15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

500 |

Published by VMT at Feb 19 2024

500 |

Published by VMT at Feb 19 2024

Introduction:

In the manufacturing industry, CNC machined parts are widely utilized for their advantages in high precision and complex structures across various fields. However, due to the diversity of working environments and usage conditions, the surfaces of CNC machined parts are susceptible to rust and corrosion. This not only impacts the product's appearance but can also compromise its performance and lifespan. This article explores methods and strategies to avoid rust and corrosion on the surfaces of CNC machined parts, ensuring product quality and reliability.

I. Material Selection and Treatment:

Choosing materials with excellent corrosion resistance is crucial in preventing rust and corrosion. Materials like stainless steel, aluminum alloys, and specific alloys with good anti-rust and corrosion properties are preferred. Additionally, pre-treating material surfaces, such as sandblasting, acid washing, passivation, enhances their anti-rust capabilities. Consideration of material performance in specific environments and compatibility with other materials is essential during material selection.

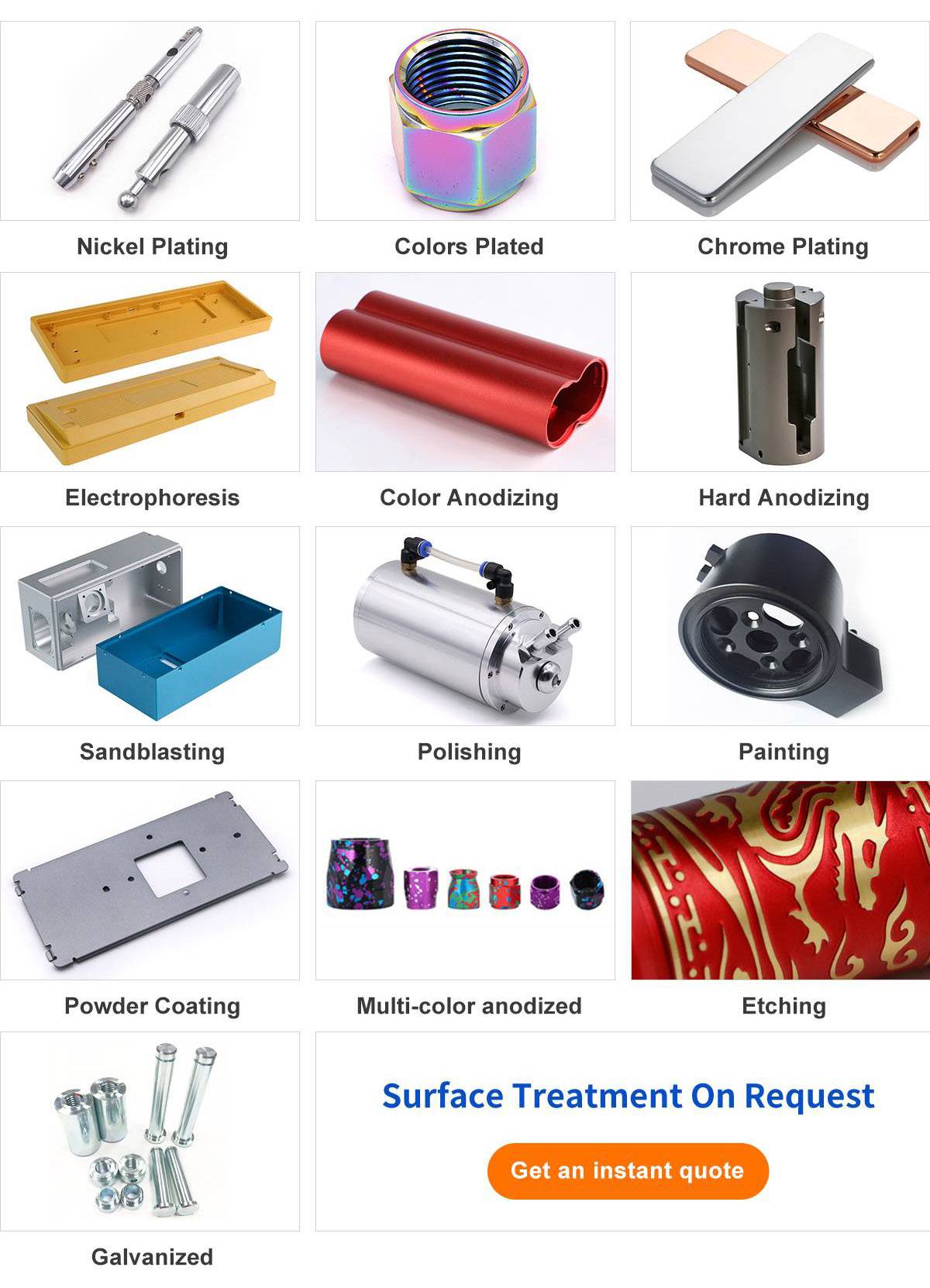

II. Surface Coating and Plating:

Applying surface coatings and plating treatments is an effective method to prevent rust and corrosion on CNC machined parts. Coating surfaces with anti-rust coatings or plating them with corrosion-resistant layers isolates the metal from the external environment, preventing corrosion. Common coating and plating materials include paint, varnish, galvanization, and chrome plating. The choice depends on specific working environments and corrosion resistance requirements.

III. Environmental Adaptability Design:

During the design phase of CNC machined parts, their durability and adaptability in specific working environments should be thoroughly considered. Optimizing structural design to reduce gaps and corners minimizes the retention and accumulation of corrosive substances on the surface. Additionally, designs should account for drainage and ventilation to reduce moisture and harmful gas accumulation.

IV. Process Control and Machining Quality:

Process control during CNC machining is crucial in preventing surface rust and corrosion. Ensuring the accuracy and stability of machining equipment reduces the impact of surface roughness on anti-rust performance. Controlling the quality and quantity of cutting fluids prevents harmful components in the cutting fluid from causing surface corrosion. Proper cleaning after machining is also vital, using suitable detergents to remove cutting fluids, oil, and other impurities.

V. Storage and Transportation Environment:

