15 years one-stop China custom CNC machining parts factory

622 |

Published by VMT at Jul 26 2024

622 |

Published by VMT at Jul 26 2024

Aluminum extrusion, also known as aluminum extrusion forming, is a plastic processing method where aluminum billets heated to a plastic state are placed in a mold cavity (or extrusion cylinder) and forced to undergo directional plastic deformation under strong pressure. The aluminum billets are then extruded through the mold's die holes to obtain parts or semi-finished products with the desired cross-sectional shape, size, and certain mechanical properties. This process not only enhances the deformability of aluminum alloys but also ensures comprehensive product quality, making it widely applicable. Depending on the extrusion direction, aluminum extrusion processes can be categorized into direct extrusion, indirect extrusion, and side extrusion, each suited to specific production needs.

High Strength and Hardness: Extruded aluminum profiles possess high strength and hardness, making them capable of withstanding significant pressure and load, suitable for various applications.

Lightweight: Compared to other metal materials, extruded aluminum profiles have lower density and weight, making them easy to handle and install, especially in fields with strict weight requirements such as aerospace and transportation.

Corrosion Resistance: Extruded aluminum profiles exhibit excellent corrosion resistance at room temperature, being less prone to oxidation and corrosion, thus extending the product's lifespan.

Excellent Thermal Conductivity: Extruded aluminum profiles have good thermal conductivity, capable of rapidly conducting heat, making them ideal for manufacturing heat exchangers like radiators.

Good Machinability: Extruded aluminum profiles are easy to process and form, allowing for various machining methods such as cutting, welding, and polishing to achieve diverse shapes and sizes.

Aluminum casting is a process where pure aluminum or aluminum alloy ingots are heated to a molten state and then poured into molds to cool and solidify. This method, with a long history and mature technology, can produce aluminum products with various complex shapes according to requirements. Common aluminum casting methods include sand casting, die casting, low-pressure casting, precision casting, and permanent mold casting, each with unique advantages and application areas.

Shape Versatility: Aluminum casting can produce parts with complex shapes and fine structures, meeting various design requirements.

High Strength and Durability: Aluminum alloy castings have high strength and durability, maintaining stable performance in harsh environments, making them ideal for power machinery, aerospace, and chemical industries.

High Surface Finish: Aluminum castings have smooth and delicate surfaces that often do not require additional polishing, suitable for decorative, household, and furniture manufacturing.

Recyclability: The raw materials for aluminum castings can be recycled, reducing production costs and aligning with sustainable development principles.

Cost-Effectiveness: With mature casting technology and high production efficiency, aluminum casting is suitable for mass production, offering significant cost advantages.

Cast Aluminum

Cast aluminum is a process where molten aluminum alloy is poured into a mold matching the desired part shape, then allowed to cool and solidify. This method is suitable for producing parts with complex shapes, thin walls, or internal cavities.

Characteristics:

Good Fluidity and Machinability: Can form complex geometries and has relatively low production costs.

Production: The casting process includes melting, pouring, cooling, and finishing steps.

Applications: Widely used in automotive, aerospace, architectural decoration, and electrical equipment industries.

Advantages: Capable of producing complex-shaped parts, high production efficiency, and high material utilization.

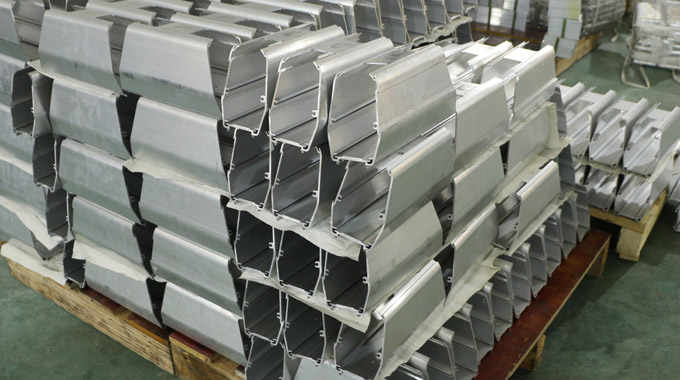

Extruded Aluminum

Extruded aluminum is a process where aluminum alloy is heated to a certain temperature, then forced through a die using an extrusion machine to form long materials with a specific cross-sectional shape.

Characteristics:

High Strength, Hardness, and Wear Resistance: Primary properties such as strength and hardness meet national standards.

Production: The extrusion process allows for continuous production with high efficiency, suitable for mass production.

Applications: Widely used in construction structures, transportation, and industrial sectors, such as window and door frames, vehicle body components, and mechanical parts.

