15 years one-stop China custom CNC machining parts factory

310 |

Published by VMT at Jan 23 2025 | Reading Time:About 4 minutes

310 |

Published by VMT at Jan 23 2025 | Reading Time:About 4 minutes

When selecting materials for custom CNC machining projects, two of the most commonly considered metals are titanium and stainless steel. However, understanding the key differences between these two alloys can be challenging, especially when it comes to their properties, cost-effectiveness, and specific application areas.

Choosing the wrong material for CNC prototype machining can lead to project delays, higher costs, and suboptimal performance of the finished product. The wrong material might not withstand the required stress, temperature fluctuations, or corrosion conditions, compromising the final result.

This article will provide a detailed comparison of titanium and stainless steel, outlining their properties, advantages, disadvantages, and applications. With this knowledge, you’ll be able to make an informed decision on whether titanium CNC machining parts or stainless steel CNC machining parts are the best choice for your next project.

Titanium and stainless steel are both popular choices for CNC machining, offering distinct advantages in various applications. Titanium alloys are known for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal for aerospace and medical applications. Stainless steel, on the other hand, is more cost-effective, easier to machine, and offers excellent heat resistance, making it suitable for a wide range of industrial uses. Understanding these differences will help you determine the best material for your specific CNC machining needs.

Now that we’ve introduced the main factors to consider when choosing between titanium and stainless steel, let’s dive deeper into their chemical compositions, physical properties, and mechanical characteristics. This comparison will give you a clearer picture of how these two materials perform under different conditions and what makes them suited for various CNC machining projects.

Introduction: Understanding Titanium and Stainless Steel for CNC Machining

When it comes to CNC machining, selecting the right material is crucial for achieving optimal results. Among the most frequently used metals in the industry are titanium and stainless steel. These two alloys are known for their strength, durability, and versatility, but they each come with distinct characteristics that make them suitable for different applications. For custom CNC machining, knowing how to compare titanium and stainless steel — including their chemical composition, mechanical properties, surface treatments, and costs — is vital to making the right choice.

In this article, we’ll explore the key differences and similarities between titanium and stainless steel. From their respective grades to their unique benefits and drawbacks, we’ll examine how each metal performs in CNC machining processes. Whether you’re considering titanium CNC machining parts for aerospace or medical uses, or stainless steel CNC machining parts for industrial applications, this comprehensive guide will help you make an informed decision.

Before diving into the comparative analysis of titanium and stainless steel, it’s important to understand the different grades and types of each metal. Both alloys come in various forms that affect their properties and suitability for specific machining applications. This section will give an overview of the primary types of titanium and stainless steel alloys.

Titanium Alloys: Grades and Types

Titanium is a lightweight, corrosion-resistant metal with outstanding strength. There are several grades of titanium alloys, each designed to meet different performance requirements. The key grades for CNC machining include:

CP Grades 1-2 (Commercially Pure Titanium)

Commercially pure titanium (CP) is available in grades 1 through 4, with Grade 1 being the softest and most ductile, and Grade 4 being the strongest. These grades are typically used in applications that require high corrosion resistance but don’t demand exceptional strength. CP titanium is widely used in medical implants, aerospace, and chemical processing industries.

CP Grades 3-4

CP Grade 3 and Grade 4 offer slightly higher strength than Grades 1 and 2, with Grade 4 providing the highest strength of the CP grades. These alloys are often used in applications where strength and corrosion resistance are critical, such as heat exchangers or high-performance automotive components.

Ti 6Al-4V (Grade 5)

Ti 6Al-4V, or Grade 5 titanium, is the most commonly used titanium alloy, consisting of 90% titanium, 6% aluminum, and 4% vanadium. This alloy provides excellent strength, making it ideal for aerospace, automotive, and military applications. Ti 6Al-4V is commonly used in custom CNC machining for parts that need to withstand high stress and fatigue, such as turbine blades and structural components in aircraft.

Each grade of titanium has distinct properties that make it suited to different applications in CNC machining. Titanium alloys generally exhibit excellent corrosion resistance, high strength, and biocompatibility, which makes them ideal for demanding environments such as medical and aerospace fields.

