15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

151 |

Published by VMT at May 23 2024

151 |

Published by VMT at May 23 2024

1. Overview of Plastic Extrusion

Plastic extrusion, also known as extrusion molding or extrusion, is a critical technology in the field of plastic machining. It involves the interaction of plastic raw materials through an extruder barrel and screw, where they are heated and plasticized under the action of heat and shear forces. Subsequently, they are pushed by the screw to the die head, continuously forming various cross-sectional shapes of products or semi-finished products. This technology is widely used in the production of products such as pipes, profiles, sheets, films, wire and cable coatings, and rubber tires, and is one of the main forms of plastic material machining.

2. Different Types of Plastic Extrusion Processes

Plastic extrusion processes can be divided into multiple types based on different plasticization methods and product forms. Dry extrusion mainly relies on heating to transform plastic raw materials into a melt, with plasticization and compression occurring in the same equipment. The shaping process is simple and suitable for processing most thermoplastic plastics. Wet extrusion, on the other hand, uses solvents to soften the plastic, with plasticization and compression occurring as two separate processes. The shaping process is more complex and is usually used for the extrusion of nitrocellulose and a few cellulose acetate plastics.

3. Types of Plastic Extrusion Machines

Plastic extrusion machines are the core equipment for implementing plastic extrusion processes and can be classified into single-screw extruders, twin-screw extruders, and multi-screw extruders based on the number and structure of screws. Single-screw extruders are suitable for processing a variety of plastics, with simple structure and easy maintenance. Twin-screw extruders, due to the interaction of two screws, can provide stronger shearing and mixing effects, making them suitable for high viscosity and difficult-to-process plastic materials. Additionally, there are special types of extruders such as screwless extruders to meet different CNC machining requirements.

4. Advantages of Plastic Extrusion

Plastic extrusion technology has numerous advantages. Firstly, it has high production efficiency and can achieve continuous production, increasing output. Secondly, products formed by extrusion molding have diverse cross-sectional shapes to meet the needs of different fields. Thirdly, plastic extrusion technology is cost-effective, requiring minimal equipment investment, simple operation, and easy automation. Finally, extruded plastic products have excellent physical and chemical properties, such as lightweight, high strength, corrosion resistance, and good insulation, making them widely used in various fields.

5. Main Applications of Plastic Extrusion

Plastic extrusion technology has a wide range of applications, covering industries such as construction, packaging, wire and cable, automotive, and medical devices. In the construction industry, extruded plastic profiles such as PVC door and window frames and wall panels are favored for their excellent weather resistance and environmental performance. In the packaging industry, extruded products such as plastic bags and plastic boxes are mainstream choices due to their lightweight, easy processing, and low cost. In the wire and cable industry, plastic extrusion technology is used to produce insulation and sheath layers, ensuring the safety and reliability of cables.

6. Choosing the Best Plastic Extrusion Service

When choosing a plastic extrusion service, factors such as equipment performance, process level, product quality, and service quality should be comprehensively considered. A high-quality plastic extrusion service should have advanced extrusion equipment and process technology to provide customers with high-quality and high-precision extruded products. Additionally, service providers should have rich industry experience and professional knowledge to provide customized solutions and quality technical support according to customer needs.

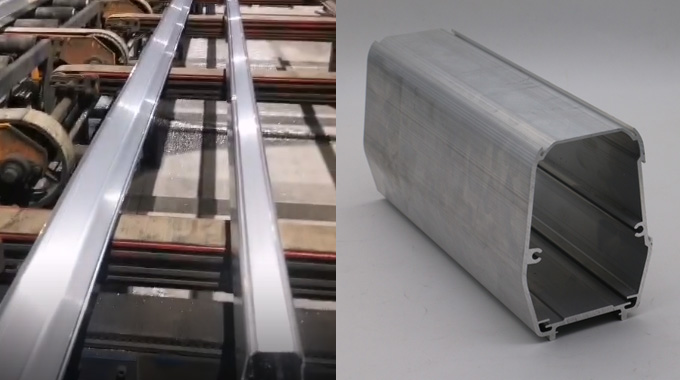

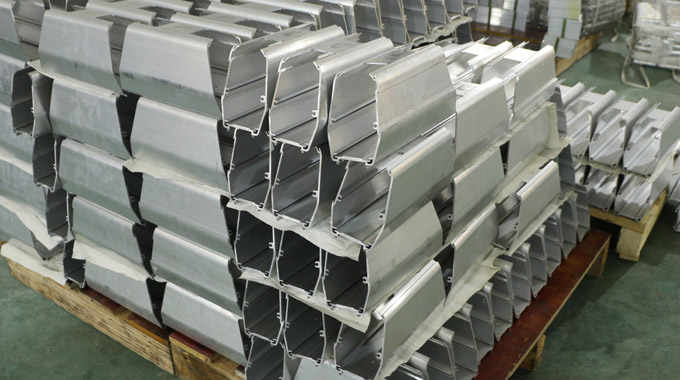

7. Differences Between Plastic Extrusion and Aluminum Extrusion

Although both plastic extrusion and aluminum extrusion are extrusion molding technologies, they have significant differences in material characteristics, process processes, and product applications. Plastic extrusion is mainly suitable for the processing of thermoplastic plastics, with diverse product cross-sectional shapes, lightweight, corrosion resistance, and good insulation. Aluminum extrusion, on the other hand, is mainly used for processing metal materials, with products characterized by high strength, hardness, good thermal and electrical conductivity, and is widely used in aerospace, transportation, and other fields.

8. Conclusion

Plastic extrusion technology, as an important technology in the field of plastic machining, has broad application prospects and market demand. With the advancement of technology and process innovation, plastic extrusion technology will continue to develop towards efficiency, environmental protection, and intelligence. For experts in the field of CNC machining part manufacturing, understanding plastic extrusion technology and its application areas in depth will help improve product quality and processing efficiency, meeting market and customer demands.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!