15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

818 |

Published by VMT at Aug 07 2024

818 |

Published by VMT at Aug 07 2024

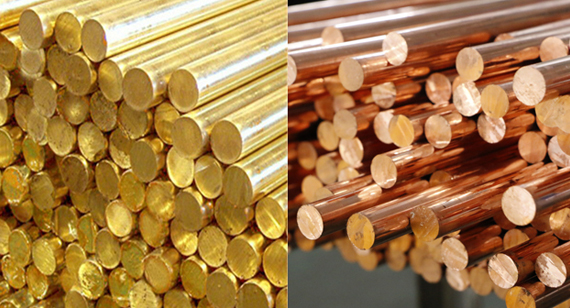

Brass and copper, while often confused due to their similar names, differ significantly in their material properties, applications, and processing methods. This article explores these differences in detail, covering ten key aspects: elemental composition, corrosion resistance, weight, durability, machinability, weldability, conductivity, strength, appearance, and hardness. It also includes an overview of red copper and brass, quick identification methods, factors affecting their longevity, and recommendations for material selection in projects.

1. Elemental Composition

Brass:

Brass is an alloy of copper and zinc, typically containing about 60% copper, with the rest being zinc and small amounts of other metals. Brass can be classified into single-phase brass (α brass), duplex brass (α+β brass), and special brass (with added elements like Sn, Mn, Al, Fe, Ni). The alloying process gives brass unique physical and chemical properties suitable for various applications.

Copper:

Copper, symbolized as Cu, is a pure metal. High-purity copper, known as red or pure copper, contains 99.5% to 99.95% copper. Due to its excellent electrical and thermal conductivity and good corrosion resistance, copper is widely used in electrical, construction, and artistic fields.

2. Corrosion Resistance

Brass:

Brass corrodes slowly in the atmosphere and fresh water but corrodes faster in seawater. Its corrosion resistance depends on the alloy elements; adding Sn can enhance seawater resistance, while chlorides and iodides can corrode brass more aggressively. Brass is prone to stress corrosion cracking, influenced by the medium, stress, alloy composition, and microstructure.

Copper:

Pure copper has good corrosion resistance due to its high purity and dense crystal structure. It forms a protective patina (copper green) in natural environments, which prevents further corrosion. However, acidic or alkaline conditions can affect its resistance.

3. Weight

Brass has a density of 8.52-8.93 g/cm³, while pure copper's density is 7.62-7.83 g/cm³. Brass is approximately 5% heavier than pure copper, which is significant in manufacturing large metal products.

4. Durability

Brass, with higher hardness and wear resistance, is used for parts subjected to mechanical stress, such as door handles and locks. Its higher embrittlement temperature makes it stable in high-temperature environments. Pure copper, although softer and more ductile, is less suitable for high-strength and wear-resistant applications.

5. Machinability

Brass:

Brass has excellent machinability, suitable for casting, forging, stamping, and CNC machining parts due to its alloy properties.

Copper:

Pure copper also has good machinability but requires careful handling to prevent deformation and scratching due to its high ductility and softness. It has excellent weldability but requires control over the heat-affected zone and porosity during welding.

6. Weldability

Both brass and copper have unique welding characteristics. Brass requires careful control to avoid zinc evaporation and burn-off. Pure copper, with high thermal conductivity and the presence of low melting point eutectics, is prone to hot cracking and porosity, necessitating appropriate preheat and post-weld heat treatment.

7. Conductivity (Electrical and Thermal)

Copper:

Pure copper is an excellent conductor of electricity and heat, making it indispensable in electrical, electronic, and thermal conduction applications.

Brass:

Brass has lower electrical and thermal conductivity due to the presence of zinc and other elements. However, it is still used in applications where high conductivity is not critical.

8. Strength (Tensile and Yield Strength)

Brass has higher strength, including tensile and yield strength, due to the formation of solid solutions and intermetallic compounds during alloying. Pure copper, while soft and ductile, is not as strong as brass.

