15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

3527 |

Published by VMT at Sep 14 2021

3527 |

Published by VMT at Sep 14 2021

We have more than 15 kinds of surface finishing, which can make your metal parts have corresponding surface treatments. Many customers have no choice when faced with numerous surface treatment processes, because they do not know the difference between these processes and their functions. This article briefly leads everyone to understand the common surface treatment process guidelines.

Polished

Polishing refers to the use of mechanical, chemical or electrochemical effects to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. It is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece.

Advantages and disadvantages of polishing

Advantages: Polish the metal surface to make the plane smoother and smoother. With a slight reflection.

Disadvantages: There is a certain risk of contamination. The gloss of mechanical polishing will dim over time. When electrochemical polishing is used, the cost will increase and it cannot provide greater resistance and durability.

Applicable materials: suitable for metals with a certain purity, such as chromium, nickel, aluminum, copper, brass, stainless steel, silver and gold.

Anodizing

Anodizing is an electrolytic passivation process that forms an oxide layer on aluminum parts to prevent wear and corrosion, and has a smooth and matte effect.

Advantages: After the surface anodization treatment of metal materials, its corrosion resistance, hardness, wear resistance, insulation, heat resistance, etc. have been greatly improved.

Disadvantages: Because of poor absorption of the coating, high cost, and unsatisfactory coating resistance, it is rarely used in industrial production.

Applicable material: aluminum

Multicolor Anodizing

This is based on anodic oxidation, composite multi-color oxidation or secondary coloring superimposition, in order to achieve the purpose of surface multi-color.

Advantages: Effectively avoid single color tone, and reliably ensure the stability of multi-color appearance. Inherit the advantages of anodizing

Disadvantages: Because of poor absorption of the coating, high cost, and unsatisfactory coating resistance, it is rarely used in industrial production.

Applicable material: aluminum

One method of dyeing black anodizing is to use inorganic salts made of metal to blacken the metal. The second method is to use organic black dyes; organic dyes usually provide limited benefits. One of the main advantages of this anodizing is that the black dye performs better in areas with high light and high heat.

Advantages: good lubricating properties. Black oxidation improves wear resistance, has smaller dimensional changes, slightly improved corrosion resistance, and is cheaper than other coatings.

Disadvantages: Not suitable for materials with a non-black appearance, such as aluminum parts that can cause severe chemical burns.

Applicable materials: steel, stainless steel

Electroplating:

Electroplating is a process for electroplating a thin layer of nickel on metal parts to improve the decorative purpose of the exterior and improve corrosion resistance and wear resistance.

Advantages: It is an environmentally friendly method that does not produce too much pollution.

Disadvantages: It takes a long time and requires more skilled operators.

Applicable materials: a large number of metal and non-metal materials such as aluminum, steel, stainless steel, brass.

Vacuum Plating

Vacuum plating, or PVD, refers to a thin film preparation technology that uses a physical method to deposit materials on the workpiece to be plated under vacuum conditions.

Advantages: can improve durability and resistance to collisions with objects.

Disadvantages: high cost and long-term operation by personnel.

Applicable materials: bronze, copper, aluminum, titanium, stainless steel, etc.

Remove impurities on the surface of the part. Use the pressurized jet of grinding media to apply a matte, uniform finish on the surface of the part.

Advantages: It can be improved in different degrees to greatly improve the bonding force of the workpiece with the paint and the plating material, and the impurities are removed to maintain the smoothness.

Disadvantages: When the pressure is not enough, the roughness will be insufficient and the parts will be easily scratched.

Applicable materials: aluminum, steel, stainless steel, brass, copper.

