15 years one-stop China custom CNC machining parts factory

460 |

Published by VMT at Jul 25 2024

460 |

Published by VMT at Jul 25 2024

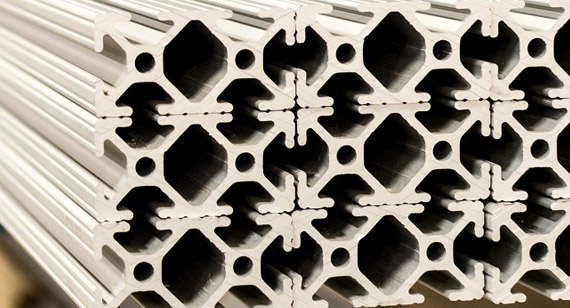

8020 aluminum extrusions is a type of aluminum alloy, not widely recognized as a standardized grade (such as 6061 or 7075), but it may have unique uses in specific industries and applications. Generally, aluminum alloy numbering systems reflect the main alloying elements and their proportions. However, the specific composition of 8020 aluminum extrusions may vary by manufacturer. Typically, this aluminum may contain certain proportions of copper, manganese, magnesium, zinc, and other alloying elements to improve its mechanical properties, corrosion resistance, and machinability. In CNC machining, 8020 aluminum extrusions is used for parts requiring a certain strength, corrosion resistance, and good machinability due to its specific physical and chemical properties.

Good Machinability: 8020 aluminum extrusions performs well in CNC machining, being easy to cut, drill, and mill, making it suitable for complex shapes and precision parts.

High Strength: Compared to pure aluminum, 8020 aluminum extrusions, through alloying treatment, has higher tensile and yield strength, making it suitable for structural parts that require a certain load-bearing capacity.

Corrosion Resistance: Like most aluminum alloys, 8020 aluminum extrusions has good corrosion resistance and can maintain stable performance in various environments.

Lightweight: Aluminum alloys, including 8020 aluminum extrusions, have a lower density compared to other metals like steel and copper, making them suitable for applications where weight is a critical factor.

Poor Thermal Stability: Aluminum alloys have a high thermal conductivity, leading to poor thermal deformation and stability. This is a concern for 8020 aluminum extrusions when used in high-temperature environments.

Relatively Low Hardness: Although 8020 aluminum extrusions has higher strength, its hardness is still lower compared to some high-strength aluminum alloys, making it less suitable for high wear and high impact resistance applications.

Cost Factors: The price of specific grades of aluminum alloys may fluctuate due to market demand and production costs, and 8020 aluminum extrusions is no exception.

It is important to note that "2020 aluminum extrusions" is not a widely recognized grade in standard aluminum alloy naming systems. However, for the sake of this comparison, we can assume that "2020 aluminum extrusions" refers to an aluminum alloy primarily composed of copper, similar to the commonly known 2024 aluminum (a high-strength, high-hardness aluminum alloy widely used in aerospace). Based on this assumption, the following analysis is conducted.

Advantages

High Strength: 2020 aluminum extrusions (assuming similar to 2024 aluminum) has extremely high strength and hardness, making it the material of choice for high-stress components in aerospace, automotive, and other fields.

Good Machinability: Despite its high strength, 2020 aluminum extrusions still has good machinability, making it suitable for complex CNC machining operations.

Excellent Fatigue Resistance: Under alternating stress, 2020 aluminum extrusions exhibits excellent fatigue resistance, making it suitable for dynamic load-bearing structural parts.

Good Corrosion Resistance: With appropriate surface treatment, such as anodizing, its corrosion resistance can be further improved.

Disadvantages

Heat Treatment Sensitivity: High-strength aluminum alloys, like 2024 aluminum, are sensitive to heat treatment processes and require strict control of heating and cooling to achieve optimal performance.

Higher Cost: Due to the high proportion of alloying elements and the higher technical requirements in the processing, the cost of 2020 aluminum extrusions (assuming similar to 2024 aluminum) is usually higher.

