15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

148 |

Published by VMT at Apr 20 2024

148 |

Published by VMT at Apr 20 2024

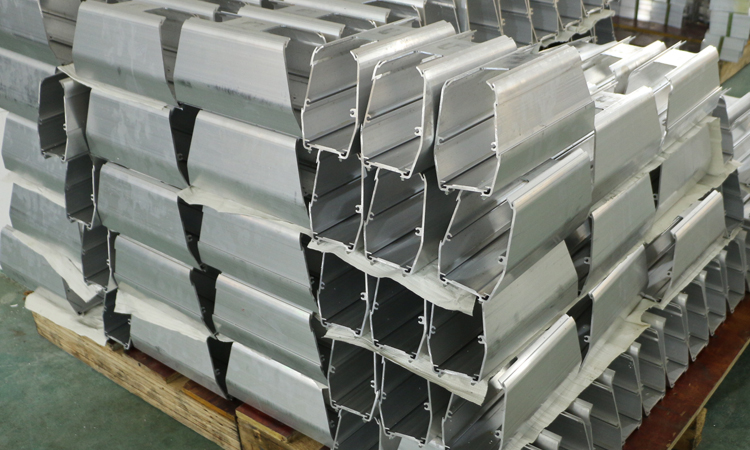

In the field of CNC machining, CNC aluminum shell machining is a crucial process, but the common issue of profile lines during machining can be troublesome. Profile lines not only affect the aesthetics of the aluminum shell but also potentially impact its performance and accuracy. This article will delve into the causes of profile lines in CNC aluminum shell machining and propose effective removal methods to meet the demand for high-precision, high-quality CNC machined parts in machining factories.

I. Causes of Profile Lines

The causes of profile lines in CNC aluminum shell machining are diverse, including:

Improper tool selection: Different aluminum alloy materials with varying hardness and machinability require different types of tools for cutting. Improper tool selection may result in uneven cutting forces during machining, leading to the formation of profile lines.

Inadequate machine tool accuracy: The accuracy and stability of machine tools directly affect machining quality. Insufficient machine tool accuracy or excessive shaking and vibration during machining may lead to profile line formation.

Unreasonable cutting parameter settings: Improper settings of cutting parameters such as cutting speed and feed rate may also result in uneven cutting forces, contributing to profile line formation.

Inadequate cooling and lubrication: Insufficient cooling and lubrication during machining may cause excessive heat generation, leading to oxidation and deformation of the aluminum surface, thereby forming profile lines.

II. Methods to Remove Profile Lines

To address profile lines in CNC aluminum shell machining, the following effective removal methods can be employed:

Selecting appropriate tools and cutting parameters: It is crucial to choose suitable tools based on the characteristics of aluminum alloy materials. Additionally, optimizing cutting parameters such as cutting speed, feed rate, and cutting depth to reduce cutting forces and minimize profile line formation.

Improving machine tool accuracy and stability: Regular maintenance and upkeep of machine tools are essential to ensure optimal working conditions. Moreover, utilizing advanced machine tool design and manufacturing processes, such as full rail design, can minimize machine tool shaking and vibration during machining, thereby reducing profile line formation.

Employing finishing techniques: Finishing techniques are effective methods to remove profile lines. After CNC aluminum shell machining, the machining surface can be refined using sandpaper, grinding machines, etc., to eliminate tool marks and burrs. Care should be taken to control the force and speed of finishing to avoid secondary damage to the aluminum shell.

Surface treatment techniques: In addition to finishing techniques, surface treatment methods can improve the appearance of aluminum shells. For example, anodizing, electroplating, etc., can form a protective film on the surface of the aluminum shell, concealing profile lines and enhancing corrosion resistance and wear resistance. Furthermore, spraying, sandblasting, and other treatment techniques can also improve the surface quality of aluminum shells.

Optimizing process flow and clamping methods: Optimal process flow and clamping methods are equally important in CNC aluminum shell machining. A reasonable process flow can reduce deformation and stress concentration during machining, thereby minimizing profile line formation. Similarly, employing suitable clamping methods to ensure the stability of workpieces during machining can also reduce profile line occurrence.

III. Conclusion and Outlook

The removal of profile lines in CNC aluminum shell machining is a complex and important issue. By comprehensively utilizing various methods and technologies, we can effectively address this problem and provide machining factories with high-quality, high-precision CNC machined parts to meet market and customer demands.

With the continuous development and innovation of CNC machining technology, it is expected that more advanced methods and technologies for removing profile lines will emerge in the future. CNC machining factories should keep abreast of the latest developments in technology and actively introduce and apply these new technologies to continuously improve the quality and efficiency of CNC aluminum shell machining.

Furthermore, machining factories should strengthen employee training and technical exchanges to enhance the skill levels and quality awareness of operators. Only by continuously improving their technical capabilities and management levels can they ensure competitiveness in the fierce market competition.

In summary, the removal of profile lines in CNC aluminum shell machining is a challenging yet critical issue. Through the comprehensive application of various methods and technologies, we can effectively solve this problem, providing machining factories with high-quality, high-precision CNC machined parts to meet market and customer demands.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!