When it comes to material selection for manufacturing and construction, two metals often come up in discussion: copper and steel. But how do you choose between them? With distinct differences in their properties, costs, and applications, making the right choice can be difficult. Whether you’re working on custom CNC machining parts or determining which material to use for your next project, understanding the key differences between copper and steel is essential. This guide will help you weigh the pros and cons of each metal to make an informed decision based on your specific needs.

Copper is ideal for applications requiring excellent electrical and thermal conductivity, while steel is best for heavy-duty structural and industrial applications where strength and durability are critical. When deciding between copper vs. steel, consider factors like cost, application, and required properties. CNC machining services can help tailor these metals to meet your project’s unique needs.

As we dive deeper into the properties and applications of both metals, let’s first take a closer look at the basic differences between copper and steel. Understanding the types and properties of these metals is essential to make the right decision for your project.

When it comes to materials for manufacturing, two metals frequently come to mind: copper and steel. Both of these metals are used in a variety of applications across multiple industries, thanks to their unique properties. However, copper and steel have distinct characteristics that make each suitable for different types of projects, especially in CNC machining. In this article, we will compare copper and steel in terms of their composition, properties, applications, and surface treatments, helping you understand which metal is best for your specific needs.

Whether you are working with copper CNC machining parts or steel CNC machining parts, understanding the key differences between these metals will help you make an informed decision for your project.

Copper vs. Steel: Overview

What is Copper?

Copper is a reddish-brown metal that has been used for thousands of years. It is known for its excellent electrical and thermal conductivity, making it indispensable in electrical wiring, electronics, and heating systems. Copper is also highly corrosion-resistant, especially in moist environments, which is why it is often used in plumbing, roofing, and marine applications. Copper can be alloyed with other metals, such as tin (to form bronze) or zinc (to form brass), to enhance its properties.

What is Steel?

Steel, on the other hand, is an alloy primarily made from iron and carbon, with varying amounts of other elements such as manganese, chromium, and nickel. Steel is known for its strength, versatility, and durability, making it one of the most widely used materials in construction, automotive manufacturing, and industrial applications. The addition of other elements can modify its properties, resulting in various types of steel, each designed for specific purposes.

Copper vs. Steel: Types

Types of Copper

Copper is classified into several types, each offering distinct properties suitable for different applications. The most common types include:

- Pure Copper (Commercial Grade): This is the most common form of copper used in electrical wiring and plumbing. It is highly conductive but relatively soft.

- Alloyed Copper: Copper can be alloyed with elements such as zinc (brass), tin (bronze), and nickel (cupronickel), which increases its strength, hardness, and corrosion resistance.

- Oxygen-Free Copper: This is pure copper that has been refined to remove oxygen, making it ideal for applications that require high conductivity and minimal resistance.

Types of Steel

Steel comes in various forms, each designed to perform specific functions depending on its composition and intended use. Common types of steel include:

- Carbon Steel: This is the most common form of steel, with carbon as its main alloying element. It is affordable, versatile, and used in a wide range of applications, from construction to automotive manufacturing.

- Stainless Steel: Known for its resistance to corrosion, stainless steel contains chromium, which gives it its signature resistance to rust and tarnish. It's widely used in medical, kitchen, and industrial applications.

- Tool Steel: This type of steel is alloyed with elements like tungsten, vanadium, or molybdenum to enhance its hardness and wear resistance. It is typically used in cutting tools and molds.

- Alloy Steel: This is steel mixed with other metals like nickel, chromium, or manganese to provide specific properties such as increased strength, hardness, or heat resistance.

Copper vs. Steel: Comparison of their Properties

Chemical Composition

- Copper: Copper is primarily composed of pure copper, but its alloys (such as brass or bronze) may include additional elements like zinc or tin. These alloys are typically designed to improve strength or corrosion resistance while retaining the metal's characteristic conductivity.

- Steel: Steel's composition is largely made of iron and carbon. The amount of carbon in steel can vary, which directly impacts its hardness, flexibility, and weldability. Other elements, such as chromium or nickel, are often added to enhance the steel's corrosion resistance or strength.

