15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

117 |

Published by VMT at Feb 08 2024

117 |

Published by VMT at Feb 08 2024

As technology advances, the widespread application of aluminum CNC machined parts across various industries is becoming more apparent. The surface color and glossiness of these parts, as crucial indicators of quality, directly impact both aesthetics and functionality. This article delves into the intricacies of controlling the surface color and glossiness of aluminum CNC machined parts to ensure they meet customer expectations and requirements.

The type and condition of aluminum directly influence the surface color and glossiness. When selecting materials, prioritize high-purity aluminum with low impurity content. For instance, aerospace-grade aluminum alloys often exhibit superior surface quality. Additionally, choosing the appropriate aluminum condition, such as H111 or O state, provides a solid foundation for subsequent machining.

2. Tool Selection and Cutting Parameter Optimization

The choice of tools and optimization of cutting parameters are critical for achieving the desired surface color and glossiness in aluminum CNC machined parts. Using sharp tools reduces heat and pressure during cutting, minimizing the risk of surface heat damage and plastic deformation. Properly setting cutting parameters, including cutting speed, feed rate, and depth of cut, effectively controls temperature and cutting forces, ensuring the quality of the part's surface.

3. Cooling Methods

The use of coolant during CNC machining plays a crucial role in controlling the surface color and glossiness of aluminum parts. Employing suitable coolant and cooling methods effectively lowers the temperature in the cutting zone, reducing the risk of heat damage and oxide layer formation. This not only enhances the surface quality of the part but also extends the lifespan of cutting tools.

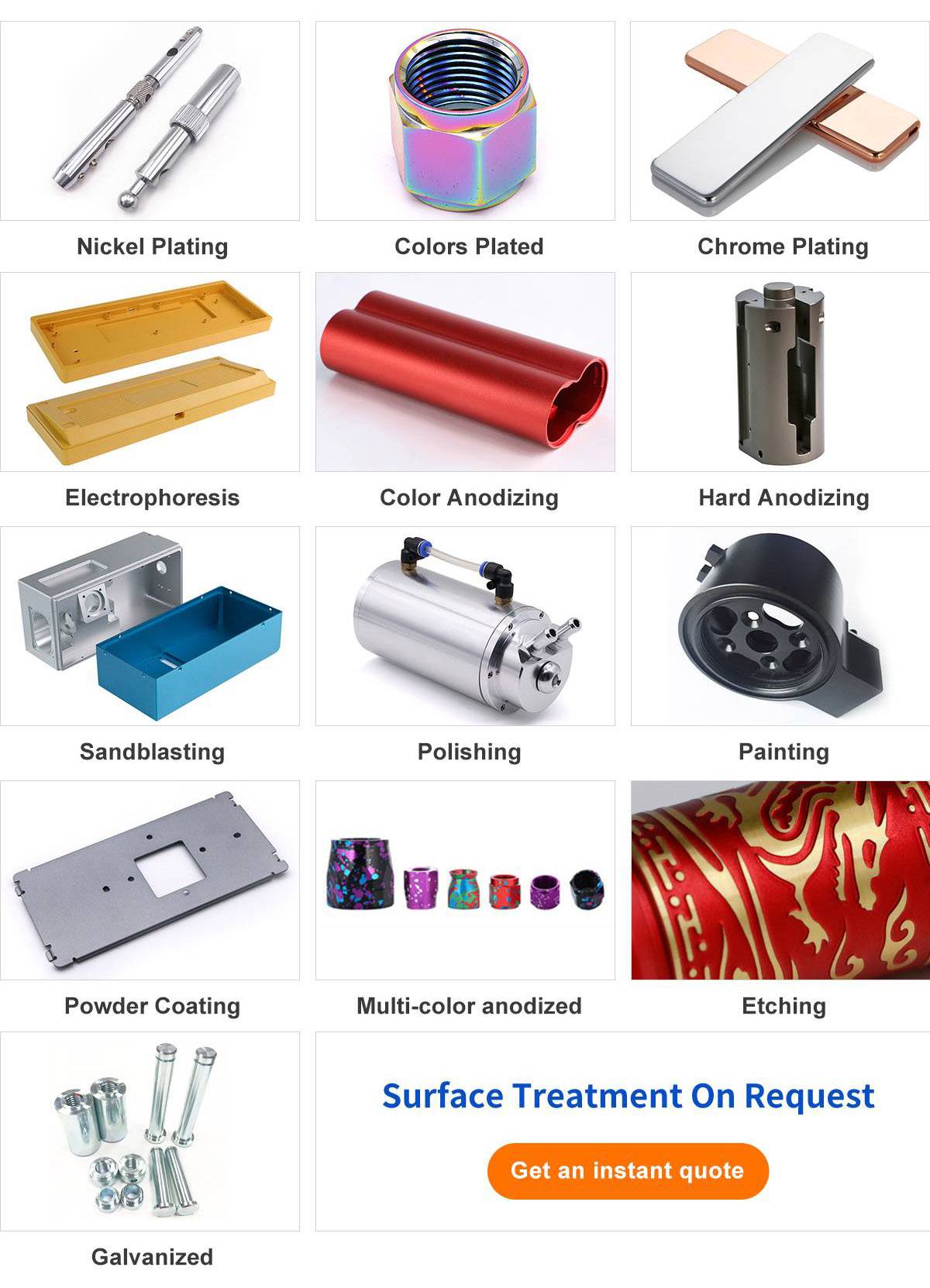

4. Polishing and Surface Treatment

Polishing is a key step in improving the surface quality of aluminum CNC machined parts. Depending on the machining requirements, choose suitable polishing methods and materials, such as mechanical polishing or chemical polishing. Additionally, for specific appearance or functional needs, surface treatments like anodizing or coating can further enhance the color and glossiness of the part.

5. Environmental Factor Control

Environmental factors such as temperature, humidity, and air cleanliness can influence the surface color and glossiness of aluminum CNC machined parts. Maintaining a consistent temperature and humidity helps minimize the impact of environmental fluctuations on the machining process. Additionally, improving the air cleanliness in the machining environment reduces dust and contaminants, preserving the quality of the part's surface.

Establishing a comprehensive quality management system ensures overall control from material selection and processes to production workflows. Conduct regular quality checks, including visual inspections and glossiness measurements, to promptly identify and address potential issues. Simultaneously, continuously collect and analyze production process data to optimize process parameters and control methods, enhancing the stability of the surface color and glossiness of aluminum CNC machined parts.

7. Employee Training and Skill Enhancement

Strengthening employee training and skill enhancement is a crucial measure to ensure the quality of the surface of aluminum CNC machined parts. Through regular training courses and sharing of practical experience, elevate employees' operational skills and sensitivity to surface quality. Emphasize the importance of quality awareness, encourage employees to identify problems in daily work, propose improvement suggestions, and actively participate in improvement activities.

Conclusion:

Controlling the surface color and glossiness of aluminum CNC machined parts is a systematic and meticulous process. From material selection, tool and cutting parameter optimization to cooling methods, polishing, surface treatment, environmental factor control, quality management, and employee training, each aspect requires strict oversight. By comprehensively considering these factors and implementing corresponding measures, the surface color and glossiness of aluminum CNC machined parts can be effectively improved, meeting customer expectations and requirements.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!