15 years one-stop China custom CNC machining parts factory

2121 |

Published by VMT at Oct 15 2024

2121 |

Published by VMT at Oct 15 2024

Bearings are one of the most essential components in mechanical systems, playing a crucial role in minimizing friction between moving parts and ensuring smooth rotational or linear motion. They are used in virtually every machine, from automobiles and airplanes to industrial machinery and household appliances. This article provides an in-depth look at the different types of bearings, their characteristics, advantages, disadvantages, and applications in various industries, including CNC machining parts manufacturing. Understanding the right bearing type for your application ensures optimal performance, longevity, and cost-efficiency.

A bearing is a machine element that allows for relative motion between two parts while reducing friction. Bearings enable controlled motion—either rotational or linear—while carrying loads. They are typically composed of two rings, rolling elements (such as balls or rollers), and a cage to hold the rolling elements in place. Bearings can be found in every type of machine, ranging from industrial equipment to household appliances.

The main purpose of a bearing is to support loads and allow for the free movement of machine parts with minimal friction. By reducing the resistance between moving surfaces, bearings enhance the operational efficiency of machines and extend their lifespan. Bearings also help in distributing loads evenly, providing mechanical support, and preventing excessive wear on other parts of the machine.

Bearings are critical because they enhance the efficiency and durability of mechanical systems. Without bearings, friction between moving parts would lead to high energy losses, excessive heat generation, and rapid wear and tear. Bearings ensure the smooth operation of machines, reduce energy consumption, and improve the longevity of components. In CNC machining services, bearings play an essential role in ensuring the accuracy and performance of rotating parts.

Key Functions of Bearings:

Reduce Friction: Bearings facilitate rolling instead of sliding, which significantly reduces the friction between moving parts.

Distribute Loads Evenly: Bearings help distribute radial and axial loads, preventing damage to shafts and other components.

Increase Operational Efficiency: By minimizing resistance and energy loss, bearings contribute to the smooth functioning of machines.

Handle Heavy Loads: Bearings are designed to support both heavy radial and axial loads, depending on their type and application.

Improve Durability: Bearings protect machine components from excessive wear, ensuring they last longer and require less maintenance.

1. According to the Presence or Absence of Rolling Elements:

Rolling Bearings: These bearings use rolling elements such as balls or rollers to reduce friction between moving surfaces.

Sliding Bearings: Also known as plain bearings, these bearings do not have rolling elements and instead rely on a sliding motion between surfaces.

2. According to Load Orientation:

Radial Bearings: These bearings support loads that are perpendicular to the shaft.

Thrust Bearings: These bearings handle axial loads, which are parallel to the shaft.

Bearings come in various shapes and sizes, each designed to meet specific mechanical requirements. The selection of a bearing type depends on factors like load capacity, speed, and the type of motion required. Here, we explore the most common bearing types, their advantages, disadvantages, and uses in various applications.

Type 1: Ball Bearings

Ball bearings are the most commonly used type of bearing. They use spherical rolling elements (balls) to maintain the separation between the bearing races. These bearings are ideal for supporting both radial and axial loads, offering low friction and smooth rotational motion.

Ball Bearing Advantages:

Good Wear Resistance: Ball bearings are durable and can last for a long time under normal operating conditions.

Low Friction: Their rolling motion results in minimal friction, leading to low energy losses.

Low Lubrication Requirements: Ball bearings do not need much lubrication and are easy to maintain.

Relatively Inexpensive: Ball bearings are widely available and generally cost-effective.

Can Handle Thrust Loads: These bearings can manage both radial and axial loads efficiently.

Ball Bearing Disadvantages:

Impact Sensitivity: Ball bearings may break if subjected to high impacts.

Noise: They can become noisy, especially at high speeds or when they are not properly lubricated.

Load Limitations: Ball bearings are not suitable for applications with very high loads.

Common Applications:

Automotive: Wheel bearings, steering systems, and transmissions.

Consumer Electronics: Fans and small electric motors.

Industrial Machinery: Conveyor systems and gearboxes.

Deep Groove Ball Bearings

Deep groove ball bearings are versatile and can handle both radial and axial loads. They are known for their high rotational speeds and low friction.

Characteristics:

Compact Size: These bearings are small, making them suitable for tight spaces.

High Rotational Speed: Deep groove ball bearings are ideal for high-speed applications.

Self-Aligning Capability: They can accommodate some degree of misalignment between the shaft and housing.

Self-Aligning Ball Bearings

Self-aligning ball bearings are designed to correct misalignments in the shaft, making them suitable for applications where perfect alignment is difficult to achieve.

Characteristics:

Misalignment Tolerance: These bearings can self-adjust to angular misalignments, reducing wear.

Smooth Operation: They offer smooth and efficient rotation even in imperfect conditions.

Angular Contact Ball Bearings

Angular contact ball bearings are designed to support both radial and axial loads. The contact angle between the balls and the raceway allows for higher axial load capacity.

