15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

186 |

Published by VMT at Jan 25 2024

186 |

Published by VMT at Jan 25 2024

Introduction:

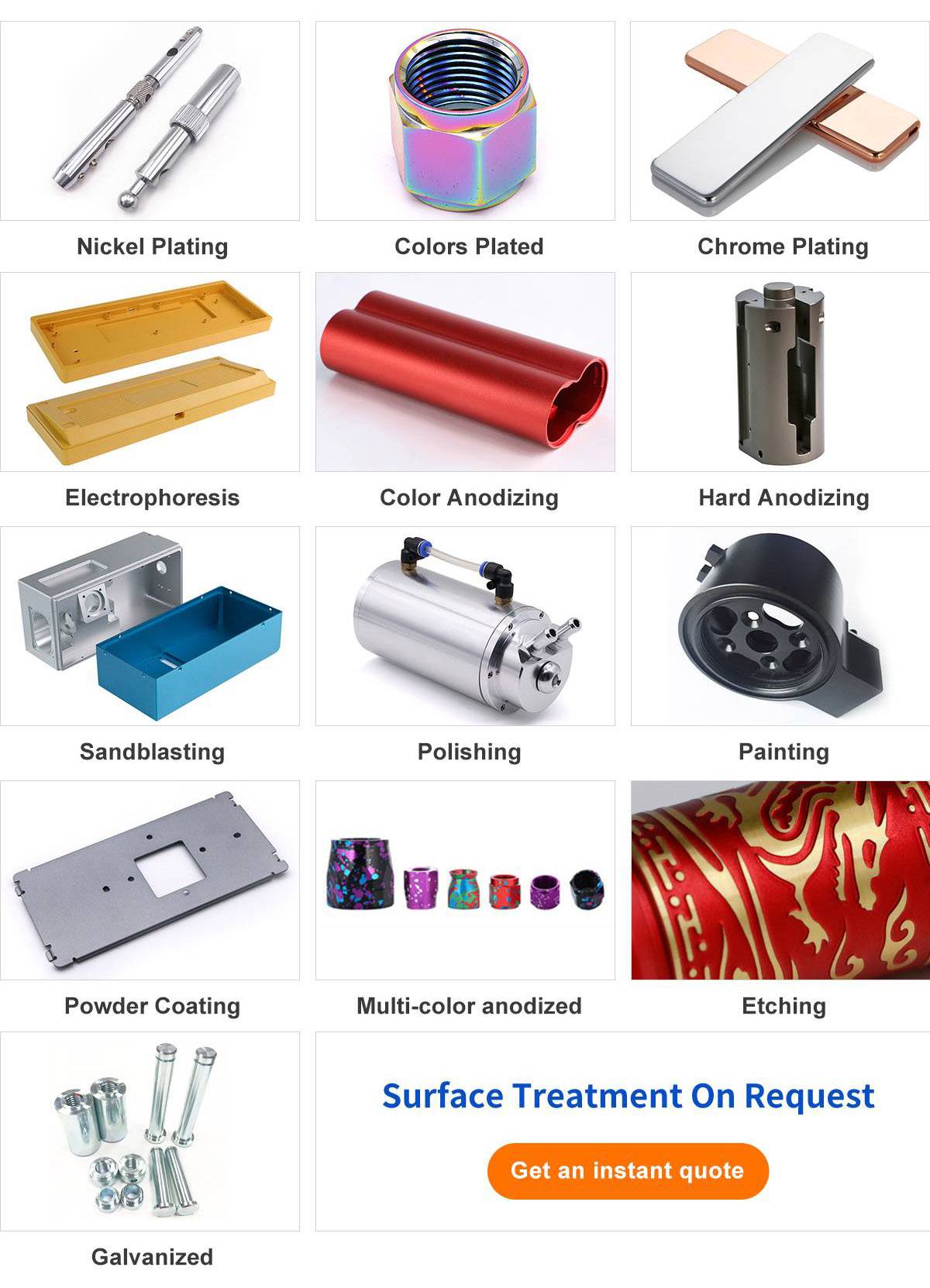

The application of CNC machined parts in the industrial sector is expanding rapidly. Surface treatment, as a crucial stage in part processing, significantly influences the performance and lifespan of these components. This article explores strategies for ensuring the consistency of surface treatment quality in CNC machined parts to guarantee product reliability and performance.

I. Choosing Appropriate Surface Treatment Methods:

Different surface treatment methods have varied effects on part performance. When selecting a surface treatment method, considerations should encompass the material of the part, its operating environment, and performance requirements. For instance, parts requiring enhanced wear resistance may undergo hard anodization, while those needing improved corrosion resistance may opt for powder coating or painting. Choosing the right surface treatment method ensures the consistency of part performance.

II. Establishing Strict Process Flows and Operating Standards:

Developing rigorous process flows and operating standards is pivotal in ensuring the consistency of surface treatment quality. Detailed process flows should outline each processing step, parameter settings, and operational requirements, specifying measures for handling exceptional situations. Operating standards should involve systematic training for employees, ensuring their proficiency in mastering process flows and operational skills. Standardized operations and management effectively reduce the impact of human factors on surface treatment quality.

III. Using High-Quality Surface Treatment Materials:

The quality of surface treatment materials directly impacts part performance. Utilizing high-quality surface treatment materials enhances part wear resistance, corrosion resistance, and aesthetics. When selecting materials, attention should be given to composition, performance indicators, and the reputation of suppliers. Simultaneously, establishing a strict material inspection system for incoming surface treatment materials ensures they meet process requirements.

IV. Strengthening Equipment Maintenance and Management:

The operational status of surface treatment equipment significantly influences the surface quality of parts. Strengthening equipment maintenance and management to ensure equipment operates optimally is foundational to achieving consistent surface treatment quality. Regular inspections, maintenance, and repairs of equipment should be conducted to identify and resolve potential issues promptly. Establishing equipment management records for recording and analyzing equipment operation and maintenance conditions facilitates timely adjustments to management strategies.

V. Implementing Comprehensive Quality Management:

Comprehensive quality management, emphasizing participation from all employees and controlling the entire process, is crucial in ensuring the consistency of surface treatment quality for CNC machined parts. By establishing a comprehensive quality management system that delineates responsibilities and workflows for each department, reinforcing quality awareness, and increasing employee emphasis on surface treatment quality, organizations can achieve a higher level of consistency. Simultaneously, enhancing the collection, analysis, and feedback of quality data allow for timely adjustments to process parameters and management measures. Through continuous improvement and enhancement, the level of consistency in surface treatment quality can be continually elevated.

VI. Establishing Strict Quality Inspection and Evaluation Systems:

Establishing a rigorous quality inspection and evaluation system is a critical aspect of ensuring the consistency of surface treatment quality for CNC machined parts. Detailed inspection standards and methods should be formulated, encompassing comprehensive inspections of part appearance, performance, and reliability. Periodic evaluations and audits of the surface treatment process should be conducted to identify potential issues and implement improvement measures promptly. Through continuous quality improvement, the stability and consistency of surface treatment quality can be continually enhanced.

Conclusion:

In conclusion, ensuring the consistency of surface treatment quality in CNC machined parts requires a multifaceted approach. Key elements include choosing appropriate surface treatment methods, establishing strict process flows and operating standards, selecting high-quality surface treatment materials, strengthening equipment maintenance and management, implementing comprehensive quality management, and establishing strict quality inspection and evaluation systems. Additionally, continuous improvement and elevation of surface treatment quality consistency are achieved through a commitment to ongoing improvement and meeting customer needs and expectations.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!