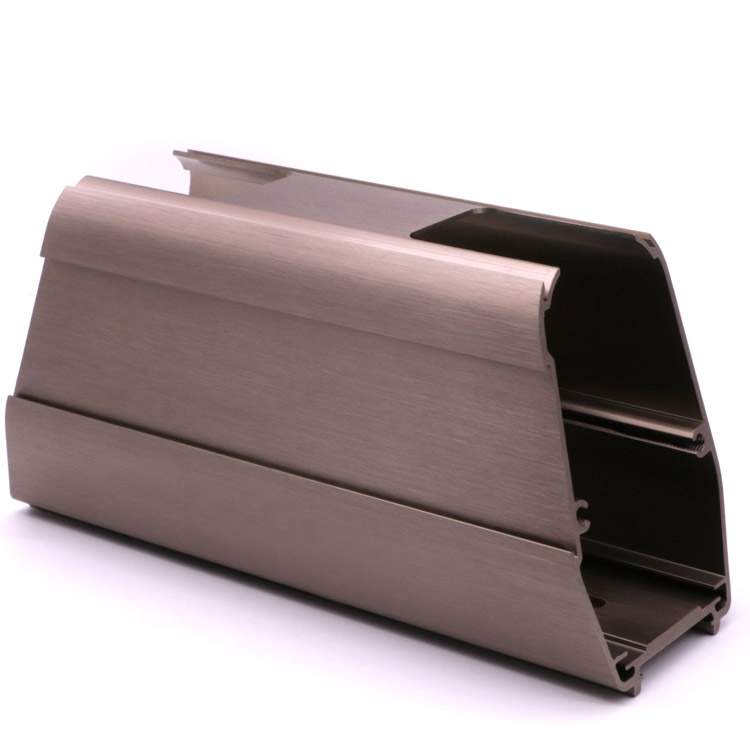

Brushed

By grinding the product to form lines on the surface of the workpiece, it is a surface treatment method that has a decorative effect and can reflect the texture of the metal material.

Advantages: high texture, anti-rust, anti-oxidation, anti-scratch, anti-chemical reagents and anti-smoke properties.

Disadvantages: It is not easy to put in a place with excessive humidity.

Applicable materials: stainless steel, aluminum, copper, iron and other metal products.

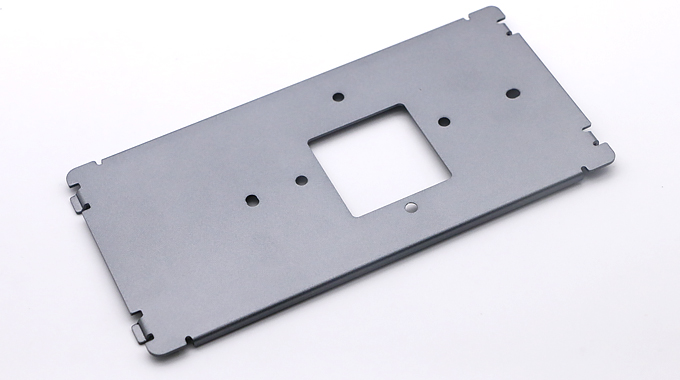

Brush Teeth

Brushing is a pretreatment process on the surface of the material before finishing the surface finishing and protection process. Use sand and gravel to roughen and polish the metal, and use the surface to maintain uniform rules and beautiful lines to achieve the purpose of beautiful parts.

Applicable materials: aluminum, brass, stainless steel, steel

Use chemical or electrochemical methods to produce a colored film or interference film on the metal surface.

Advantages: enhance the corrosion resistance of metals (corrosion-resistant metals are mostly used for coating metals), increase hardness, prevent abrasion, improve conductivity, lubricity, heat resistance, and surface aesthetics.

Disadvantages: reduce the tensile strength of the parts.

Applicable materials: copper, iron, stainless steel, etc.

Powder Coating

Various powder coatings containing metallic pigments (such as copper-gold powder, silver-aluminum powder or mica powder, etc.) are color-matched according to Pantone and the labor color card ral9016.

Advantages: high temperature resistance, wear resistance, additional force.

Disadvantages: The coating is too thick and will cause the performance of the paint film to decrease.

Applicable metal: all metal materials.

How to choose the right surface treatment?

Choose according to function:

Looking for a more comfortable and uniform surface, what matters here is not resistance or durability. On the contrary, this type of finish can provide a better appearance and decoration.

According to color requirements:

Not all metal surface treatments can provide the same color, anodizing process can provide the possibility of obtaining color and other benefits. Therefore, it is useful to combine good resistance with specific aspects.

According to the material:

Generally, aluminum, stainless steel or steel can be used for most processes. When you want to use copper or titanium alloys, you will need the correct procedure. Avoid material discrepancies.

According to the budget:

Last but not least, the necessary budget is another aspect that needs to be considered. Some of the procedures we have listed require high initial costs. In addition, using the right technology can reduce production costs.

Summarize

Choosing different surface treatments for different metals will often result in more costs. This metal surface finishing guide will help you avoid mistakes from the start. The initial cost can be reduced at the beginning.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!