Welding Difficulty: High-strength aluminum alloys are prone to hot cracking and stress concentration during welding, requiring special welding techniques and equipment.

Composition and Performance

Composition: 8020 aluminum extrusions's specific composition may vary by manufacturer but generally includes copper, manganese, magnesium, zinc, and other alloying elements. 2020 aluminum extrusions primarily contains copper and may also include magnesium, manganese, and other elements.

Performance: 8020 aluminum extrusions offers balanced strength, corrosion resistance, and machinability, making it suitable for various applications. In contrast, 2020 aluminum extrusions is known for its high strength, hardness, and excellent fatigue resistance, particularly suited for fields requiring extremely high material performance.

Application Fields

8020 Aluminum Extrusions: Suitable for fields requiring certain strength, corrosion resistance, and good machinability, such as automotive components, electronic device housings, and mechanical parts.

2020 Aluminum Extrusions : Due to its high strength and excellent fatigue resistance, it is widely used in aerospace, military equipment, high-performance automotive, and racing applications where extreme loads and stress environments are encountered.

Machinability

8020 Aluminum Extrusions: Exhibits good machinability in CNC machining, with moderate cutting forces, low tool wear, and good surface quality after machining, making it suitable for manufacturing precision parts and complex structures.

2020 Aluminum Extrusions: Also has good machinability, but its high strength and hardness may require higher cutting forces and more wear-resistant tools. Additionally, residual stress after machining may be higher, necessitating appropriate heat treatment or stress relief treatment.

Cost Control

8020 Aluminum Extrusions: Due to its relatively common composition and machinability, production costs and market prices may be relatively low, making it suitable for mass production and cost-sensitive projects.

2020 Aluminum Extrusions: Due to its complex alloy composition, processing difficulty, and specialized market demand, production costs and market prices are typically higher. However, for applications requiring high-performance materials, these costs are often justified.

Choosing between 8020 aluminum extrusions and 2020 aluminum extrusions (assuming similar to 2024 aluminum) depends primarily on your specific needs and application scenarios. If you need a material with moderate strength, good corrosion resistance, and excellent machinability for various CNC machining parts, 8020 aluminum extrusions might be a good choice. However, if you are looking for a material that can withstand extreme loads, has high strength, and excellent fatigue resistance for high-end fields such as aerospace, military, or high-performance automotive, then 2020 aluminum extrusions might better meet your requirements.

Applications of 8020 Aluminum Extrusions

Automotive Manufacturing: Used to manufacture body structural parts, engine brackets, suspension systems, and more.

Electronic Devices: As heat sinks, housings, and internal support components.

Mechanical Equipment: Suitable for making mechanical parts and components that require certain load-bearing capacity and corrosion resistance.

Applications of 2020 Aluminum Extrusions

Aerospace: Used to manufacture critical components such as aircraft fuselage, wings, and landing gear.

Military Equipment: As a material for tank armor, missile components, and other high-strength, high-impact resistance parts.

High-Performance Automotive: Used in racing, sports cars, and other high-performance vehicles for engine blocks, suspension systems, and other key structural components.

When choosing 8020 aluminum extrusions or 2020 aluminum extrusions (assuming similar to 2024 aluminum) for CNC machining parts manufacturing, finding a reliable partner is crucial. A professional CNC machining factory or service provider should be able to offer the following services:

Customized Design: Provide personalized design solutions based on your specific needs and application scenarios.

High-Precision Machining: Use advanced CNC machines and machining techniques to ensure the machining accuracy and surface quality of parts.

Material Consultation: Recommend the most suitable aluminum grades based on your needs and provide professional advice on material properties, machining difficulty, and cost.

Quality Control: Establish a comprehensive quality management system to strictly monitor the machining process and ensure that every product meets quality requirements.