Elemental Composition

- Copper: The pure form of copper is nearly 99% copper, with trace amounts of oxygen, iron, and other elements. Copper alloys are mixed with elements like zinc or tin to alter their characteristics.

- Steel: Steel typically contains 0.02% to 2% carbon, and the remainder is iron. Additional elements such as manganese, chromium, and nickel can significantly alter steel's properties, improving its corrosion resistance, tensile strength, or ductility.

Physical Properties

- Copper: Copper is a non-ferrous metal, meaning it doesn't contain iron. It is more malleable and ductile than steel and can be easily drawn into wire. It also has a lower melting point than steel, at about 1,984°F (1,085°C), compared to steel’s melting point of around 2,500°F (1,370°C).

- Steel: Steel is much stronger than copper and can withstand higher temperatures. It is more rigid, less malleable, and can be hardened through heat treatment processes. The strength of steel can vary significantly based on its alloy composition.

Mechanical Properties

- Copper: Copper is highly conductive, both thermally and electrically. However, it is softer than steel, making it less ideal for structural applications that require high strength. Copper is also more prone to wear and tear compared to steel.

- Steel: Steel is stronger and harder than copper, making it better suited for construction, manufacturing, and automotive applications. It is also more durable and resistant to wear, especially in alloyed forms like tool steel or stainless steel.

Electrical and Thermal Conductivity

- Copper: Copper is the best conductor of electricity among all metals. Its thermal conductivity is also high, which is why it's commonly used in electrical wiring and heat exchangers.

- Steel: Steel has lower electrical and thermal conductivity compared to copper, which makes it less suitable for electrical wiring. However, its strength and durability make it a preferred material in structural applications.

Weight

- Copper: Copper is much denser and heavier than steel, which can be a disadvantage in applications where weight is a concern.

- Steel: Steel is heavier than many other metals, but it offers much higher strength-to-weight ratios. In applications that require both strength and minimal weight, steel alloys, such as titanium alloy or carbon steel, are often preferred.

Corrosion Resistance

- Copper: Copper has excellent corrosion resistance, particularly in marine environments, where it naturally develops a patina over time. This makes it ideal for plumbing, marine, and electrical applications.

- Steel: Steel is prone to rust and corrosion when exposed to moisture, unless it is alloyed with chromium to form stainless steel. Stainless steel is highly resistant to corrosion, which is why it's widely used in food processing, medical equipment, and outdoor environments.

Hardness and Durability

- Copper: Copper is soft compared to steel, making it more susceptible to wear and tear. However, when alloyed with other metals, its hardness and durability can be improved.

- Steel: Steel is hard, durable, and able to withstand heavy loads, impacts, and extreme conditions. It is much more durable than copper in industrial applications.

Tensile Yield Strength

- Copper: Copper’s tensile strength is lower than steel’s, which limits its use in load-bearing applications. However, its ability to deform without breaking makes it suitable for applications that require high ductility, such as wiring.

- Steel: Steel has high tensile yield strength, which makes it the material of choice for structural applications that require resistance to tension, pressure, and bending.

Price and Cost

- Copper: Copper is significantly more expensive than steel, primarily due to its extraction process and relatively limited supply compared to iron, which is used in steel production.

- Steel: Steel is relatively inexpensive and widely available, making it the more economical choice for many industrial applications. Its cost varies depending on the alloying elements used.

Processability

- Copper: Copper is relatively easy to machine, and its malleability makes it easy to form and shape. However, its softness may cause wear on machining tools during production.

- Steel: Steel is more challenging to machine than copper, especially harder steel alloys. However, its strength and versatility in the final product often outweigh this challenge.

Copper vs. Steel: Their Application Industries and Parts

Applications of Copper

Copper is widely used in industries where high electrical or thermal conductivity is essential:

- Electrical and Electronics: Copper is used extensively in wiring, electrical connectors, and circuit boards due to its excellent electrical conductivity.

