15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

243 |

Published by VMT at May 18 2024

243 |

Published by VMT at May 18 2024

Introduction:

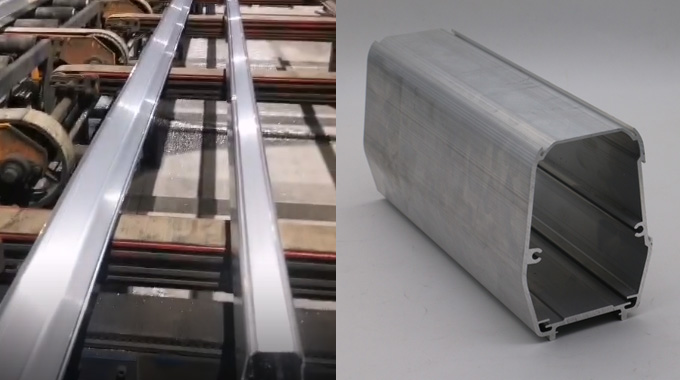

In the field of CNC machining, the aluminum extrusion process has garnered significant attention due to its high precision and efficiency. As a crucial metal forming technology, aluminum extrusion profoundly impacts the manufacturing of aluminum profiles. This article provides a comprehensive breakdown of the aluminum extrusion process, including the definition of aluminum extrusion, direct and indirect extrusion processes, process steps, achievable shapes, influencing factors, and widespread applications of aluminum profiles. It also explores the pivotal role of aluminum extrusion in CNC machining.

1. What is Aluminum Extrusion?

Aluminum extrusion, in essence, is the process of shaping aluminum material into desired cross-sectional profiles under pressure using specific dies. This process not only retains the excellent properties of aluminum such as lightweight and corrosion resistance but also offers a wide range of shape and size options, making it widely used in industries such as construction, transportation, and aerospace.

2. Direct and Indirect Aluminum Extrusion Processes:

Direct Aluminum Extrusion Process:

In the direct aluminum extrusion process, aluminum billets are directly fed into extrusion presses. High pressure applied by the press deforms the billet within the die cavity, filling it to obtain the desired profile. This process is suitable for mass production, offering advantages such as high production efficiency and low cost.

Indirect Aluminum Extrusion Process:

The indirect aluminum extrusion process involves first shaping aluminum billets into prefabricated components of a certain shape before subjecting them to extrusion. This method is suitable for producing aluminum profiles with complex shapes and high precision, albeit at relatively lower production efficiency and higher cost.

3. Step-by-Step Guide to Aluminum Extrusion:

Prepare Extrusion Dies: Design and manufacture suitable extrusion dies based on the desired shape and size of aluminum profiles. Die precision and quality are crucial for the forming effectiveness.

Preheat Aluminum Billets: Heat aluminum billets in a preheating furnace to enhance their plasticity. Preheating temperatures typically range between 400-500 degrees Celsius, adjusted according to the material and thickness of the billets.

Transfer Billets to Extrusion Press: Use mechanical devices to transfer preheated aluminum billets to the extrusion press, ensuring precise alignment between the billets and the dies.

Feed Billets into Extrusion Container: Employ the press's mechanical mechanisms to feed aluminum billets into the extrusion container, preparing them for the extrusion process.

Extrude Material into Dies: Apply high pressure with the extrusion press to force aluminum billets into the dies, causing them to deform and fill the die cavities. During this process, control extrusion speed and pressure to ensure quality and precision of aluminum profiles.

Quench Extruded Parts: After extrusion, quench aluminum profiles to relieve internal stresses and improve material strength and hardness. Quenching temperature and duration vary based on the material and size of the profiles.

Shear Extruded Parts to Workbench Length: Use shearing machines to cut aluminum profiles to lengths suitable for workbench operations.

Cool Profiles to Room Temperature: Cool sheared aluminum profiles to room temperature to stabilize their shape.