Stainless Steel Alloys: Types and Grades

Stainless steel, like titanium, is a versatile material used in CNC machining, known for its ability to resist corrosion, heat, and mechanical wear. Stainless steel alloys come in several families, each with unique characteristics:

Austenitic Stainless Steel

Austenitic stainless steels are the most commonly used type, known for their excellent corrosion resistance, formability, and weldability. Grades such as 304 and 316 fall into this category. Austenitic steels are non-magnetic and have good strength at both high and low temperatures, making them ideal for applications in the food industry, medical devices, and chemical processing.

Martensitic Stainless Steel

Martensitic stainless steels are known for their high strength and hardness. They are less resistant to corrosion compared to austenitic steels but are often used for parts that require wear resistance, such as cutting tools and valves. Common grades include 410 and 420. These alloys are frequently used in CNC machining for their ability to be hardened through heat treatment.

Ferritic Stainless Steel

Ferritic stainless steels are magnetic and offer good resistance to stress corrosion cracking and high-temperature oxidation. However, they are not as formable as austenitic steels. They are commonly used in automotive exhaust systems, industrial equipment, and architectural applications. Grades like 430 are common in this family.

Duplex Stainless Steel

Duplex stainless steels combine the properties of austenitic and ferritic steels. These alloys offer high strength and excellent resistance to pitting corrosion. They are commonly used in the oil and gas industry, as well as in chemical and marine applications. Duplex stainless steels, like 2205, provide superior performance in aggressive environments.

Precipitation Hardening Stainless Steel

Precipitation hardening stainless steels, such as 17-4 PH, are alloys that can be hardened through heat treatment, resulting in increased strength and hardness. These alloys are commonly used in high-stress applications, such as aerospace components and valves, where high strength and fatigue resistance are required.

Each type of stainless steel has its strengths and weaknesses, making it important to choose the right alloy based on the specific requirements of your CNC machining project.

Now that we’ve discussed the various types of titanium and stainless steel alloys, it’s important to compare their overall properties. While both metals are known for their strength and durability, they have different characteristics that influence their performance in different applications.

Titanium and Stainless Steel: Chemical Composition

The chemical composition of a material plays a significant role in determining its properties, such as strength, corrosion resistance, and heat tolerance. Titanium, in its pure form, is highly resistant to corrosion, even in harsh environments like seawater or chemicals. Its alloys, like Ti 6Al-4V, enhance strength while maintaining good corrosion resistance.

On the other hand, stainless steel is made primarily of iron, chromium (usually around 10-30%), and other alloying elements like nickel, molybdenum, and manganese. The presence of chromium is what gives stainless steel its corrosion-resistant properties. The higher the chromium content, the better the material will resist corrosion, but it can also influence other properties like machinability and strength.

Titanium alloys tend to have superior corrosion resistance compared to stainless steel, especially in environments with high salinity or chemicals. However, stainless steel alloys like 316 offer good corrosion resistance in less extreme conditions.

Titanium and Stainless Steel: Physical Properties

Titanium and Stainless Steel: Mechanical Properties

To help determine the best material for your CNC machining project, it's important to consider the advantages and disadvantages of both titanium and stainless steel.

Advantages of Titanium

Disadvantages of Titanium

Advantages of Stainless Steel

Disadvantages of Stainless Steel

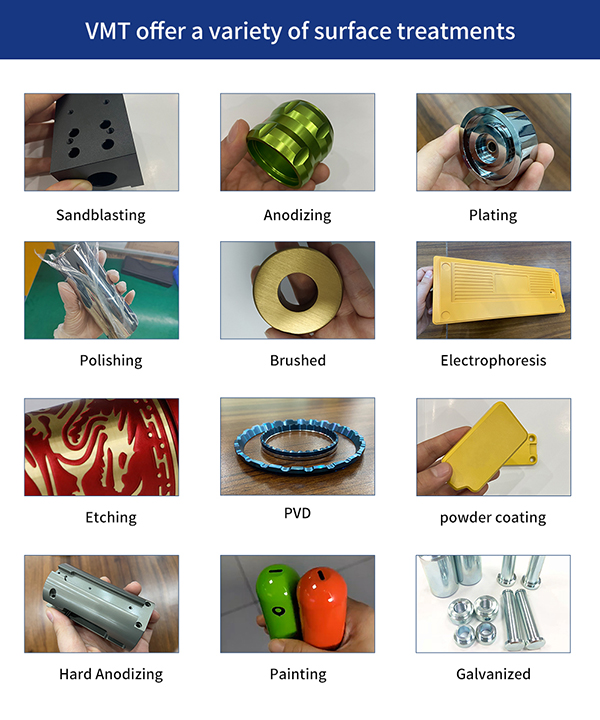

Surface treatments play a crucial role in improving the performance and lifespan of CNC machined parts. Both titanium and stainless steel benefit from various treatments that enhance their corrosion resistance, hardness, and overall durability. Understanding these treatments is essential when choosing the right material for your CNC machining project.