- Plumbing and Roofing: Copper’s resistance to corrosion makes it an ideal material for plumbing pipes and roofing materials.

- Automotive: Copper alloys are used in various automotive components, including radiators, brakes, and electrical systems.

- Renewable Energy: Copper plays a significant role in solar panels and wind turbines, where its conductivity and durability are critical.

Applications of Steel

Steel is the go-to material in industries where strength, durability, and versatility are key:

- Construction: Steel is used for structural support in buildings, bridges, and other large-scale construction projects.

- Automotive: Steel is used extensively in vehicle frames, chassis, and engine components.

- Manufacturing: Steel is used in machinery, tools, and production lines due to its hardness and strength.

- Medical: Stainless steel is commonly used in surgical instruments, implants, and medical devices.

- Food and Beverage Industry: Stainless steel is widely used in food processing, storage, and kitchen equipment due to its corrosion resistance, cleanliness, and ease of maintenance.

- Aerospace and Defense: Steel alloys, particularly stainless and tool steels, are essential in aerospace and defense for producing aircraft parts, missile components, and military equipment that require strength and resistance to extreme conditions.

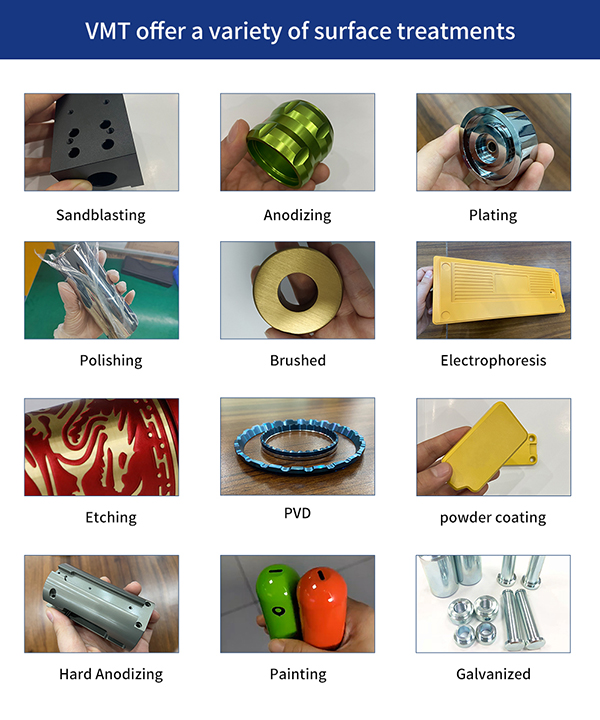

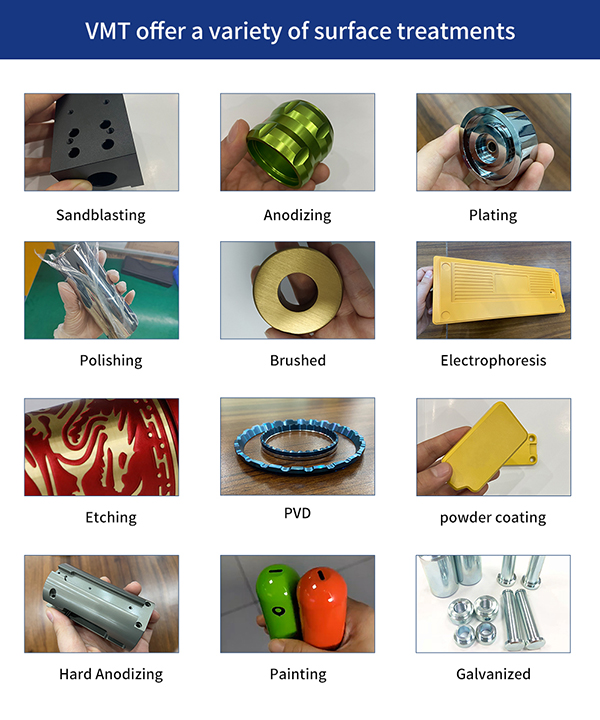

What Surface Treatments Can Be Done on Copper Parts?

