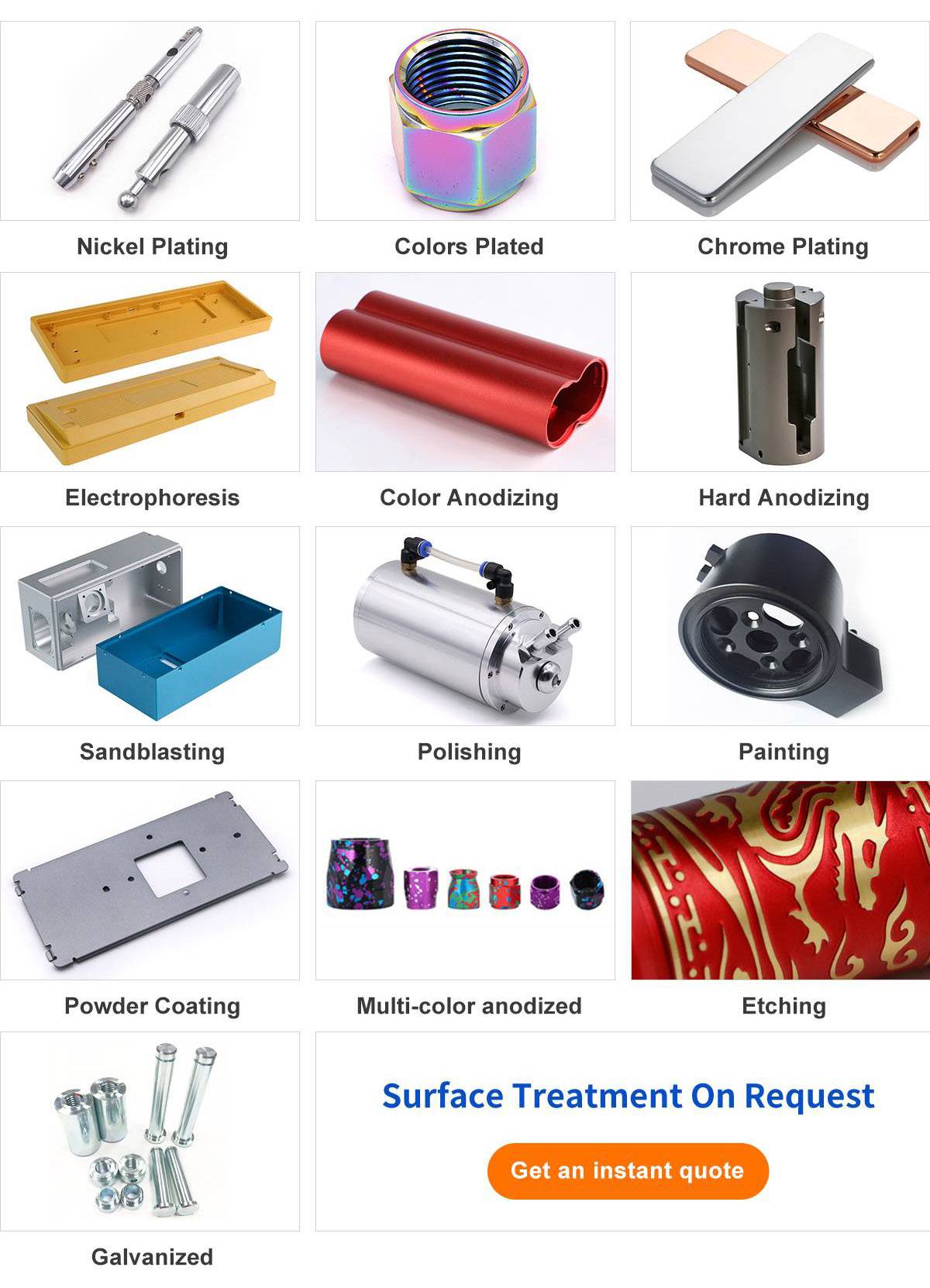

Optimal substrate surface treatment is foundational to improving coating adhesion. Employing methods such as sandblasting, mechanical, or chemical treatment to enhance surface roughness aids in increasing coating adhesion. Simultaneously, ensuring substrate surface cleanliness by removing oil, moisture, and other impurities is crucial.

Select Appropriate Coating Process and Materials:

Choose the right coating process (e.g., electrostatic spraying, thermal spraying) and materials based on part geometry and coating requirements. For challenging areas, alternative processes like dipping or roll coating can be considered. Use coating systems with excellent adhesion properties.

Control Coating Environment:

Maintain cleanliness and stable humidity in the coating environment to enhance coating adhesion. Establish a strict air filtration and purification system, control temperature and humidity within suitable ranges, and reduce the impact of environmental factors on coating quality.

Standardize Operational Procedures:

Develop and enforce rigorous coating operation procedures, ensuring each step follows standard operating protocols. Regularly train operators in correct coating techniques and precautions to minimize human-related influences on coating adhesion.

Testing and Quality Assurance:

Conduct regular adhesion tests to ensure compliance with quality standards. Utilize methods such as cross-cut tests, bend tests, etc., to evaluate coating adhesion. Address non-compliant parts through rework or disposal to prevent defective parts from progressing to subsequent processes or reaching customers.

Equipment Maintenance and Upgrades:

Regularly maintain coating equipment to ensure its optimal condition. Upgrade or replace outdated or underperforming equipment to improve production efficiency and coating quality.

Continuous Improvement and Innovation:

Stay abreast of industry trends and technological advancements. Introduce advanced coating materials and processes to elevate the level of coating adhesion on CNC machined parts. Foster collaboration with suppliers and customers, providing timely feedback on quality information for mutual improvement.

III. Case Analysis and Practical Experience:

In a case study, a mechanical manufacturing enterprise aimed to enhance coating adhesion on CNC machined parts. The company implemented a series of improvement measures: optimizing substrate surface treatment processes, selecting high-performance coating materials and processes, strengthening environmental control, standardizing operational procedures, conducting regular quality tests, and maintaining equipment. These measures significantly elevated the coating adhesion level, contributing to overall product quality and customer satisfaction.

IV. Conclusion and Outlook:

Ensuring coating adhesion on CNC machined parts is a systemic effort, considering various factors such as processes, materials, equipment, and environment. By comprehensively addressing these aspects and adopting effective measures, companies can significantly improve coating adhesion. As technology evolves, and new materials and processes emerge, the technical level of coating adhesion on CNC machined parts is expected to advance further.

To adapt to this trend, companies should remain vigilant to innovations in coating technology, promptly adopting advanced materials and processes. Additionally, emphasis on professional talent development and technical team building is crucial to elevate employee expertise and technological capabilities, providing robust support for sustained business development.

In conclusion, ensuring coating adhesion on CNC machined parts is a multifaceted task that requires a holistic approach. Companies should take practical and effective measures, continuously improving coating adhesion levels to meet market demands and customer expectations. In a fiercely competitive market environment, only by consistently enhancing product quality and technological proficiency can companies maintain a competitive edge.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!