Advantages: Lightweight, rust-resistant, fast design changes, low mold investment, and capable of longitudinal elongation up to 10 meters or more.

Factors to Consider When Choosing Cast or Extruded Aluminum

Chemical Composition: Different alloying elements impart different properties to aluminum.

Manufacturing Process: Casting is suitable for complex shapes, while extrusion is suitable for continuous production.

Mechanical Properties: Extruded aluminum typically has higher strength and hardness.

Load Bearing: Extruded aluminum performs better under load.

Durability: Both have good durability, but forged aluminum is more wear-resistant.

Cost: Cast aluminum is generally cheaper and suitable for complex-shaped parts, while extruded aluminum is cost-effective for mass production.

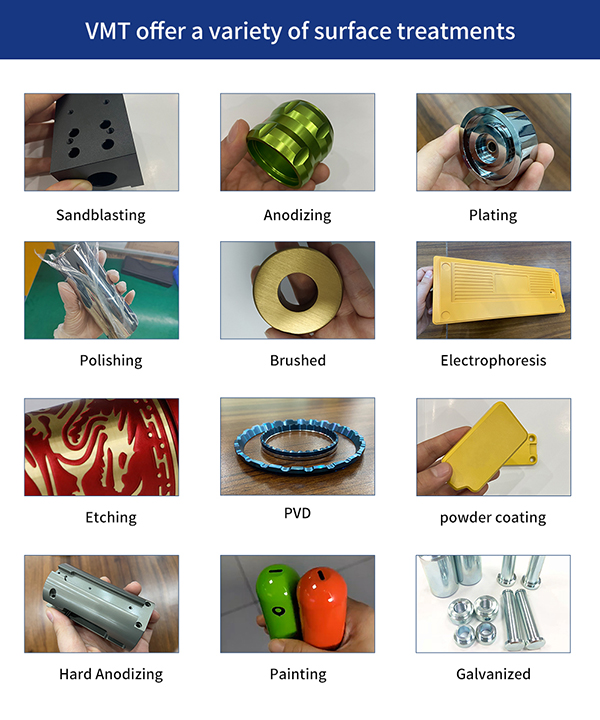

Surface Treatment: Extruded aluminum can undergo surface treatments to enhance corrosion resistance and aesthetics.

Design Flexibility: Cast aluminum is suitable for customized designs, while extruded aluminum is suitable for standardized profiles.

Strength: Extruded aluminum usually has higher tensile and yield strength.

Production Volume: Extruded aluminum is suitable for mass production, while cast aluminum is suitable for small batch or custom production.

Complexity of Shapes: Cast aluminum can produce more complex shapes.

Porosity: Cast aluminum may have porosity issues, while extruded aluminum has lower porosity.

Conclusion:

Cast aluminum and extruded aluminum each have their advantages. The choice depends on specific application requirements, cost-effectiveness, and production efficiency. Cast aluminum is suitable for complex shapes and cost-sensitive applications, while extruded aluminum is ideal for applications requiring high strength and mass production.

Part Shape and Design Complexity:

Cast aluminum can produce parts with complex shapes and fine structures, suitable for any design needs.

Extruded aluminum profiles have uniform cross-sectional shapes, offering continuity and consistency but making it difficult to produce complex internal structures.

Production Volume:

Aluminum casting is more efficient and economical for large-scale production.

Extruded aluminum is better suited for producing a variety of specifications, such as colored metal tubes, bars, profiles, and wire blanks.

Weight and Size:

Extruded aluminum profiles generally have lower density and weight, suitable for applications with strict weight requirements.

Aluminum castings can have their weight and size adjusted as needed to meet different design requirements.

Mechanical Performance Requirements:

Extruded aluminum profiles offer high strength and hardness, suitable for high-pressure and load-bearing situations.

Aluminum castings can improve mechanical performance by adjusting alloy composition and heat treatment processes.

Machinability:

Extruded aluminum profiles are easy to machine and form, allowing for cutting, welding, polishing, and more.

Aluminum castings may be harder to machine due to potential internal defects like pores and shrinkage, affecting machining quality and efficiency.

Surface Finish:

Aluminum castings have smooth surfaces and often require no additional polishing, providing high aesthetic appeal.

The surface finish of extruded aluminum profiles depends on the precision of the extrusion die and subsequent treatment processes.

Mold Manufacturing Cost:

Extruded aluminum profiles have lower mold manufacturing costs due to simpler and more uniform cross-sectional shapes.

Aluminum casting molds are more expensive, especially for complex shapes requiring higher machining precision and cost investment.