Copper can undergo various surface treatments to improve its appearance, corrosion resistance, or hardness:

- Oxidation: Copper naturally forms a green patina when exposed to air, which helps protect it from further corrosion. This can be accelerated artificially for aesthetic purposes or to create a more durable finish.

- Electroplating: Copper is often used as a base metal for electroplating, where a thin layer of another metal (such as nickel or gold) is applied to enhance the surface properties like wear resistance or conductivity.

- Annealing: Annealing softens copper, making it more malleable and easier to work with in processes such as forming or bending.

- Polishing: Polishing is often done to give copper a shiny, reflective finish, which is useful in decorative applications like jewelry and home decor.

What Surface Treatments Can Be Done on Steel Parts?

Steel parts also benefit from a variety of surface treatments, depending on the specific requirements of the application:

- Galvanizing: Galvanizing involves coating steel with a layer of zinc to protect it from corrosion. This is particularly useful in outdoor and marine environments.

- Passivation: This process involves treating stainless steel with acid solutions to remove free iron from the surface, enhancing its resistance to corrosion and improving its aesthetic finish.

- Heat Treatment: Heat treatment processes like quenching, tempering, and annealing are used to change the hardness, strength, and ductility of steel. These processes are crucial in applications requiring high tensile strength or toughness.

- Coatings: Steel can be coated with paints, powders, or other finishes to enhance its aesthetic appeal and protect it from the environment. In industries like automotive manufacturing, coatings are essential for durability and corrosion resistance.

Copper vs. Steel – Pros and Cons of Each Metal

Pros of Copper

- Excellent Conductivity: Copper is the best conductor of electricity and heat, making it indispensable in electrical applications.

- Corrosion Resistance: Copper resists corrosion from moisture and atmospheric elements, which makes it ideal for plumbing, roofing, and marine applications.

- Ductility: Copper can be easily formed into various shapes without breaking, allowing for greater flexibility in design and manufacturing.

- Antibacterial Properties: Copper has natural antimicrobial properties, making it an excellent choice for medical devices and environments where hygiene is critical.

Cons of Copper

- High Cost: Copper is more expensive than steel, which can make it less appealing for large-scale construction and industrial applications.

- Softness: Copper is relatively soft, making it more prone to wear and tear compared to steel, especially in high-stress applications.

- Tarnishing: Over time, copper develops a patina or greenish tarnish, which may not be desirable for certain aesthetic applications, although this can be controlled or avoided with proper finishing techniques.

Pros of Steel

- Strength and Durability: Steel is one of the strongest materials available, offering superior mechanical properties for structural applications.

- Versatility: Steel is available in a wide variety of grades and alloys, which can be tailored for specific applications, from automotive to aerospace and construction.

- Cost-Effective: Steel is more affordable than copper, especially in bulk, making it a go-to material for many industrial applications.

- Corrosion Resistance (Stainless Steel): Stainless steel offers excellent resistance to rust and corrosion, making it suitable for harsh environments and applications where hygiene is a concern.

Cons of Steel

- Weight: Steel is denser and heavier than copper, which can be a disadvantage in applications where weight reduction is crucial, such as in aerospace or automotive sectors.

- Corrosion in Unalloyed Steel: While stainless steel is highly resistant to corrosion, unalloyed carbon steel can rust easily when exposed to moisture or chemicals, requiring additional coatings or treatments.

- Machining Difficulty: Steel, especially hardened steel, can be challenging to machine. It requires more advanced tools and techniques to achieve precise parts, which can increase manufacturing costs.

Copper vs. Steel: Which Metal Should You Use?

Choosing between copper and steel depends on various factors, such as cost, performance requirements, and the intended application. Here’s a breakdown of how to make the decision:

Cost

- Copper: Copper is more expensive than steel, making it less attractive for projects where cost is a primary consideration. However, if electrical conductivity or corrosion resistance is a priority, the higher cost may be justified.