What Surface Treatments Can Be Applied to Titanium Parts?

Titanium’s naturally occurring oxide layer makes it highly resistant to corrosion. However, various surface treatments can further enhance its properties depending on the application. Some of the most common surface treatments for titanium include:

What Surface Finishes Are Available for Stainless Steel Parts?

Stainless steel, known for its high corrosion resistance and mechanical properties, also benefits from several surface treatments that can improve its appearance, performance, and longevity. Some of the most popular surface finishes for stainless steel include:

Both titanium and stainless steel are widely used across various industries due to their unique properties. Understanding the common applications of these two metals can help you choose the right material for your CNC machining project.

Applications of Titanium

Titanium is highly valued for its high strength, low weight, and corrosion resistance. These characteristics make it ideal for use in demanding applications such as:

Applications of Stainless Steel

Stainless steel’s versatility, strength, and corrosion resistance make it a go-to material in a wide range of industries. Some common applications of stainless steel include:

When deciding between titanium and stainless steel for CNC machining, cost is often a critical factor. Both materials have distinct pricing structures that can impact the overall cost of your project, especially when producing large quantities or highly intricate parts.

Price Per Pound

Titanium is significantly more expensive than stainless steel, largely due to the complexity of its extraction, processing, and alloying. Titanium is more challenging to refine, and its extraction requires more energy, driving up costs. Stainless steel, on the other hand, is more readily available and cheaper to process. As a result, stainless steel is often the preferred material for large-scale production where cost-effectiveness is crucial.

Availability

Stainless steel is far more abundant and widely available than titanium, contributing to its lower price. In contrast, titanium’s limited availability — particularly certain high-performance grades like Ti 6Al-4V — makes it a more expensive option. This could impact project timelines if material availability is a concern, as titanium may need to be sourced from specific suppliers.

Manufacturing Costs

Titanium requires more specialized machining techniques due to its hardness and tendency to work-harden. As a result, machining titanium parts can be more expensive, requiring higher tool wear rates and slower processing times. Stainless steel is easier to machine and generally requires less investment in tooling, making it a more cost-effective option for CNC machining in most cases.

While both titanium and stainless steel offer superior strength and durability, they each present unique challenges during the CNC machining process. Understanding these challenges is essential for achieving high-quality parts and optimizing production costs.

Titanium Processing Challenges

Stainless Steel Processing Challenges

Both titanium and stainless steel offer distinct advantages for CNC machining projects, with each metal being suitable for specific applications based on its properties, cost, and processing requirements. Titanium’s exceptional strength-to-weight ratio, biocompatibility, and corrosion resistance make it the material of choice for aerospace, medical, and high-performance applications. Stainless steel, on the other hand, is more cost-effective, easier to machine, and highly versatile, making it ideal for industrial, automotive, and consumer goods applications.

Ultimately, the decision between titanium and stainless steel dependson the specific requirements of your project, including factors such as performance, cost, and manufacturing capabilities. To make the best choice, it’s essential to evaluate the following considerations:

As sustainability becomes increasingly important, it’s essential to consider the environmental impact of your material choices. Both titanium and stainless steel offer benefits in terms of durability and recyclability, but they also present unique challenges in terms of energy consumption and extraction processes.

Energy Consumption

Titanium extraction is a highly energy-intensive process. The production of titanium metal from ore requires significant energy, particularly in the Kroll process, which involves high temperatures and the use of chemicals. This process makes titanium production more energy-consuming than stainless steel manufacturing.

In contrast, stainless steel production, while also energy-intensive, is generally less so compared to titanium. The process of making stainless steel involves the melting of scrap steel, which can significantly reduce the energy requirements if scrap material is used. Stainless steel can also be recycled multiple times without significant degradation of its properties, which adds to its sustainability.