Transfer Profiles to Rack and Stretch Align: Move cooled aluminum profiles to racks and stretch-align them using stretching equipment to eliminate residual stresses and improve dimensional accuracy.

Move Profiles to Precision Saw and Cut to Desired Length: Transfer stretch-aligned aluminum profiles to precision sawing machines and cut them to the desired lengths.

Perform Secondary Operations (Heat Treatment, Surface Finishing, and Precision Machining): Conduct secondary operations such as heat treatment, surface finishing, and precision machining as needed to meet specific customer requirements.

4. Shapes Achievable Through Extrusion:

The aluminum extrusion process can produce various shapes and sizes of aluminum profiles, including round tubes, square tubes, rectangular tubes, irregular shapes, rods, and plates. These aluminum profiles not only possess excellent properties such as lightweight, high strength, and corrosion resistance but can also be customized to meet diverse application requirements.

5. Factors Influencing Aluminum Extrusion:

Extrusion Shape: Different extrusion shapes require different die designs and extrusion process parameters. Complex shapes necessitate higher technical requirements and finer process control.

Extrusion Speed: Extrusion speed is a crucial factor influencing the quality and production efficiency of aluminum profiles. Both excessively high and low extrusion speeds may lead to defects or quality issues in aluminum profiles.

Billet Temperature: Billet temperature significantly affects the forming effectiveness and mechanical properties of aluminum profiles. Proper preheating temperatures enhance the plasticity and forming effectiveness of billets, while excessively high temperatures may result in billet burning or oxidation.

Extrusion Ratio: The extrusion ratio refers to the ratio of the cross-sectional area of the billet to the die exit. A higher extrusion ratio makes forming aluminum profiles more challenging but can yield higher mechanical properties and thinner wall thicknesses.

Press Operation: The stability and precision of press operation play a crucial role in the quality and precision of aluminum profiles. Operators need to possess certain skills and experience to ensure the quality and precision of aluminum profiles.

6. Applications of Aluminum Profiles:

Aluminum profiles find extensive applications across various industries, covering almost all sectors requiring lightweight, high-strength, and corrosion-resistant materials. In the construction sector, aluminum profiles are used to fabricate doors, windows, curtain walls, and roofing structures. In transportation, aluminum profiles are utilized in the manufacture of vehicles such as automobiles, trains, and aircraft for their frames and casings. In the aerospace industry, aluminum profiles are indispensable materials used for manufacturing structural components and parts of aircraft and spacecraft. Additionally, aluminum profiles are widely employed in electronics, machinery, home decoration, and other fields.

7. Aluminum Extrusion: An Essential Manufacturing Process:

Aluminum extrusion process serves as a vital manufacturing process that plays an irreplaceable role in modern industrial production. Through the aluminum extrusion process, various shapes and sizes of aluminum profiles can be produced to meet diverse application requirements. Moreover, the aluminum extrusion process offers advantages such as high production efficiency, low cost, and high material utilization, making aluminum profiles a highly sought-after material.

In the field of CNC machining, aluminum extrusion holds significant importance. Through CNC machining technology, aluminum profiles can be processed with high precision and efficiency to produce various complex components and products. Aluminum extrusion CNC machined parts not only boast high precision and quality but also enable rapid and flexible production to meet customers' personalized requirements.

As a professional CNC machining factory, we possess advanced aluminum extrusion equipment and a skilled technical team capable of providing customized aluminum extrusion CNC machined parts and CNC machining services. We prioritize product quality and process innovation, committed to delivering more efficient, precise, and reliable aluminum extrusion CNC machined parts and CNC machining services to customers.

Conclusion:

The aluminum extrusion process serves as a crucial manufacturing process that plays an increasingly significant role in modern industrial production. Through continuous technological innovation and process improvement, we believe that the aluminum extrusion process will find broader applications and development in various fields. As experts in the field of CNC machining, we will continue to focus on providing customers with high-quality aluminum extrusion CNC machined parts and CNC machining services, contributing to the advancement of industrial manufacturing.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!