- Steel: Steel is generally more affordable and widely available. It is the go-to material for many industries due to its strength and cost-effectiveness.

Applications

- Copper: Choose copper for electrical, plumbing, and architectural applications, where its high conductivity and corrosion resistance are key. Copper is ideal for electronics, wiring, heat exchangers, and decorative items.

- Steel: Steel is the preferred material for structural components, construction, automotive, and heavy machinery. Its strength and durability make it suitable for industries where high load-bearing capacity and resistance to wear are critical.

Machinability

- Copper: Copper is easier to machine and fabricate than steel, making it a good choice for intricate parts and fine details in industries such as electronics or jewelry.

- Steel: Steel is more difficult to machine, especially higher-carbon steels. However, steel’s strength and versatility outweigh these challenges in many applications, such as heavy-duty manufacturing.

Processing Waste

- Copper: Copper tends to produce less waste during machining due to its malleability and ease of forming.

- Steel: Steel may produce more waste during machining, especially in high-strength alloys, which require specialized tools and techniques.

Aesthetic Requirements

- Copper: Copper is often chosen for its unique appearance, especially in architectural and decorative applications. Its reddish-brown hue and ability to develop a patina make it a visually appealing material.

- Steel: Steel is versatile in aesthetics, especially stainless steel, which offers a sleek, modern finish. It’s often used for appliances, kitchenware, and automotive parts where both strength and appearance matter.

VMT: Copper and Steel CNC Machining Service Manufacturing Capabilities

At VMT, we specialize in custom CNC machining services for both copper and steel parts. Our advanced CNC machining capabilities allow us to create precise, high-quality components for industries ranging from aerospace and automotive to electronics and medical. Whether you need copper CNC machining parts or steel CNC machining parts, our expertise in CNC prototype machining ensures that your projects are completed on time and within budget. We work closely with you to optimize the design and material selection process, ensuring the best outcome for your manufacturing needs.

Conclusion

Copper and steel are both excellent materials with distinct advantages depending on the application. Copper is ideal for electrical and heat transfer applications due to its high conductivity, while steel offers superior strength, durability, and versatility for structural and industrial uses. Understanding the properties, costs, and machining challenges associated with each metal will help you choose the best option for your specific project.

FAQ – Copper vs. Steel

Is copper stronger than steel?

No, steel is stronger than copper. Steel has a higher tensile strength, which makes it more suitable for structural and high-stress applications.

What is the hardest metal to cut?

The hardest metal to cut is typically tungsten or certain types of hardened steel, due to their extreme hardness.

Does copper rust faster than steel?

Copper does not rust, but it forms a green patina (copper oxide) over time when exposed to air. Steel, especially carbon steel, rusts when exposed to moisture unless properly treated.

Why is copper used instead of steel?

Copper is used over steel in applications where high electrical conductivity, corrosion resistance, or heat transfer is required, such as in electrical wiring and plumbing.

Why is copper so expensive?

Copper is more expensive because it is rarer than steel and requires more energy-intensive extraction and refinement processes.

Which metal is called the king of metals?

Gold is often referred to as the "king of metals" due to its rarity, value, and historical significance.

Why is copper the most important metal?

Copper is crucial because of its unique properties such as electrical conductivity, corrosion resistance, and versatility in a wide range of applications.

Why does copper turn green?

Copper turns green due to the formation of copper oxide (patina) when exposed to air and moisture. This patina helps protect the metal from further corrosion.

Which metal doesn’t rust?

Stainless steel and certain other alloys, like titanium and aluminum, do not rust due to their protective oxide layers.

How many years does it take for copper to rust?

Copper doesn't rust in the traditional sense, but it can develop a green patina over several years, depending on environmental conditions.

Is titanium stronger than steel?

Titanium is stronger than many metals in terms of strength-to-weight ratio, but steel is generally stronger overall in terms of absolute tensile strength.

1646 |

Published by VMT at Jan 24 2025 | Reading Time:About 3 minutes

1646 |

Published by VMT at Jan 24 2025 | Reading Time:About 3 minutes