8020 aluminum extrusions and 2020 aluminum extrusions each have their strengths in the field of CNC machining parts manufacturing. The choice depends on your specific needs, application scenarios, and expectations for material performance. By thoroughly understanding the characteristics, advantages, disadvantages, and application fields of both materials, and combining professional consultation and customized services, you can make an informed choice and lay a solid foundation for the success of your project.

What is the Difference Between 8020 Aluminum Extrusions and 2024 Aluminum?

8020 aluminum extrusions is not a widely recognized standardized grade, and its specific composition and performance may vary by manufacturer. 2024 aluminum is a high-strength, high-hardness aluminum alloy widely used in aerospace and other fields. If we consider "2020 aluminum extrusions" as similar to 2024 aluminum, there would be significant differences in composition, performance, and application fields.

How to Choose the Right Aluminum for CNC Machining Parts?

Choosing the right aluminum involves considering multiple factors, including the part's usage environment, load requirements, corrosion resistance, machinability, and cost. It is advisable to work with a professional CNC machining factory or service provider to consult on material selection based on your specific needs.

What is the Extrusion Strength of 2020 Aluminum Extrusions?

The extrusion strength of 2020 aluminum extrusions profiles varies depending on the specific alloy type and heat treatment process. Generally, the extrusion strength of hard aluminum profiles is ≥110MPa for yield strength and ≥240MPa for tensile strength, while for super hard aluminum profiles, it is ≥150MPa for yield strength and ≥310MPa for tensile strength. These values are standard values, and actual product strength may vary based on specific production processes and quality control.

What is the Difference Between 2020 and 4040 Aluminum Extrusions?

The main difference between 2020 and 4040 aluminum extrusions lies in their cross-sectional dimensions:

2020 Aluminum Extrusions Extrusions: Cross-sectional width and height are both 20mm, suitable for applications with moderate load and strength requirements, such as light frames and small equipment brackets.

4040 Aluminum Extrusions: Cross-sectional width and height are both 40mm, providing higher load-bearing capacity and strength, suitable for applications requiring more load-bearing, such as heavy equipment brackets and industrial production line frames.

What is the Strength of 8020 Aluminum Extrusions?

Direct information on the strength of 8020 aluminum extrusions is limited. Based on general experience, 8020 may refer to a specific aluminum profile or alloy grade. The strength of aluminum profiles is closely related to their alloy composition and heat treatment processes. Generally, aluminum alloy strength ranges widely, from tens of MPa to hundreds of MPa. If 8020 aluminum extrusions belongs to the high-strength aluminum alloy category, its strength may approach or exceed the standard of super hard aluminum profiles.

What is the Strongest Aluminum Profile?

The strongest aluminum profile typically refers to those with high strength, high hardness, and good wear resistance. Among aluminum alloys, the 7-series aluminum alloys (such as 7075) are known for their superior strength and hardness, making them commonly used in aerospace, automotive, and other high-strength applications. However, "strongest" aluminum profile does not have an absolute answer as different applications have different performance requirements.

What Type of Aluminum is 8020?

8020 may refer to a specific aluminum alloy grade or profile specification. In aluminum alloy naming systems, different numbers and letter combinations represent different alloy compositions and performance characteristics. Since 8020 is not a widely recognized standard aluminum grade (such as 6061 or 7075), its specific type and performance may need to be determined based on the manufacturer's specific information. Generally, 8020 may belong to a specific-purpose or special-performance aluminum profile.

What is the Strongest Aluminum?

The strongest aluminum typically refers to aluminum alloys with the highest strength and hardness. The 7-series aluminum alloys (such as 7075) are known for their exceptional strength and hardness and are considered some of the strongest aluminum alloys. These alloys usually contain high levels of zinc and undergo appropriate heat treatment to achieve excellent mechanical properties. However, "strongest" aluminum does not have an absolute answer as different applications have different performance requirements. Additionally, with advancements in material science and the emergence of new materials, even stronger aluminum alloys may appear in the future.