Characteristics:

High Axial Load Capacity: They can handle higher axial loads compared to other ball bearings.

Directional Support: These bearings are suited for applications where loads are applied in a specific direction.

Thrust Ball Bearings

Thrust ball bearings are designed to carry axial loads exclusively. These bearings are not suitable for radial loads but excel in managing forces parallel to the shaft.

Characteristics:

Low-Speed Applications: Thrust ball bearings are typically used in low-speed applications.

Axial Load Support: They are ideal for applications where axial thrust is the primary load type.

Miniature Bearings

Miniature bearings are small ball bearings used in compact applications requiring high precision.

Characteristics:

Precision: These bearings are used in small devices where high accuracy is crucial.

Low Noise: They are designed to operate quietly, making them ideal for electronics.

Thin-Wall Bearings

Thin-wall bearings have a smaller cross-section compared to standard bearings, making them lighter and suitable for weight-sensitive applications.

Characteristics:

Lightweight: These bearings reduce the overall weight of the machine.

High-Speed Operation: Thin-wall bearings can operate at high speeds without generating much heat.

Flange Bearings

Flange bearings are mounted bearings that provide support for shafts with radial loads.

Characteristics:

Easy Mounting: These bearings come with a flange for easy installation.

High Load Capacity: Flange bearings can handle moderate to heavy loads.

Both thrust bearings and ball bearings have their specific advantages, depending on the type of load and application. The primary difference lies in their load-carrying capacity and the direction of the load.

| Feature |

Thrust Bearings |

Ball Bearings |

| Load Type | Axial loads | Radial and axial loads |

| Speed Capability | Low | High |

| Misalignment Tolerance | Low | Moderate |

| Applications | Low-speed axial load applications | High-speed radial and axial loads |

Roller bearings use cylindrical or tapered rolling elements instead of balls to minimize friction between parts. Roller bearings are typically used for applications involving heavy loads and can handle higher load capacities than ball bearings.

Tapered Roller Bearings

Tapered roller bearings feature tapered rollers and are designed to handle both radial and axial loads.

Features:

Heavy Load Capacity: Tapered roller bearings can support significant radial and thrust loads.

Durable: These bearings are robust and well-suited for high-load applications.

Disadvantages:

Complex Assembly: Tapered roller bearings require precise installation and maintenance.

Usage:

Automotive: Axle systems, gearboxes, and transmissions.

Spherical Roller Bearings

Spherical roller bearings are self-aligning bearings that can handle misalignments while supporting heavy radial and axial loads.

Features:

Self-Aligning: These bearings accommodate misalignment, making them ideal for applications with shaft deflection or misalignment.

High Load Capacity: They are suited for applications with high loads and shock conditions.

Disadvantages:

Size: Spherical roller bearings are larger than other types, which may limit their use in compact applications.

Usage:

Industrial Equipment: Heavy machinery, mining, and power transmission systems.

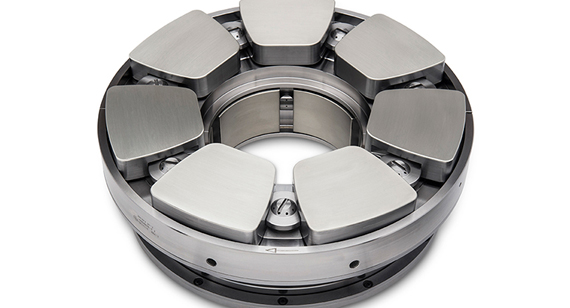

Spherical Roller Thrust Bearings

Spherical roller thrust bearings can support high axial loads along with moderate radial loads.

Features:

High Axial Load Capacity: These bearings are optimized for axial thrust in heavy-duty applications.

Disadvantages:

Low-Speed Applications: They are typically used in low-speed, high-load environments.

Usage:

Heavy Equipment: Construction machinery and gearboxes.

Cylindrical Roller Bearings

Cylindrical roller bearings use cylindrical rollers and are ideal for high-speed and high-load applications.

Features:

High Radial Load Capacity: These bearings excel in supporting heavy radial loads.

Disadvantages:

Axial Load Limitations: Cylindrical roller bearings cannot handle significant axial loads.

Usage:

Electrical Motors: Generators and turbines.

Needle Roller Bearings

Needle roller bearings have long, thin cylindrical rollers, making them ideal for applications where radial space is limited.

Features:

Compact Size: Needle roller bearings are smaller than other roller bearings, making them suitable for tight spaces.

Disadvantages:

Lower Load Capacity: Although compact, needle roller bearings do not handle loads as well as larger bearings.

Usage:

Automotive Transmissions: Gearboxes and planetary gears.

Cross Roller Bearings

Cross roller bearings provide high precision and rigidity, making them ideal for applications requiring fine motion control.

Features:

High Precision: These bearings allow for smooth and precise movement.

Disadvantages:

Limited Load Capacity: While highly precise, cross roller bearings may not handle heavy loads as well as other types.