9. Appearance

Brass:

Brass ranges from light gold to deep yellow in color, with a unique metallic luster. The color varies with zinc content, becoming more gold-like with higher zinc levels.

Copper:

Pure copper has a reddish-brown color, giving a warm and noble texture. It forms a green patina upon oxidation, which does not affect its intrinsic properties.

10. Hardness

Brass is generally harder than pure copper, mainly due to the formation of strengthening phases during alloying. While pure copper is soft and easy to work with, brass can be further hardened by adjusting the alloy composition and heat treatment.

Copper Grades:

Red copper, or pure copper, comes in various grades (e.g., T1, T2, T3) based on purity and impurity levels, catering to different industry requirements.

Applications:

Red copper is widely used in electrical, electronic, construction, art, and craft manufacturing due to its superior conductivity, thermal properties, and corrosion resistance.

Brass Grades:

Brass grades vary based on zinc content and other alloy elements (e.g., H62 with 62% zinc). Different grades have distinct physical and chemical properties for various applications.

Applications:

Brass is used in hardware, valves, pipe fittings, decorative items, and artistic pieces due to its machinability, corrosion resistance, strength, and aesthetic appeal.

Color: Brass is yellowish, while pure copper is reddish-brown.

Sound: Brass sounds dull when struck, while copper produces a clearer sound.

Density: Brass is denser than pure copper, measurable with a density meter.

Composition: Chemical or spectroscopic analysis can accurately determine the material's composition.

Durability: Brass is more wear-resistant and corrosion-resistant than pure copper.

Magnetism: Pure copper is non-magnetic, while some brass alloys with iron may show weak magnetism.

Composition: Alloy composition affects physical and chemical properties.

Environmental Conditions: Harsh environments accelerate corrosion and aging.

Moisture Exposure: Moisture promotes electrochemical corrosion.

Mechanical Stress: Mechanical stress leads to fatigue or deformation.

pH Value: pH changes influence corrosion rates.

Maintenance: Regular cleaning, painting, or coating extends life.

Chemical Exposure: Avoid contact with harmful chemicals.

Design and Installation: Proper design reduces stress and impacts.

Operating Temperature: High temperatures accelerate oxidation and corrosion.

Usage Frequency: Frequent use increases wear and fatigue.

Coatings and Surface Treatments: Appropriate coatings enhance corrosion resistance.

Machinability:

Both materials are machinable, but brass, being harder, requires careful tool selection and cutting parameters. Choose the right material and specifications to ensure machining efficiency and product quality.

Applications:

Select based on specific application requirements. Copper is ideal for electrical applications due to its conductivity, while brass's aesthetic appeal and corrosion resistance make it suitable for high-end decorative and hardware products.

Price:

Copper is generally more expensive due to its purity and excellent properties, whereas brass is more affordable. Consider market conditions, alloy composition, and purity when budgeting for your project.

As a professional CNC machining factory, VMT has advanced CNC prototype processing equipment and rich processing experience. We are committed to providing customers with customized CNC machining services, including brass CNC machining parts and copper CNC machining parts. No matter how complex your project requirements are, VMT can provide high-quality machining solutions to ensure product accuracy and delivery time. Choose VMT to make your metal processing and prototyping projects easier and more efficient.

Brass and copper differ in elemental composition, corrosion resistance, weight, durability, machinability, weldability, conductivity, strength, appearance, and hardness. Understanding these differences helps in selecting the appropriate material for specific project needs, enhancing product performance and longevity. Proper design, installation, and maintenance further extend the lifespan of brass and copper products, reducing maintenance costs. For metal processing services, choose a professional and experienced machining factory like VMT to ensure product quality and timely delivery.

Which is better, brass or copper?

Both have unique advantages and applications; the choice depends on project needs, performance requirements, and budget.

Pure copper forms a protective patina, preventing further corrosion. Brass has good corrosion resistance but may corrode in harsh environments. Proper coatings can enhance brass's corrosion resistance.

Which is more expensive, brass or copper?

Generally, pure copper is more expensive due to its high purity and excellent properties, while brass is more cost-effective, depending on market conditions and alloy composition.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!