15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

904 |

Published by VMT at May 19 2024

904 |

Published by VMT at May 19 2024

Introduction:

With the rapid advancement of aerospace technology, the aerospace component machining industry has encountered unprecedented opportunities for development. This article delves into the 13 outstanding enterprises and suppliers in the aerospace component machining manufacturing field over the past decade, analyzing various aspects of aerospace component machining processes and the remarkable performance of these enterprises in this field.

Overview of Aerospace Component Machining Process:

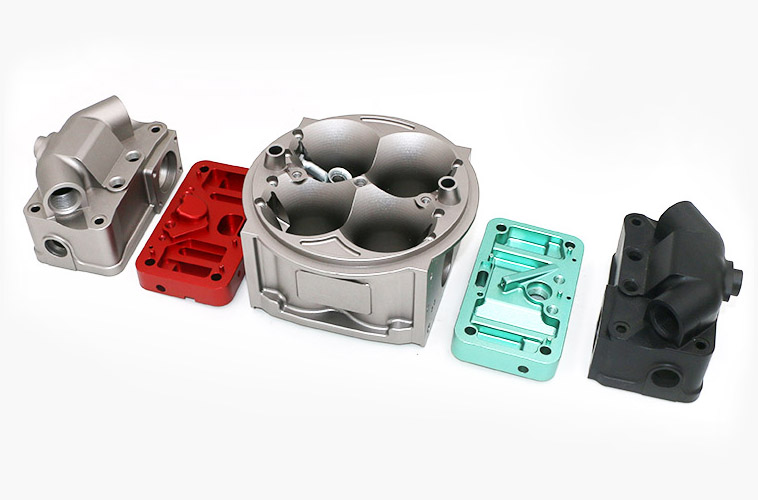

The aerospace component machining process involves the precise and high-quality machining of aerospace components using specific techniques and equipment. This process encompasses material selection, design, manufacturing, testing, and other aspects, significantly influencing the performance, quality, and reliability of aerospace products.

Principles and Characteristics of Machining Process:

The principles of the aerospace component machining process mainly include cutting, forming, heat treatment, surface treatment, and assembly. These interconnected processes collectively determine the final quality of aerospace components. The characteristics of aerospace component machining process mainly manifest in high precision, high quality, high efficiency, and high reliability.

Application Areas:

The aerospace component machining process is widely used in the manufacturing of aircraft, rockets, satellites, and other aerospace products. Key components such as aircraft engines, wings, and fuselages have particularly stringent requirements for aerospace component machining processes.

Top 13 Aerospace Component Machining Manufacturers and Suppliers:

vmtcnc: vmtcnc is a company specializing in precision CNC machining, with advanced machining equipment and a professional technical team. Its aerospace CNC machining parts are highly precise and stable in quality, garnering praise from customers.

machining-custom: machining-custom provides customized CNC machining services covering various fields including aerospace. With exquisite technology and rich experience, machining-custom delivers high-quality precision CNC machining parts for aerospace applications.

Xometry: Xometry is an AI-based on-demand manufacturing service platform offering one-stop precision CNC machining services for aerospace customers. Customers can upload 3D drawings to receive real-time quotes and place orders. With a vast manufacturing network, Xometry ensures the precision and quality of parts, providing fast and reliable machining services.

3D Hubs: 3D Hubs is an online manufacturing platform providing engineers worldwide with access to a global network of manufacturing partners. Its services include 3D printing, CNC machining, and other machining methods, catering to the diverse needs of aerospace component machining.

rapiddirect: rapiddirect offers fast and reliable CNC machining services, covering various industries including aerospace. With efficient production capacity and excellent product quality, rapiddirect has earned wide acclaim from customers.

Boeing: As a leading global aerospace company, Boeing not only manufactures commercial and military aircraft but also has profound accumulations in aerospace component machining manufacturing. Its high-precision machining technology and strict quality control ensure the outstanding performance of components.

Airbus: Airbus, the largest aerospace company in Europe, covers various parts manufacturing in the aerospace component machining field. Airbus focuses on technological innovation and process optimization, committed to providing efficient and reliable machining services.

GE Aviation: GE Aviation is a leading global aircraft engine manufacturer, with outstanding aerospace component machining manufacturing capabilities. The company possesses advanced machining technology and equipment, producing high-quality aerospace engine components.

Pratt & Whitney: Pratt & Whitney is another leading aircraft engine manufacturer, renowned for its aerospace component machining manufacturing business. Pratt & Whitney emphasizes product quality and performance, ensuring that each component meets high standards through rigorous testing.

Rolls-Royce: Rolls-Royce is a renowned British aircraft engine manufacturer, equally strong in aerospace component machining manufacturing. With advanced machining technology and equipment, Rolls-Royce provides personalized machining services for customers.

Precision Castparts Corp. (PCC): PCC is one of the world's leading aerospace component manufacturers, with its products widely used in commercial aircraft, military aircraft, and aerospace engines.

Triumph Group: Triumph Group is a professional aerospace component manufacturer, producing engine components, fuselage structures, and aircraft interiors.

Spirit AeroSystems: Spirit AeroSystems specializes in manufacturing aircraft fuselage and wing systems, with excellent aerospace component machining manufacturing capabilities.

These enterprises and suppliers have significant technical characteristics and service advantages in the aerospace component machining manufacturing field, providing high-quality and efficient machining services for the aerospace industry. With the continuous advancement of aerospace technology and the growing market demand, these companies will continue to play an important role in promoting the sustainable development of the aerospace industry.

Importance and Advantages of Aerospace Component Machining Process:

The aerospace component machining process plays a crucial role in the development of the aerospace industry. It not only affects the performance and quality of aerospace products but also relates to the competitiveness and sustainable development of the entire industry. Compared to other machining methods, the aerospace component machining process has the following advantages:

High Precision: The aerospace component machining process achieves micrometer or even nanometer-level machining precision, ensuring stable and reliable performance of aerospace products.

High Quality: The aerospace component machining process emphasizes product quality and performance, ensuring that each component meets high standards through rigorous testing.

High Efficiency: With advanced machining technology and equipment, the aerospace component machining process achieves efficient and rapid production, shortening the product manufacturing cycle.

High Reliability: After long-term practice and optimization, the aerospace component machining process has formed a stable and reliable machining process and quality assurance system, ensuring the stability and reliability of products.

Conclusion:

Through an in-depth analysis of the top 13 aerospace component machining manufacturers and suppliers over the past decade, we can see the crucial role and significance of the aerospace component machining process in the development of the aerospace industry. These enterprises continuously improve machining precision and efficiency through technological innovation and process optimization, providing strong support for the manufacturing of aerospace products. In the future, with the continuous advancement of aerospace technology and the growing market demand, the aerospace component machining process will continue to play an important role in driving the sustainable development of the aerospace industry.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!