Durability and Corrosion Resistance:

Both aluminum castings and extruded aluminum profiles exhibit excellent durability and corrosion resistance.

Aluminum castings can further enhance corrosion resistance through surface coatings, making them more durable in harsh environments.

Process Complexity:

Aluminum extrusion is relatively simple and efficient, suitable for large-scale production.

Aluminum casting is more complex and varied, allowing for choosing the appropriate casting method and process parameters according to different needs.

Price:

Extruded aluminum profiles are usually cheaper due to their production efficiency and cost-control advantages.

Aluminum castings may have higher prices due to mold manufacturing costs and longer production cycles, but unit costs may decrease with large-scale production by reducing scrap rates and increasing efficiency.

Manufacturing Cycle:

Aluminum extrusion has shorter manufacturing cycles due to its continuity and efficiency, quickly responding to market demands.

Aluminum casting, especially for complex parts, may require longer cycles to design molds, adjust process parameters, and undergo multiple trials to ensure product quality.

Material Characteristics:

Extruded aluminum profiles have more uniform material characteristics, as the production process's temperature, pressure, and speed parameters can be precisely controlled, reducing material defects and stress.

Aluminum castings may have material performance differences due to factors like cooling speed, alloy composition, and pouring methods.

Environmental Impact:

Both aluminum extrusion and aluminum casting have energy consumption and waste emissions during production.

With technological advancements and increased environmental awareness, both processes are being optimized to reduce environmental impact through efficient heating equipment, optimized production processes, and waste recycling.

Surface Treatment Requirements:

Extruded aluminum profiles may need anodizing, painting, etc., to enhance corrosion resistance, aesthetics, and functionality.

Aluminum castings may require more complex surface treatments like sandblasting, shot blasting, and electroplating to improve surface quality and performance due to potential surface defects.

Both cast aluminum and extruded aluminum have unique advantages and application scopes in CNC machining parts manufacturing. Cast aluminum is suitable for producing parts with complex shapes and fine structures, especially in scenarios requiring high design freedom. Extruded aluminum, with its lightweight, high strength, and easy machinability, is widely used in standardized and mass-production settings. When choosing a process, consider factors like part shape, design complexity, production volume, mechanical performance requirements, machinability, surface finish, mold manufacturing cost, durability and corrosion resistance, process complexity, price, manufacturing cycle, material characteristics, and environmental impact to ensure the selected process meets project requirements and achieves optimal economic and social benefits.

Is cast aluminum stronger than extruded aluminum?

Not necessarily. The strength of cast aluminum and extruded aluminum depends on factors like alloy composition, heat treatment, and part shape and size. In some cases, cast aluminum can improve strength through optimized alloy composition and heat treatment processes. In other cases, extruded aluminum may offer higher strength and hardness due to its unique production process and cross-sectional shape.

Which is better, aluminum or cast aluminum?

There is no absolute answer as "better" depends on specific application scenarios and needs. Aluminum, as a lightweight, corrosion-resistant, and recyclable metal, is widely used in various fields. Cast aluminum, a form of aluminum processing, offers advantages like complex shapes and fine structures, suitable for specific design requirements. Therefore, the choice should be based on the project's specific requirements.

Is cast aluminum stronger than machined aluminum?

Not necessarily. The strength of cast aluminum and machined aluminum depends on factors like alloy composition, heat treatment, part shape, and size. Machined aluminum, processed through milling, turning, grinding, etc., from aluminum blocks or sheets, may have strength and hardness affected by stress and deformation during machining. Cast aluminum can enhance strength by optimizing alloy composition and heat treatment processes. Therefore, it is not simply stronger than machined aluminum.

What is the most durable type of aluminum?

The most durable type of aluminum depends on specific application scenarios and needs. Different aluminum alloys have unique performance characteristics such as high strength, toughness, corrosion resistance, and thermal conductivity. Choose the most suitable alloy composition and heat treatment process based on the project's specific requirements.

Which aluminum is best for machining?

Suitable aluminum types for machining typically have good cutting performance and post-machining surface quality. Commonly used aluminum types for machining include 6061-T6 and 7075-T6 aluminum alloys, known for their moderate hardness and good cutting performance, maintaining stable machining quality and efficiency.

Is cast aluminum fragile?

Cast aluminum is not necessarily fragile. Its strength and toughness depend on factors like alloy composition, heat treatment, pouring method, and cooling speed. Optimizing these factors can produce high-strength and toughness cast aluminum parts. However, defects like pores and shrinkage in cast aluminum parts may reduce their strength and toughness, so strict control of process parameters and necessary inspections and tests are required during production to ensure product quality.