During storage and transportation, CNC machined parts may be exposed to environmental factors leading to rust and corrosion. Therefore, maintaining a dry, clean, and well-ventilated storage and transportation environment is crucial. For parts stored for extended periods, regular inspections and maintenance should be conducted to promptly identify and address potential rust and corrosion issues.

VI. Maintenance and Care:

For CNC machined parts in use, regular maintenance and care are essential in preventing rust and corrosion. Periodic cleaning, applying oil, or recoating with anti-rust coatings help maintain the surface in good condition and extend its lifespan. Additionally, strictly adhering to operating procedures during use prevents surface damage or corrosion resulting from improper usage.

VII. Continuous Improvement and Innovation:

As new materials, processes, and technologies continue to emerge, the CNC machined parts manufacturing industry should focus on continuous improvement and innovation. Companies should stay updated on industry trends and technological advancements, consistently introducing new materials, processes, and technologies to enhance product anti-rust and corrosion performance. Simultaneously, ongoing improvement of existing processes and optimization should occur, reducing costs and increasing product competitiveness. Collaboration with research institutions and universities can further drive innovation and provide robust support for corporate advancement.

VIII. Customer Communication and After-Sales Service:

For manufacturing companies, maintaining effective communication and providing excellent after-sales service are crucial. After product delivery, regular communication with customers to understand product usage and address any issues is important. For rust and corrosion issues reported by customers, prompt responses and solutions should be provided. Through high-quality after-sales service, companies can earn customer trust and build a positive reputation.

Conclusion:

Preventing rust and corrosion on CNC machined parts surfaces requires a comprehensive approach. From material selection and treatment to surface coating and plating; from environmental adaptability design to process control and machining quality; from storage and transportation environment to maintenance and care; from continuous improvement and innovation to customer communication and after-sales service. By comprehensively implementing these measures and continually optimizing and refining production processes, companies can deliver CNC machined parts with outstanding anti-rust and corrosion performance. This contributes to extending product lifespan, reducing maintenance costs, meeting customer needs, and ensuring market competitiveness, providing robust assurance for sustained growth.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!