Recyclability

Both titanium and stainless steel are highly recyclable materials, making them more sustainable compared to other metals. Titanium can be recycled and reused in various industries, though the process is more complex due to the material's high melting point and the potential for contamination during recycling.

Stainless steel, on the other hand, is one of the most widely recycled metals in the world. The recycling process for stainless steel is relatively straightforward, and it can be recycled indefinitely without losing its strength or quality. This makes stainless steel a highly sustainable option, especially for industries that prioritize environmental impact.

Material Weight and Durability

From an environmental perspective, the durability and longevity of the materials also play a role in their overall sustainability. Titanium’s strength-to-weight ratio makes it an excellent choice for applications where reducing material usage is a priority, such as in aerospace and automotive industries. Its long lifespan and resistance to corrosion also mean that products made from titanium can remain in use longer, reducing the need for replacement.

Stainless steel is also durable and resistant to corrosion, which makes it ideal for applications in harsh environments. Its longevity and minimal maintenance requirements contribute to its sustainability, particularly in industries like construction, automotive, and food processing.

Should You Choose Titanium or Stainless Steel for Your CNC Machining Project?

Ultimately, the decision between titanium and stainless steel will depend on several factors, including price, application, and project-specific requirements. Both materials offer unique advantages, and understanding these properties can help you make an informed decision.

Key Considerations:

When comparing titanium and stainless steel for cookware, each metal offers distinct advantages.

Ultimately, your choice of material for cookware will depend on your needs. Titanium offers a lightweight and corrosion-resistant option, while stainless steel offers better heat conductivity and affordability.

When it comes to machines and industrial components, titanium and stainless steel each offer unique benefits.

Choosing between titanium and stainless steel for your CNC machining project requires a careful evaluation of your application’s specific needs. Titanium is the better choice for applications where weight, strength, and corrosion resistance are paramount, while stainless steel offers a more cost-effective, easy-to-machine alternative for a wide range of industrial uses.

At VMT, we provide both titanium and stainless steel CNC machining services, offering custom parts tailored to your project’s requirements. Our state-of-the-art CNC machining factory specializes in producing high-precision titanium CNC machining parts and stainless steel CNC machining parts for a variety of industries. Whether you’re working on aerospace, medical, automotive, or industrial applications, our CNC prototype machining and CNC machining services are designed to meet the highest standards of quality and efficiency.

1. Which is better, titanium plate or stainless steel plate?

Titanium is better for high-performance, corrosion-resistant applications, while stainless steel is more cost-effective and better suited for industrial and heavy-duty applications.

2. Is titanium steel better than stainless steel?

Titanium offers superior corrosion resistance and strength-to-weight ratio, making it ideal for aerospace and medical uses. Stainless steel is more cost-effective and easier to machine, making it better for industrial and commercial applications.

3. Which is more expensive, stainless steel or titanium alloy?

Titanium is significantly more expensive than stainless steel due to the complexity of its extraction and machining processes.

4. Is titanium lighter than stainless steel?

Yes, titanium is lighter than stainless steel, making it ideal for applications where weight is a critical factor.

5. Is titanium stronger than steel?

Titanium has a higher strength-to-weight ratio than steel, making it stronger per unit of weight. However, stainless steel can offer higher overall strength in some forms.

6. What are the disadvantages of titanium watches?

Titanium watches are more expensive, prone to scratches, and may require specialized tooling for repairs, but they are incredibly lightweight and resistant to corrosion.

7. Does titanium steel rust?

Titanium does not rust because it forms a protective oxide layer. Stainless steel can rust, but high-quality grades like 316 offer excellent resistance to corrosion.

8. Does titanium cause inflammation in the body?

Titanium is biocompatible, meaning it doesn’t typically cause inflammation or allergic reactions in the body, which is why it is widely used in medical implants.

9. Which is harder to scratch, stainless steel or titanium?

Titanium is harder to scratch than stainless steel, making it ideal for high-durability applications.

This concludes our in-depth guide to understanding the differences between titanium and stainless steel for CNC machining. By considering factors like performance, cost, and application, you can make the best material choice for your project. If you need high-quality CNC machining parts, VMT’s expert team is ready to provide custom solutions tailored to your exact specifications.