15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

160 |

Published by VMT at Mar 18 2024

160 |

Published by VMT at Mar 18 2024

Evaluating the Economic and Feasibility Aspects of Surface Treatment in CNC Machining

Introduction:

In the realm of CNC machining part manufacturing, surface treatment stands as a crucial step influencing not only the aesthetic quality of components but also their performance and lifespan. Hence, for CNC machining factories, assessing the economic and feasibility aspects of surface treatment is of paramount importance. This article delves into the rational evaluation of CNC machining surface treatment from both economic and feasibility perspectives.

I. Overview of CNC Machining Surface Treatment:

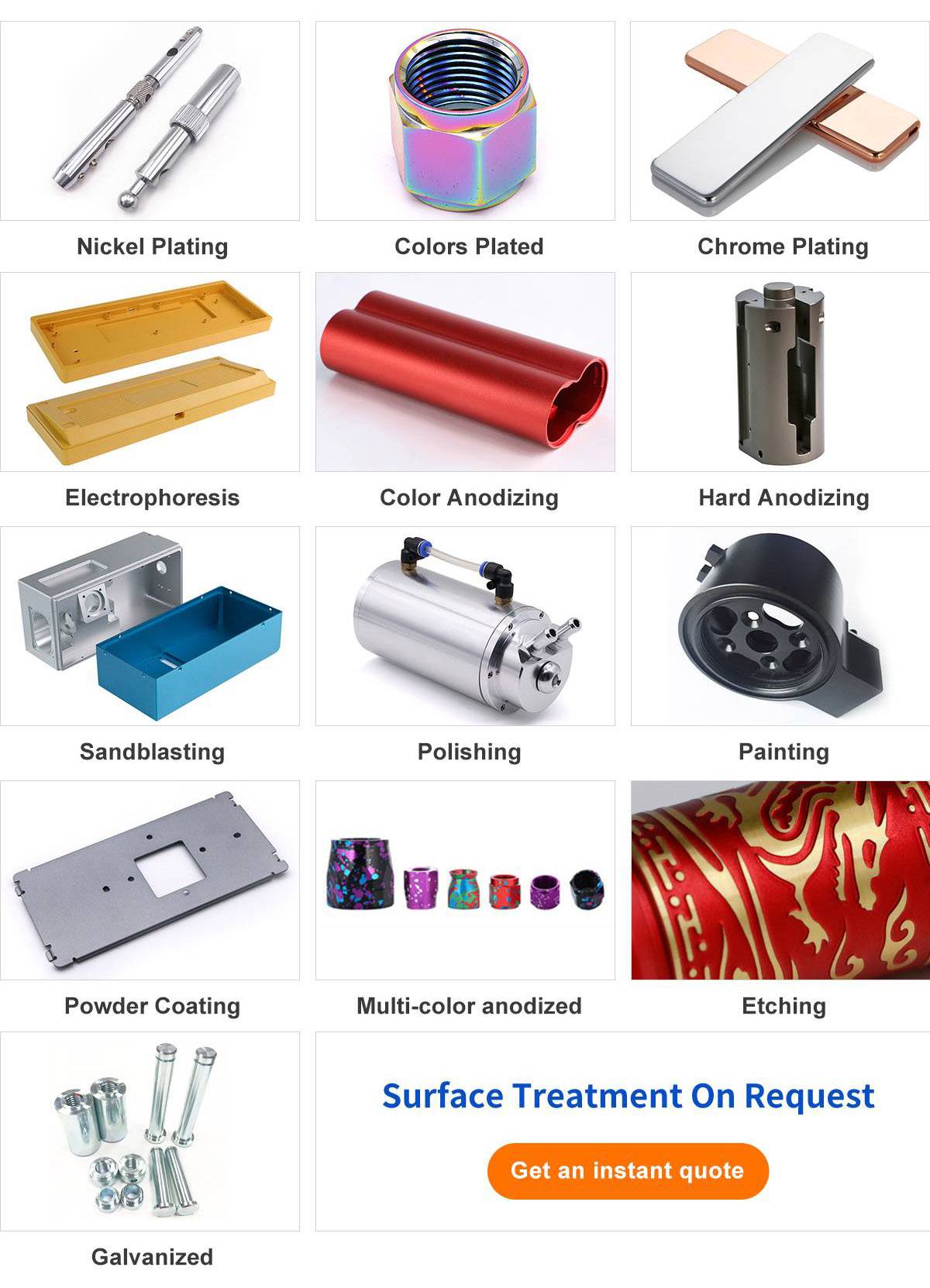

CNC machining surface treatment involves enhancing or modifying the surface of machined components through a series of physical or chemical methods. Common methods include sandblasting, polishing, electroplating, anodizing, and more. These treatments can alter surface characteristics like roughness, hardness, corrosion resistance, and conductivity to meet diverse usage requirements.

II. Assessing the Economic Aspects of CNC Machining Surface Treatment:

Cost Analysis:

Evaluating the economic aspects begins with a thorough cost analysis, encompassing considerations such as raw material costs, equipment depreciation, labor costs, and energy consumption. Different surface treatment methods exhibit significant cost disparities; for instance, sandblasting tends to be simpler and more cost-effective compared to processes like electroplating or anodizing, which require additional equipment and chemical agents.

Value Engineering Analysis:

Value engineering analysis, a method to assess cost-effectiveness, involves comparing the value of components before and after surface treatment. This comparison aids in determining whether the surface treatment is economically justified. For example, though processes like anodizing may incur higher costs, the significant improvement in corrosion resistance leading to an extended lifespan may outweigh the initial investment, proving its economic viability.

III. Evaluating the Feasibility Aspects of CNC Machining Surface Treatment:

Technical Feasibility:

Technical factors are paramount when assessing the feasibility of CNC machining surface treatment. Different treatment methods are suitable for different materials and shapes. For instance, some materials may not be suitable for sandblasting, while intricate shapes may pose challenges for manual polishing. Hence, a comprehensive consideration of factors like material, shape, and size is crucial when selecting a surface treatment method.

Production Efficiency:

Production efficiency is another critical factor influencing feasibility. Various surface treatment methods exhibit differences in production efficiency. Automated electroplating equipment, for instance, facilitates high-efficiency continuous production, whereas manual polishing may be time-consuming. Consequently, the impact of production efficiency on overall production planning needs to be thoroughly considered when choosing a surface treatment method.

Environmental Impact:

As environmental awareness grows, the environmental impact has become a crucial factor in assessing feasibility. Certain surface treatment processes may generate pollutants such as exhaust gases and wastewater, necessitating additional investments in environmental protection facilities. Hence, when selecting a surface treatment method, its environmental impact and the corresponding environmental protection inputs must be taken into account.

IV. Comprehensive Evaluation and Decision-Making:

Comprehensively evaluating the economic and feasibility aspects involves considering multiple factors, including cost, value, technical feasibility, production efficiency, and environmental impact. A holistic analysis of these factors provides decision-making support to CNC machining factories, enabling them to choose the most suitable surface treatment method.

Moreover, with continuous technological advancements and evolving market demands, CNC machining factories need to stay attuned to new technologies and methods. Regular optimization and updating of surface treatment processes are essential to adapt to market competition and meet customer demands.

In conclusion, evaluating the economic and feasibility aspects of CNC machining surface treatment is a complex yet crucial process. By comprehensively considering factors such as cost, value, technical feasibility, production efficiency, and environmental impact, CNC machining factories can make informed decisions, fostering continuous improvement and innovative development.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!