Usage:

Robotics: Precision instruments and aerospace applications.

Sliding bearings, also known as plain bearings, have no rolling elements. They operate by sliding one surface against another, with lubrication often applied to reduce friction.

Advantages:

Simple Design: These bearings have a simple design and are easy to install.

High Load Capacity: Sliding bearings are capable of handling heavy radial and medium axial loads.

Durability: They are low cost, low noise, and can endure heavy loads and slow speeds.

Disadvantages:

Higher Friction: Sliding bearings produce more friction compared to rolling bearings, which may require more lubrication.

Usage:

Heavy Machinery: Agricultural equipment and hydraulic systems.

For more specific differences, let's look at the comparison chart below:

| Feature |

Plain Bearings |

Ball Bearings |

| Design Complexity | Simple | Complex |

| Lubrication Needs | High | Low |

| Load Capacity | High | Moderate |

| Friction | High | Low |

Fluid bearings rely on a thin film of fluid, usually oil or air, to support the load between the moving surfaces, reducing friction.

Hydrostatic Bearings

Hydrostatic bearings use an external pump to supply fluid pressure, which keeps the surfaces apart.

Advantages:

Zero Wear: Since no solid contact occurs, hydrostatic bearings experience virtually no wear.

Disadvantages:

Complex System: They require external pumps and controls, making them more complex and costly.

Usage:

High-Precision Equipment: Used in applications requiring high accuracy, such as CNC machines and medical devices.

Fluid Dynamic Bearings

Fluid dynamic bearings rely on the motion of the shaft to create a pressure difference that forms a fluid film, separating the surfaces.

Advantages:

Smooth Operation: These bearings offer quiet and smooth operation.

Disadvantages:

Requires High Speed: Fluid dynamic bearings require high shaft speeds to maintain the fluid film.

Usage:

Type 5: Magnetic Bearings

Magnetic bearings use magnetic fields to support the shaft without physical contact.

Types of Magnetic Bearings:

Active Magnetic Bearings: Require external controls to maintain shaft positioning.

Passive Magnetic Bearings: Do not require external power, relying solely on permanent magnets.

Usage:

Aerospace and Turbo Machinery: Magnetic bearings are used in high-speed and high-temperature environments.

Bearings are used in various industries, including:

Automotive: Wheel hubs, transmissions, and engines.

Aerospace: Jet engines, landing gear, and flight control systems.

Industrial Machinery: Conveyor systems, gearboxes, and electric motors.

Consumer Products: Home appliances and electronic devices.

When selecting a bearing, consider the following:

Load Capacity: Choose a bearing that can handle the maximum load.

Speed Requirements: Ensure the bearing can operate efficiently at the required speed.

Rotational Accuracy: Some applications demand high precision, requiring bearings with minimal runout.

Operating Environment: Bearings used in harsh environments need to resist contamination and corrosion.

Noise Requirements: Some applications, like fans and medical devices, require bearings that operate quietly.

Radial Space: Consider the available space for the bearing.

Bearing Stiffness: High-stiffness bearings are needed for high-precision applications.

Bearing Vibration: Excessive vibration can reduce bearing life and performance.

Bearings are made from both metallic and non-metallic materials:

Metallic Materials: Steel, stainless steel, and ceramics are commonly used for bearings.

Non-Metallic Materials: Plastics and composites are used in applications where corrosion resistance and lightweight materials are required.

When selecting the right bearing, consider:

Loading: Understand the type of load (radial or axial) the bearing will handle.

Speed: Choose a bearing that can handle the required operational speed.

Accuracy: High-precision bearings are necessary for fine-motion applications.

Rigidity: Applications requiring high rigidity should use bearings with minimal deflection.

Bearings are essential components in almost every mechanical system, ranging from small household appliances to large industrial machines. Understanding the various types of bearings, their characteristics, and their applications is crucial for selecting the right bearing for your specific needs. At VMT, we specialize in providing custom CNC machining services, ensuring that our clients receive high-quality CNC machined parts that meet the highest standards of precision and performance.

What are the 5 types of bearings?

The five main types of bearings are ball bearings, roller bearings, fluid bearings, magnetic bearings, and sliding bearings.

What is the most common type of bearing?

Ball bearings are the most common type of bearing, used in a wide variety of applications due to their versatility.

What is the strongest type of bearing?

Tapered roller bearings are among the strongest, as they can handle heavy radial and axial loads.

What is the most popular bearing?

Deep groove ball bearings are the most popular, thanks to their low friction, versatility, and ease of use.

What type of bearing has the longest service life?

Fluid bearings generally have the longest service life since there is no direct contact between the moving surfaces, reducing wear.

How to identify the type of bearing?

You can identify bearings by their size, shape, and the type of rolling element (balls, rollers, etc.), as well as by checking their model number or technical specifications.

What are the main categories of bearings?

The main categories of bearings are rolling bearings (ball and roller bearings) and sliding bearings (plain bearings).